Image sensor and forming method thereof

An image sensor and graphics technology, applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of easy saturation of white pixels and lower utilization rate of pixel area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

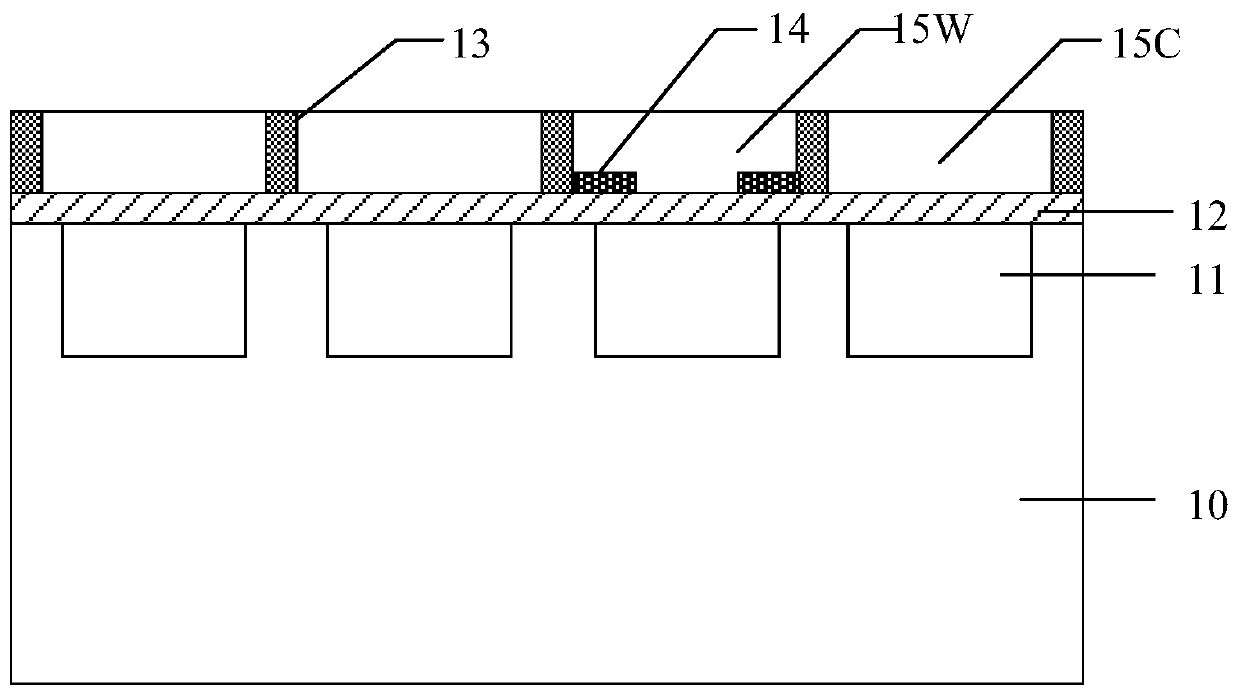

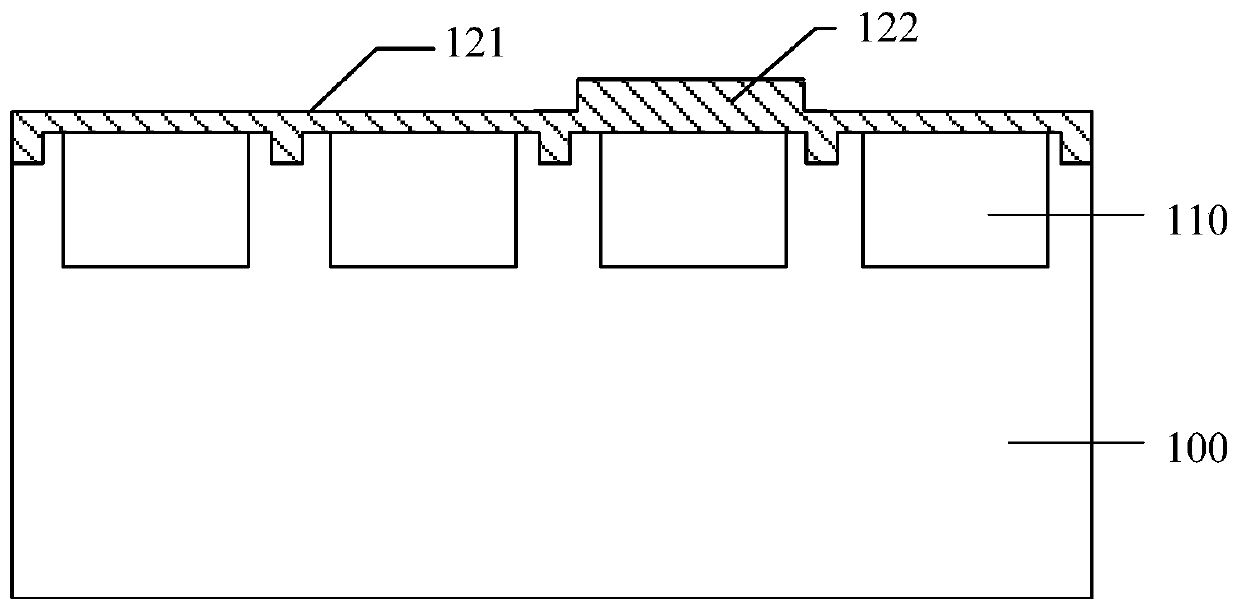

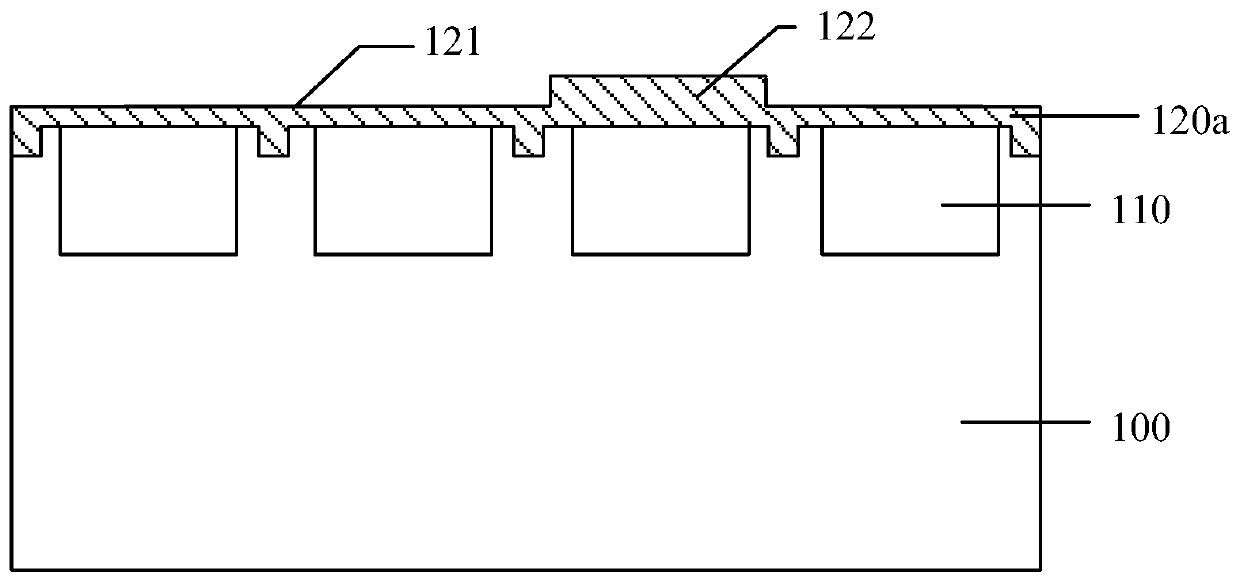

[0033] Figure 2 to Figure 6 is a schematic cross-sectional structure diagram corresponding to each step in the method for forming an image sensor according to the first embodiment of the present invention.

[0034] refer to figure 2 First, a semiconductor substrate 100 formed with discretely arranged photodiodes 110 is provided, the semiconductor substrate 100 includes several pixel regions, the several pixel regions have white pixel regions, and the photodiodes 110 correspond to each pixel region.

[0035] In this embodiment, the semiconductor substrate 100 may be a silicon substrate, or germanium, silicon germanium, silicon carbide, gallium arsenide, or indium gallium, or a silicon-on-insulator substrate or a germanium-on-insulator substrate. The substrate, or the substrate on which the epitaxial layer is grown. The semiconductor substrate 100 includes a photodiode 110 for converting received optical signals into electrical signals.

[0036] In this embodiment, accordin...

no. 2 example

[0067] Figure 7 to Figure 11 is a schematic cross-sectional structure diagram corresponding to each step in the method for forming an image sensor according to the second embodiment of the present invention.

[0068] refer to Figure 7 Firstly, a semiconductor substrate 200 formed with discretely arranged photodiodes 210 is provided, the semiconductor substrate 200 includes several pixel regions, the several pixel regions include white pixel regions, and the photodiodes 210 correspond to each pixel region.

[0069] In this embodiment, the semiconductor substrate 200 may be a silicon substrate, or germanium, silicon germanium, silicon carbide, gallium arsenide, or indium gallium, or a silicon-on-insulator substrate or a germanium-on-insulator substrate. The substrate, or the substrate on which the epitaxial layer is grown. The semiconductor substrate 200 includes a photodiode 210 for converting received optical signals into electrical signals.

[0070] In this embodiment, acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com