Method for stabilizing cadmium in industrial waste through mullite

A technology for industrial waste and waste, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of long curing time, large volume, cumbersome operation steps, etc., and achieve strong anti-acid leaching performance , Reduce the leaching rate of cadmium, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

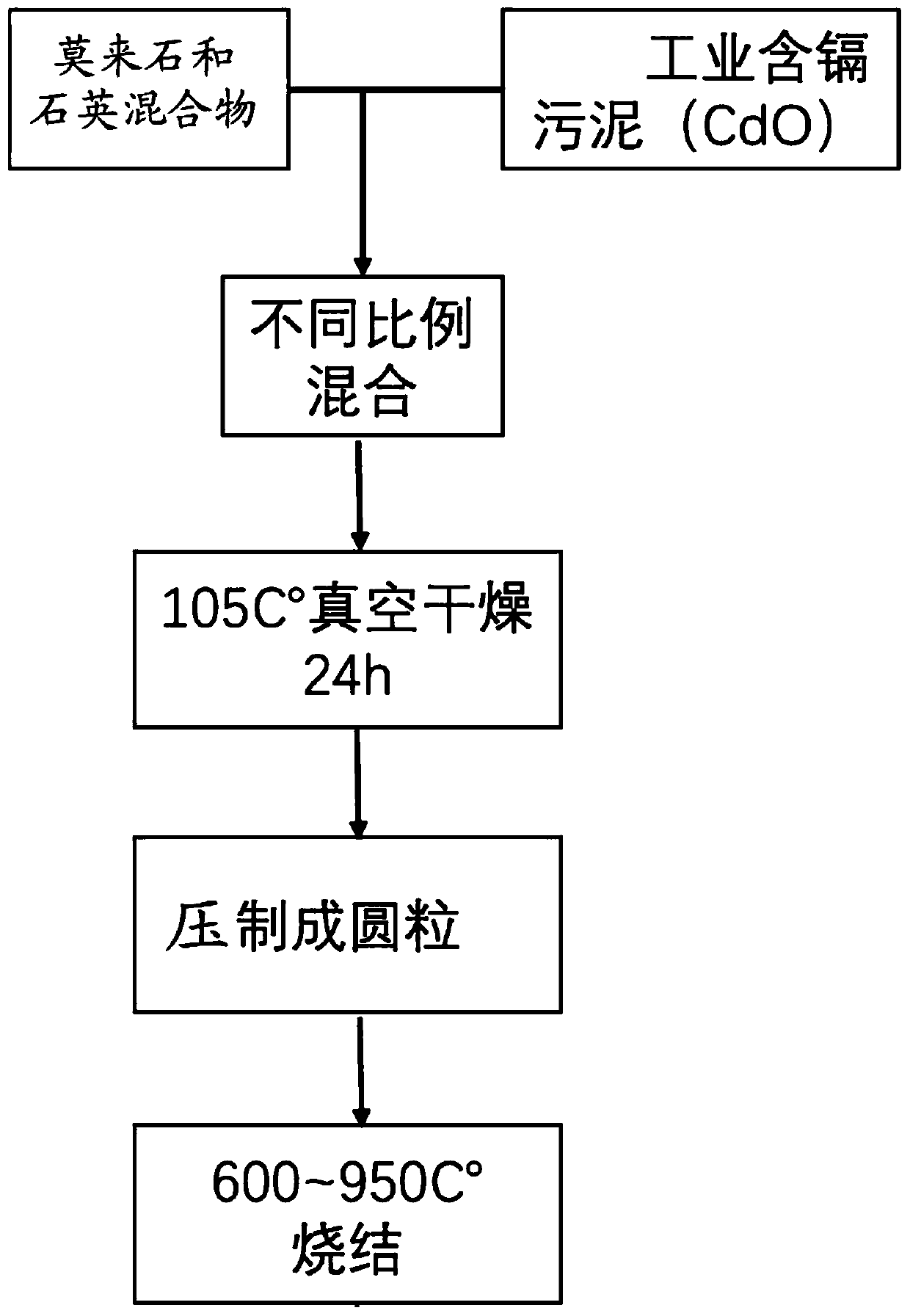

[0034] As a method of utilizing mullite to stabilize cadmium in industrial waste as an embodiment of the present invention, the method comprises the following steps:

[0035] (1) Combine cadmium-containing industrial waste with mullite (3Al 2 o 3 ·SiO2 2 or 2Al 2 o 3 ·SiO2 2 ) and quartz (SiO 2 ) mixture is uniformly dispersed after mixing, and dried to obtain a mixed raw material;

[0036] (2) The raw material obtained in step (1) is compressed into 20mm round particles under an axial pressure of 250MPa to obtain a molding material;

[0037] (3) Sintering the molding material obtained in step (2) at 950° C. for 3 hours to obtain the final product;

[0038] Wherein, in the step (1), the amount of the mixture of mullite and quartz is: the molar ratio of the cadmium element in the cadmium-containing industrial waste to the silicon element in the mixture of mullite and quartz is 1:1.

Embodiment 2

[0040] As a method of using mullite to stabilize cadmium in industrial waste according to an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that in step (3), the sintering temperature is 600°C.

Embodiment 3

[0042] As a method of using mullite to stabilize cadmium in industrial waste according to an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that in step (3), the sintering temperature is 650°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com