Desulfurization and dust removal device

A technology of desulfurization, dust removal and demister, which is applied in the field of flue gas purification, can solve the problems of poor dust removal and purification effect, achieve the effect of reducing the content of particulate matter, improving the ability of dust removal and mist removal, and inhibiting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

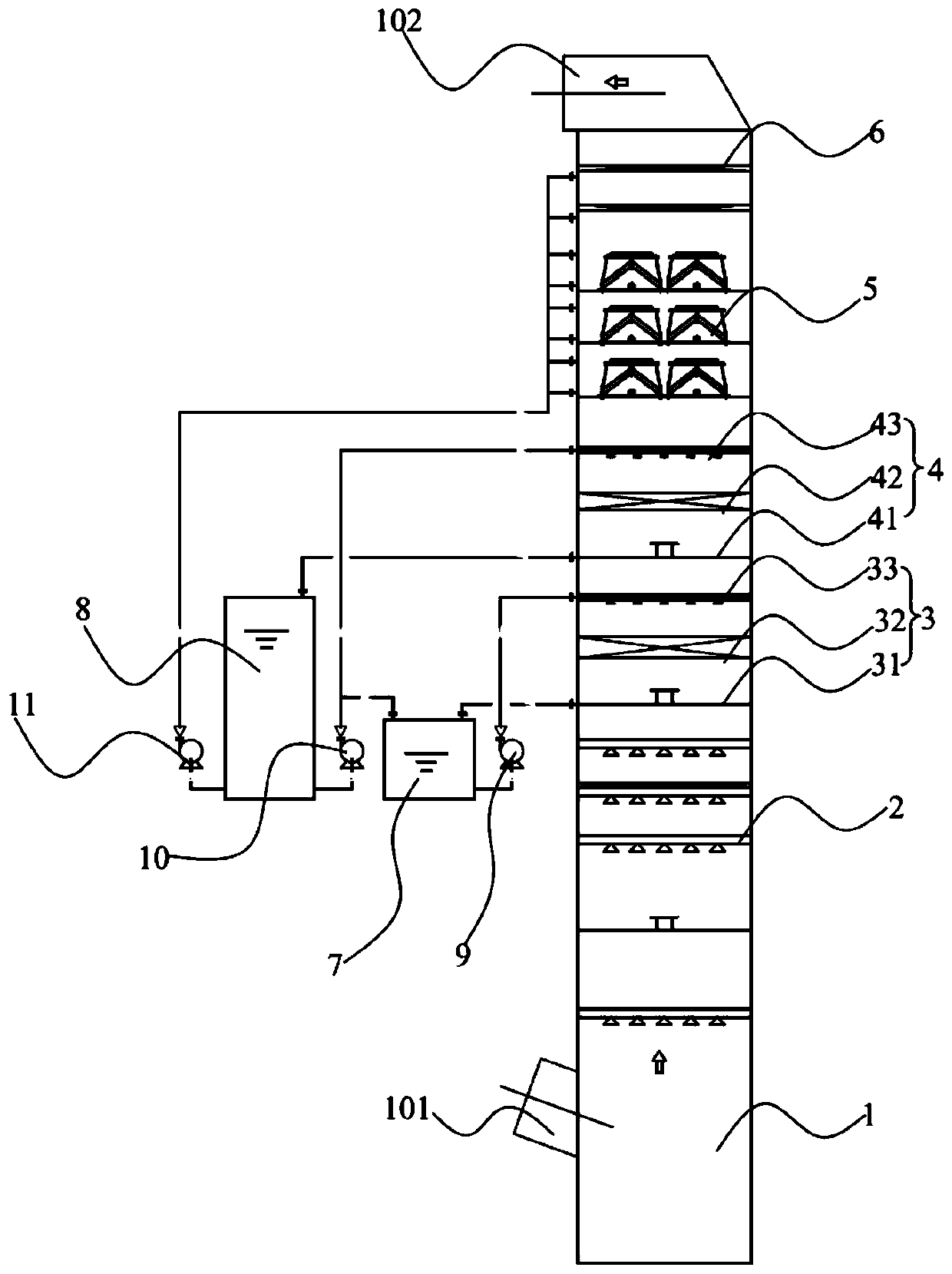

[0051] Such as Figure 1 to Figure 3 A specific implementation of the shown desulfurization and dust removal device includes:

[0052] The main body 1 is provided with an inlet 101 and an outlet 102 ; the spray structure 2 is arranged in the absorption tower and is arranged near the inlet 101 . After the flue gas enters the main body 1 from the inlet 101, it first passes through the spray structure 2, and desulfurizes the flue gas through the spray structure 2.

[0053] The specific implementation of the spray structure 2 is not limited, and it can be various spray structures 2 used in desulfurization and dust removal devices in the prior art.

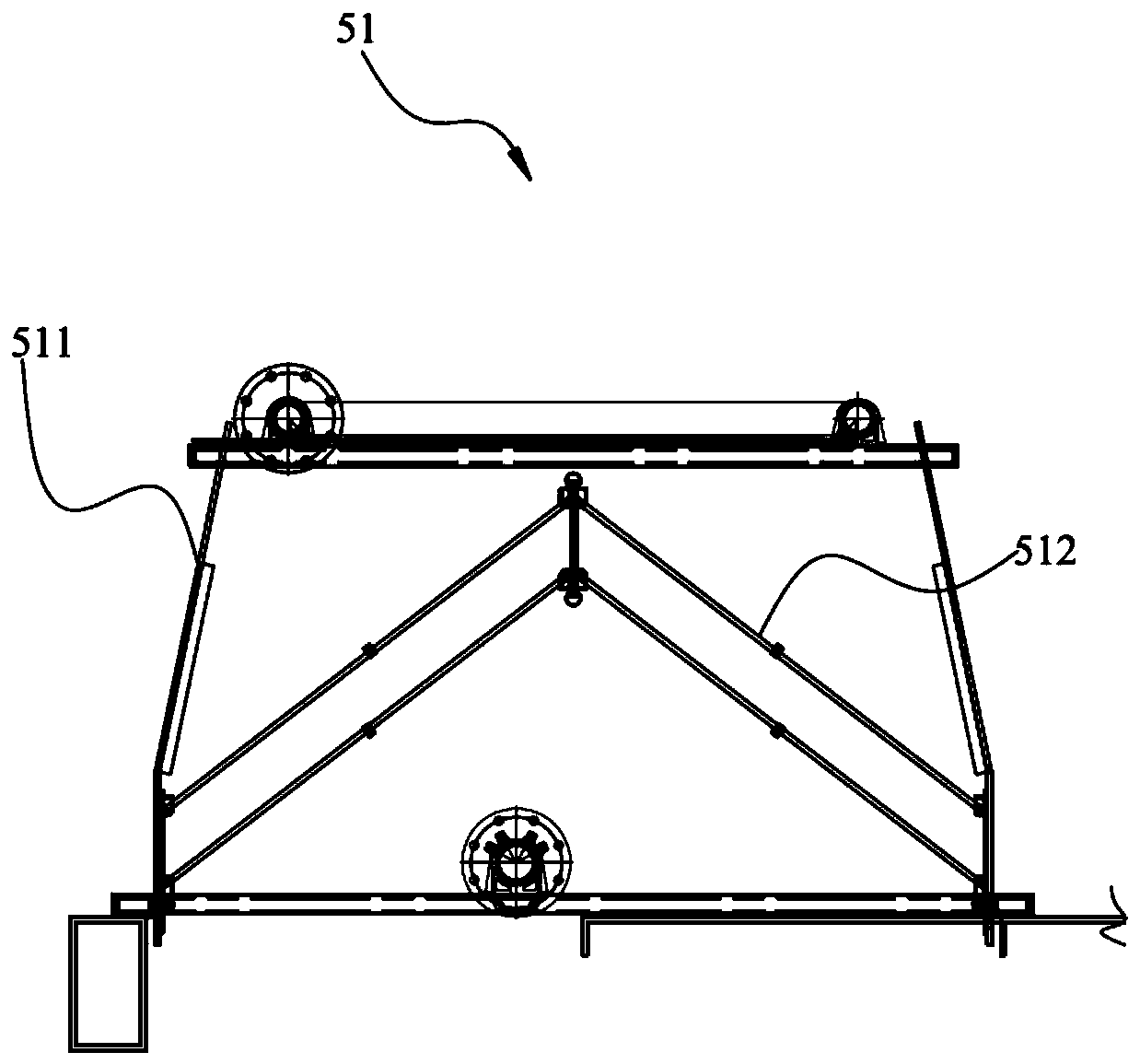

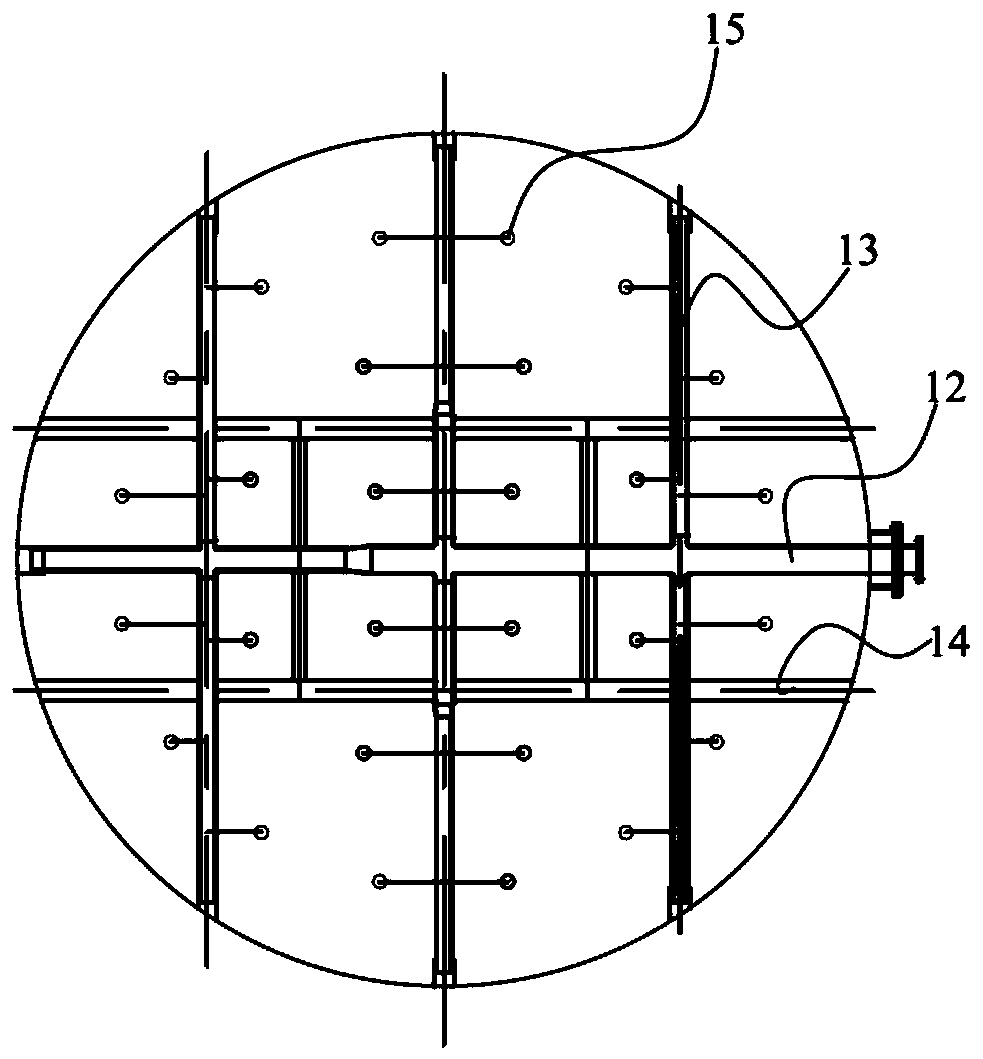

[0054] The purification structure is set in the absorption tower, including the first-level washing component 3, the second-level washing component 4, the dust and mist removal component 5, and the defoaming component 6. The flue gas passes through the spray structure 2 and the first-level washing component 3 from the inlet 101 in seq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com