Numerical control press control system and working method thereof

A control system and press technology, applied in presses, manufacturing tools, metal processing, etc., can solve the problems of no circuit control system, long push rod stroke of presses, low press-fitting efficiency, etc., to achieve good versatility, shorten Effect of press-fitting stroke and improvement of press-fitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

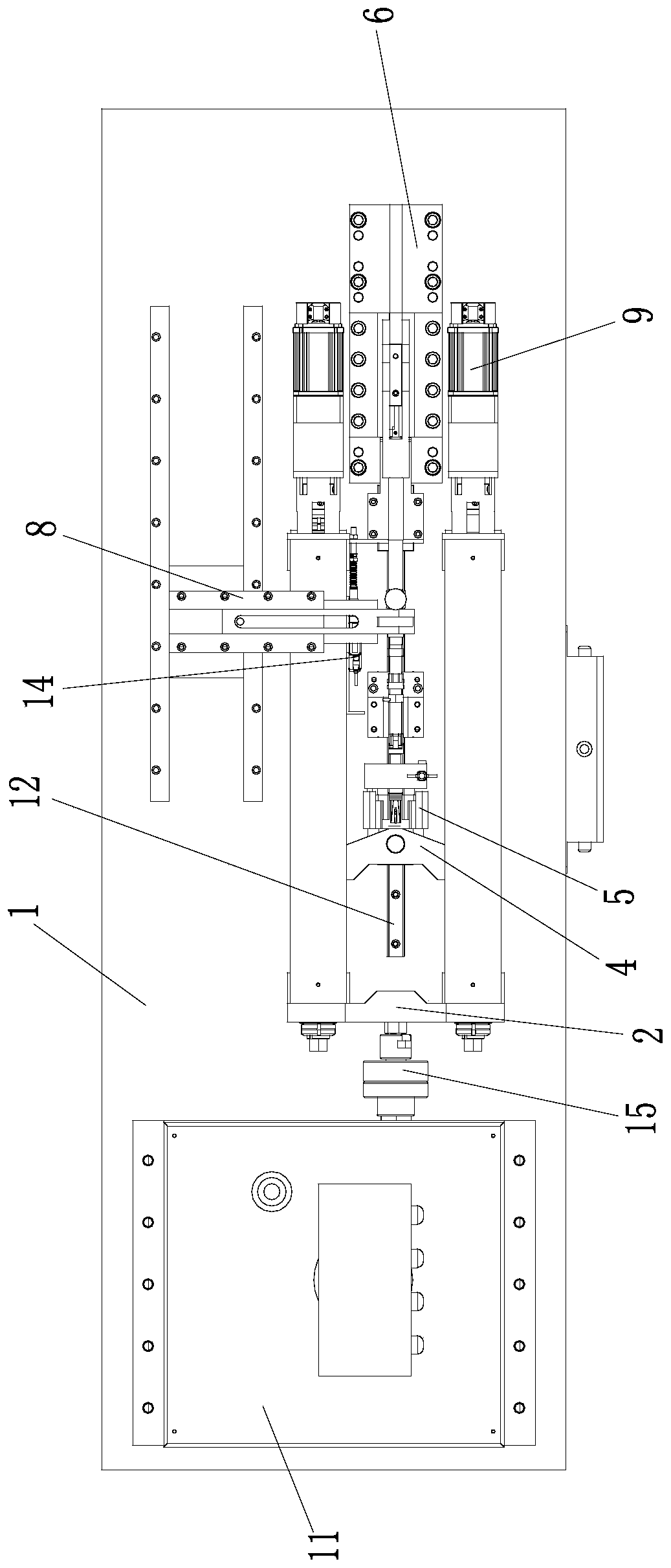

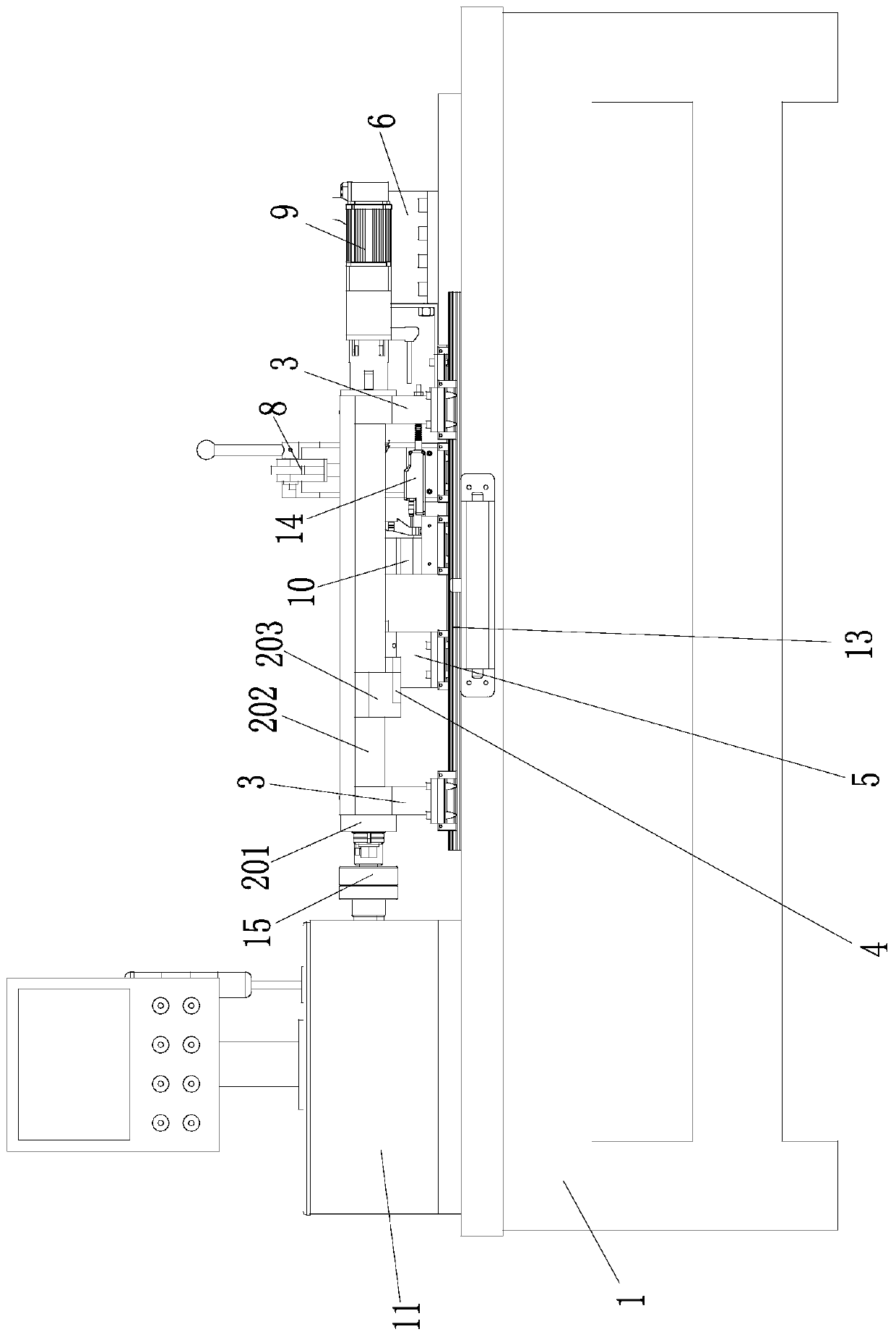

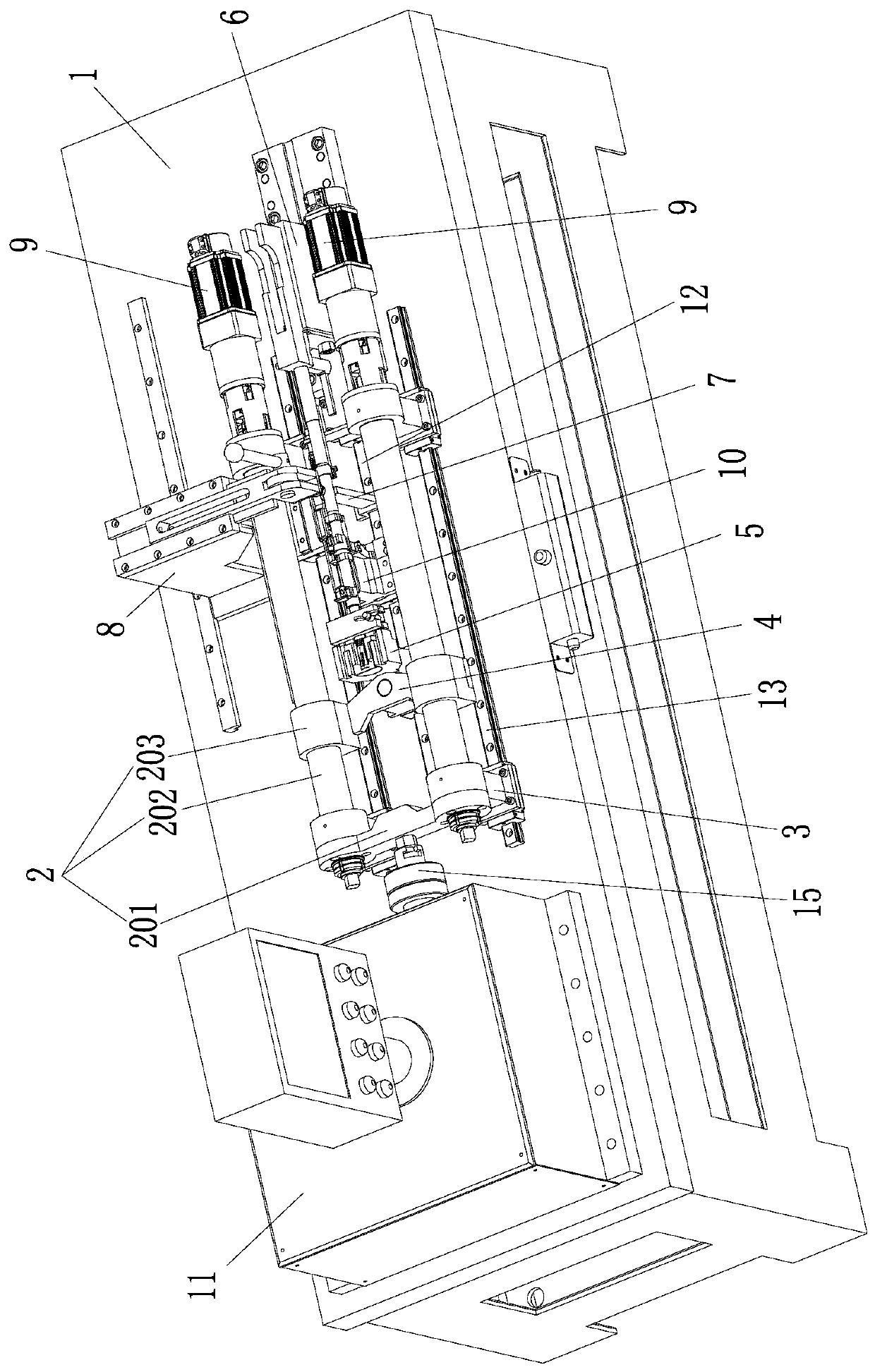

[0031] Such as Figure 1 to Figure 3As shown, a CNC press control system is mainly composed of a workbench 1, a servo electric cylinder 11, an intermediate slide rail 12, two screw rod slide rails 13, a barrel positioning device and a press-fitting mechanism. The workbench 1 is composed of a machine The frame is made of steel welded parts, and the table is a rectangular steel casting with good rigidity. The table is installed on the frame by bolts. The upper surface is finely ground and has high flatness. The servo electric cylinder 11 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com