Superposed group water inlet lifting pump room

A technology for lifting pumps and pump houses, which is applied in pumping stations, water supply devices, buildings, etc. It can solve the problems of increasing water treatment structures, production and operation safety, tight comprehensive layout of plant plane pipelines, and low land utilization rate of structures, etc., to achieve optimization The effect of process pool design, improvement of water supply safety guarantee rate, and increase of land utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0043] The following examples are only examples for clearly illustrating the present invention, rather than limiting the implementation of the present invention. For those of ordinary skill in the art, on the basis of the following descriptions, other different forms of changes or changes can also be made, and these obvious changes or changes that belong to the spirit of the present invention are still within the protection scope of the present invention middle.

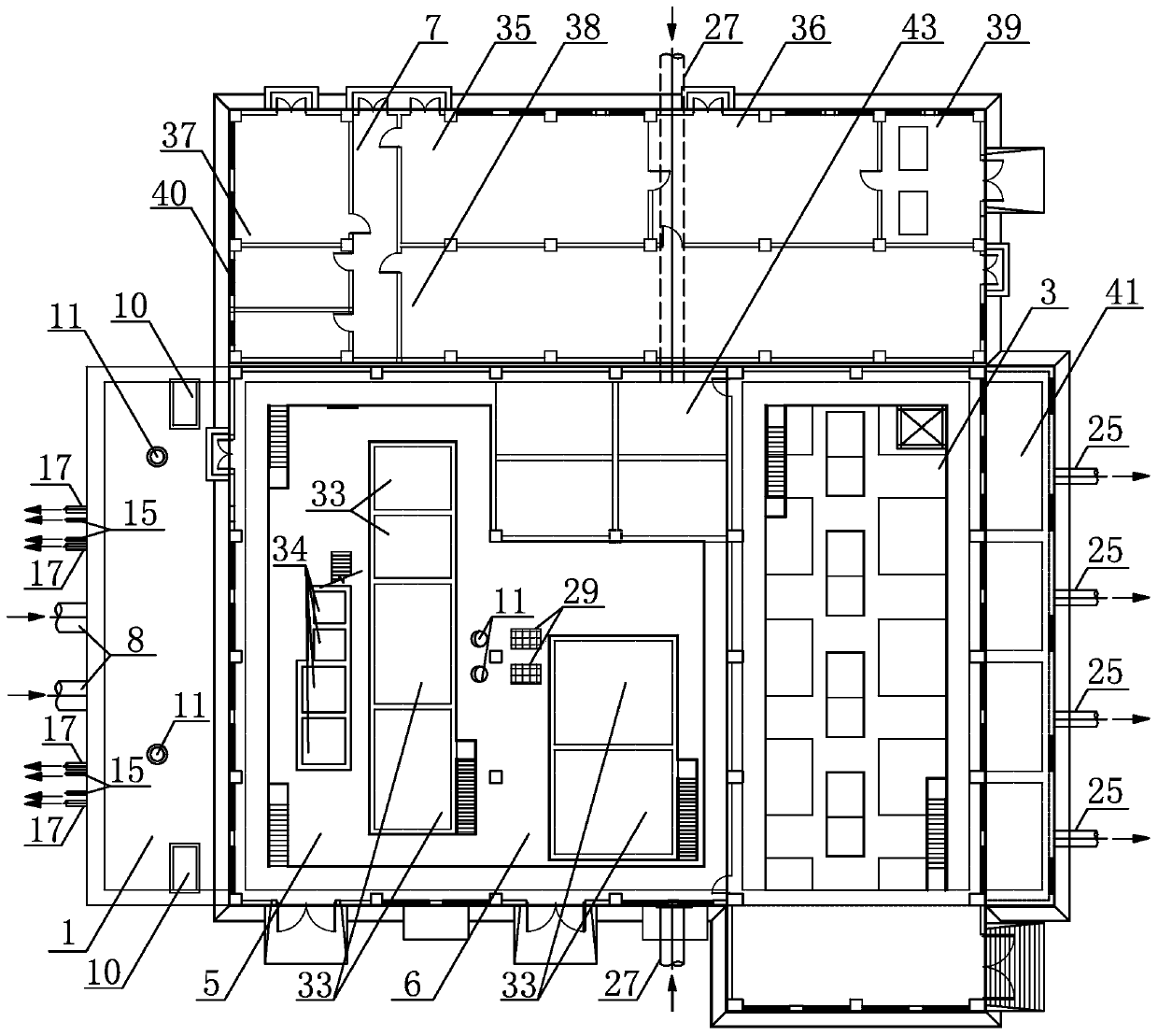

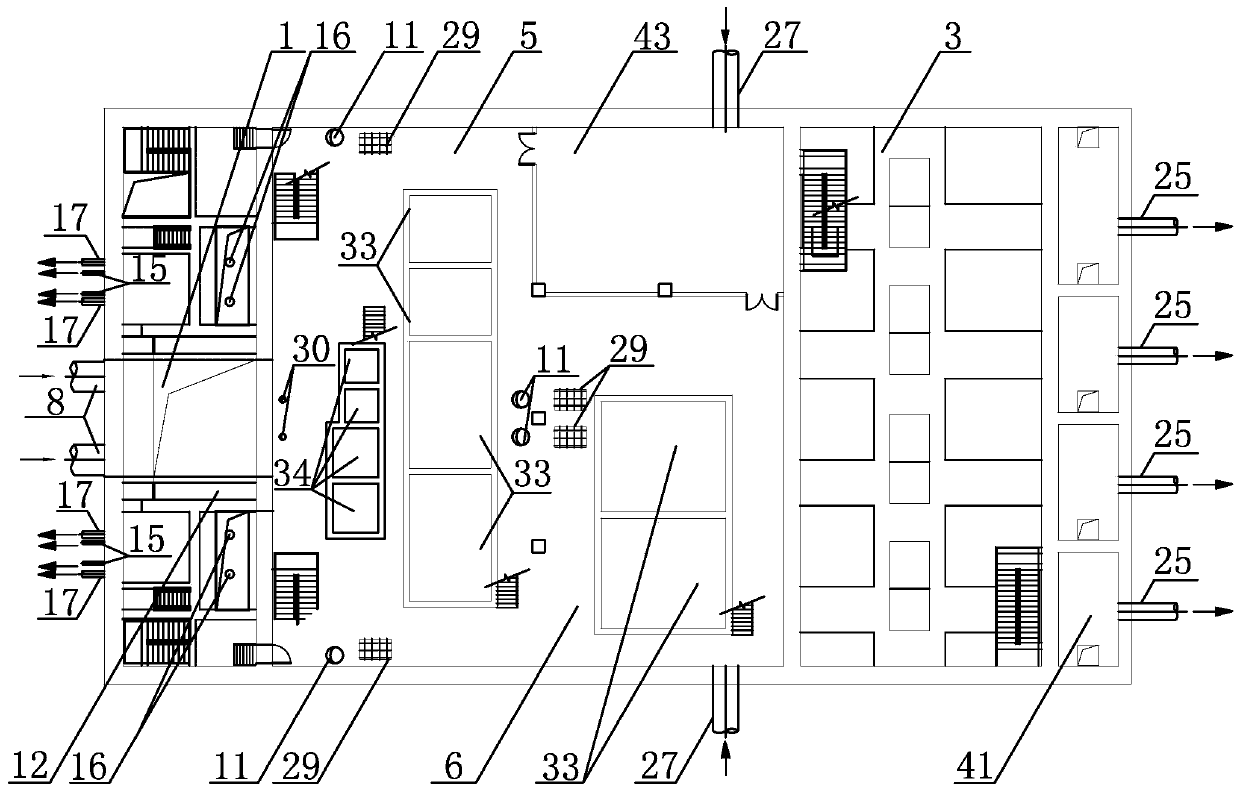

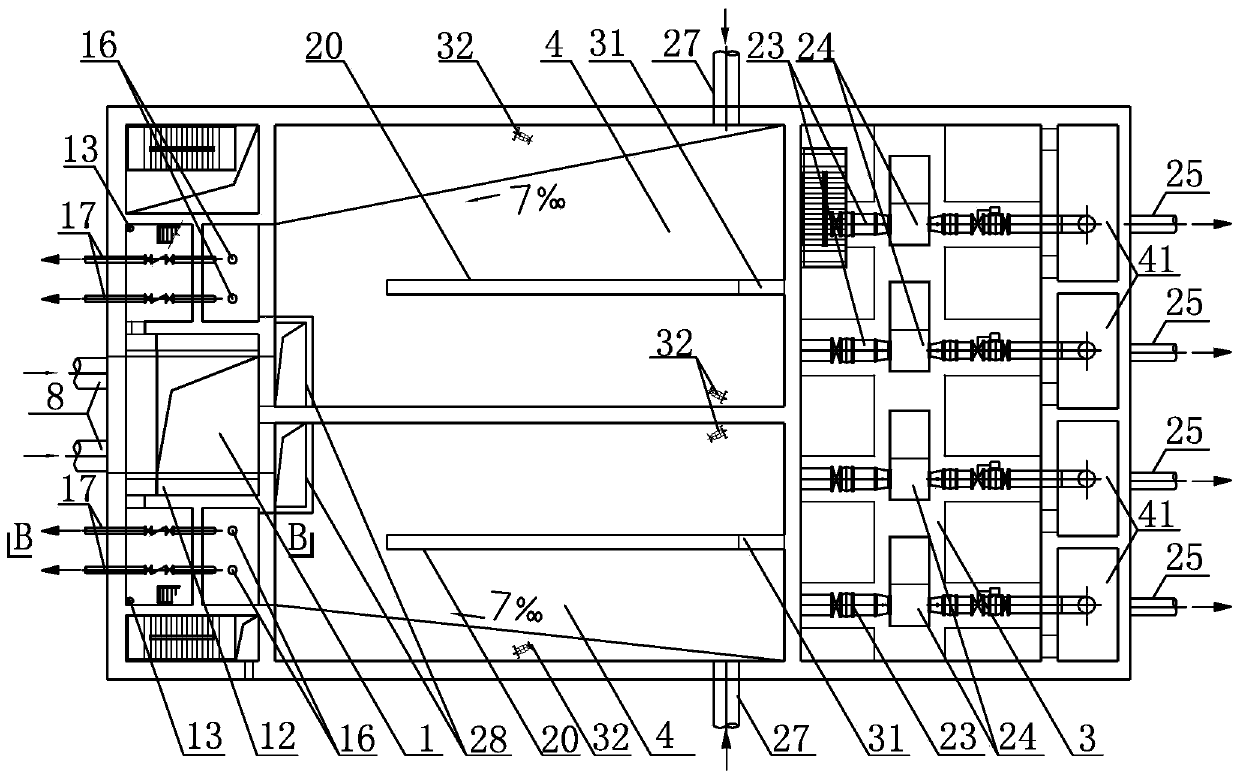

[0044] Refer to each figure, a superimposed group water inlet lifting pump room, including water inlet valve room 1, sump 2, lifting pump room 3, waste water recovery pool 4, sodium hypochlorite pre-dosing room 5 and dosing room 6, distribution Electric room 7;

[0045] see Figure 5 , the water collection pool 2, the waste water recovery pool 4, the sodium hypochlorite pre-dosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com