Gear residual life prediction method based on MMALSTM

A prediction method and gear technology, applied in the fields of instrumentation, computing, electrical and digital data processing, etc., can solve the problems of wasting computing resources, limited long-term information storage capacity, affecting the speed and accuracy of neural network model training, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

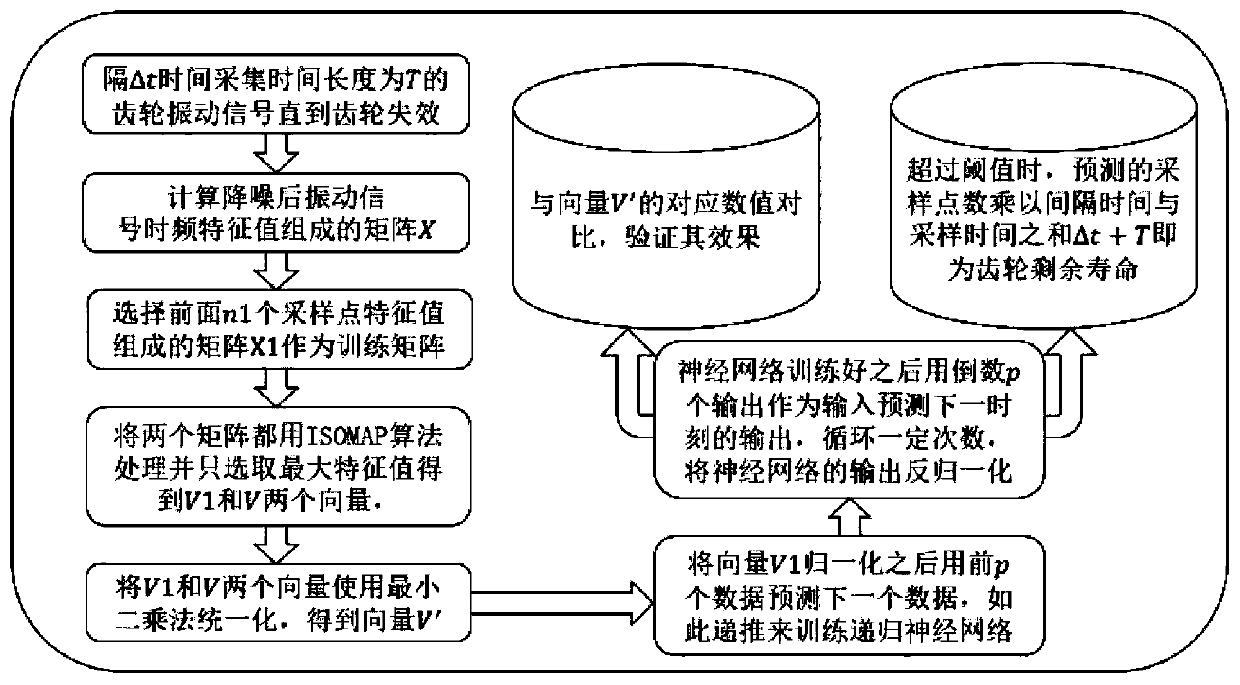

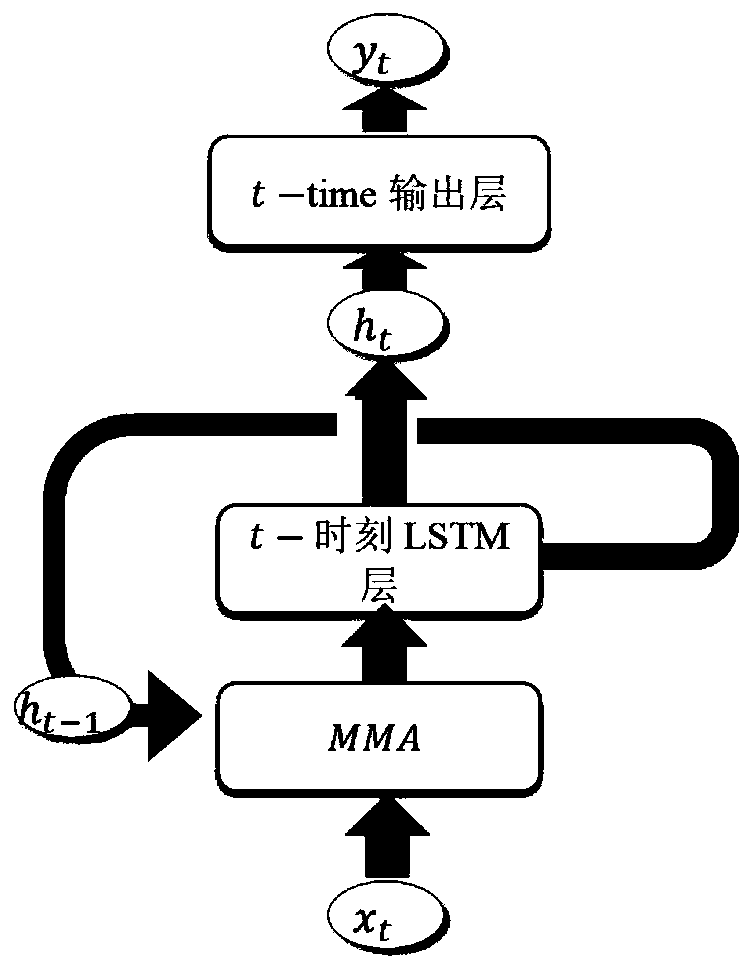

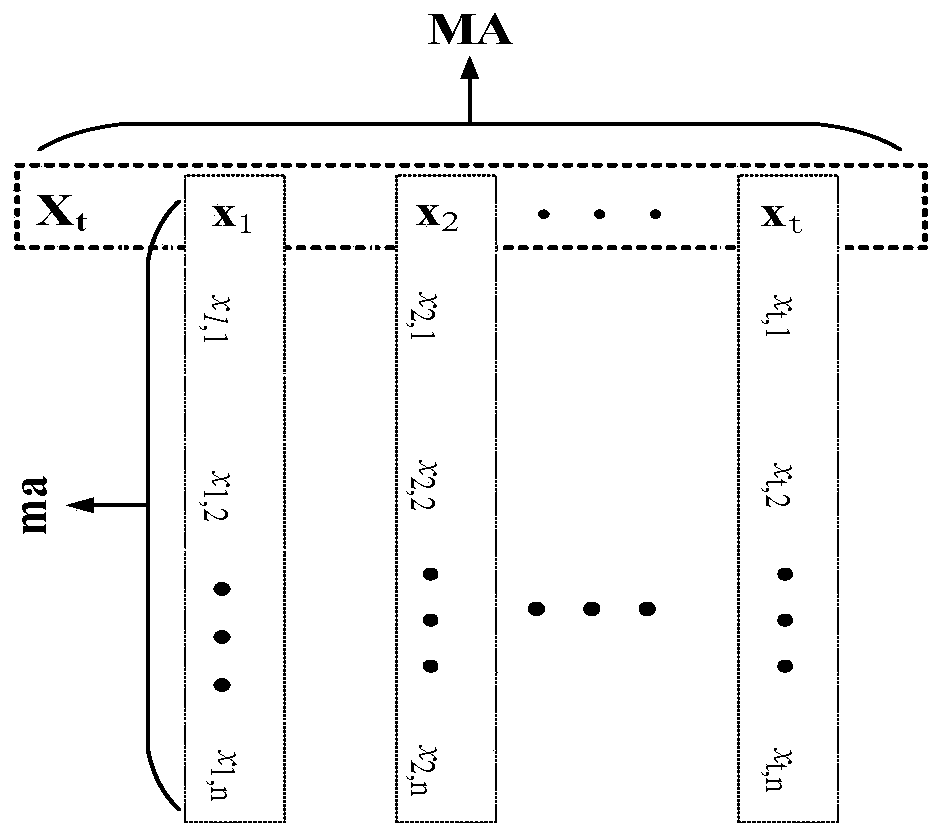

Method used

Image

Examples

Embodiment

[0079] According to the LTSMPP neural network model and prediction method proposed above, the experiment will be carried out below. In this experiment, the first-stage transmission is accelerated and the second-stage transmission is decelerated, so that the transmission ratio of the experimental gearbox is 1:1. The amount of lubricating oil in the experimental gearbox is 4L / h, and the cooling temperature is 70 degrees. Among them, the gear running platform is used; the torsion controller is used to control the torque applied to the gear in the test; the cooling and lubrication controller is used to control the cooling and lubrication of the gear in the experiment; the actual operation platform is used to operate the whole experiment switch and set some experimental parameters. The material used for the experimental gear is 40Cr, the machining accuracy is grade 5, the surface hardness is 55HRC, and the modulus is 5. In particular, the number of teeth of the large gear is 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com