White-light LED structure with extremely high barrier layer insertion layer

A technology of LED structure and insertion layer, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high production cost and complicated production process, and achieve the effect of reducing packaging process and reducing stability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

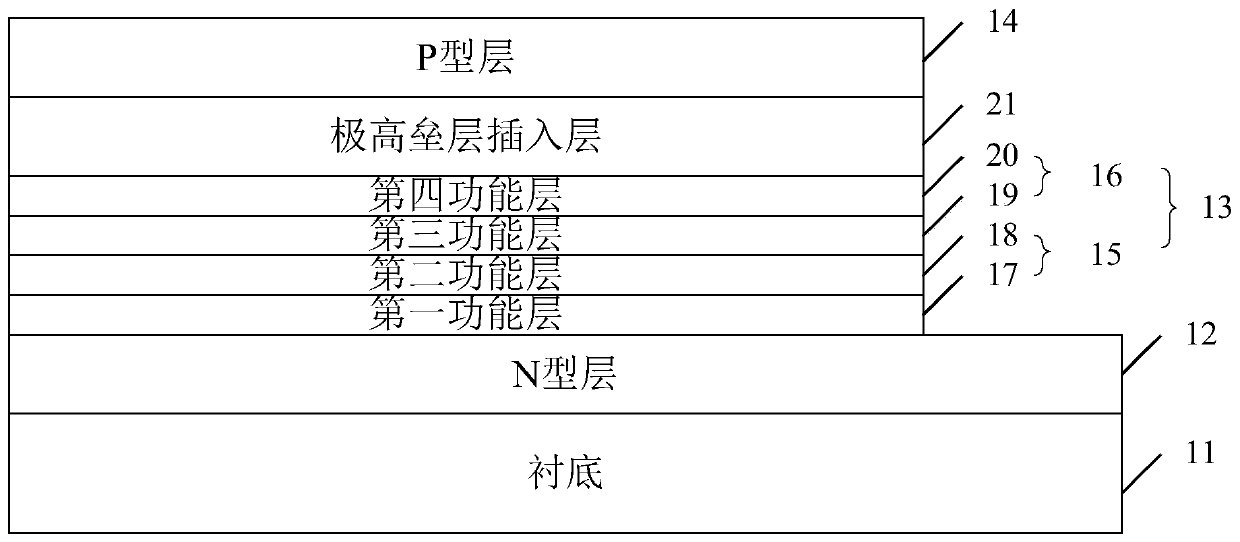

Embodiment 1

[0087] refer to figure 2 , figure 2 A schematic structural diagram of another white light LED structure with an extremely high barrier insertion layer provided by an embodiment of the present invention.

[0088] Step 1: Using equipment MOCVD, trimethylgallium TMGa, triethylgallium TEGa, ammonia NH 3 Ga source, N source, N 2 is the carrier gas, the N-type and P-type dopant sources are silane SiH respectively 4 and Magnesium CP 2 Mg, use InGaN ternary substrate, In composition is 0.1.

[0089] Step 2: Put the InGaN substrate 11 into the MOCVD reaction chamber, pass through TMGa, TMIn, SIH 4 , NH 3 N-type layer 12 is grown, and the concentration of Si is 6×10 18 / cm 3 , the In component is 0.1; the thickness is 0.5 μm.

[0090] Step 3: Introduce TEGa, TMIn, NH 3 The first functional layer 17 is grown with a thickness of 4 nm and an In composition of 0.35.

[0091] Step 4: Introduce TEGa, TMIn, NH 3 Grow the second functional layer 18, thickness 6nm, In composition 0...

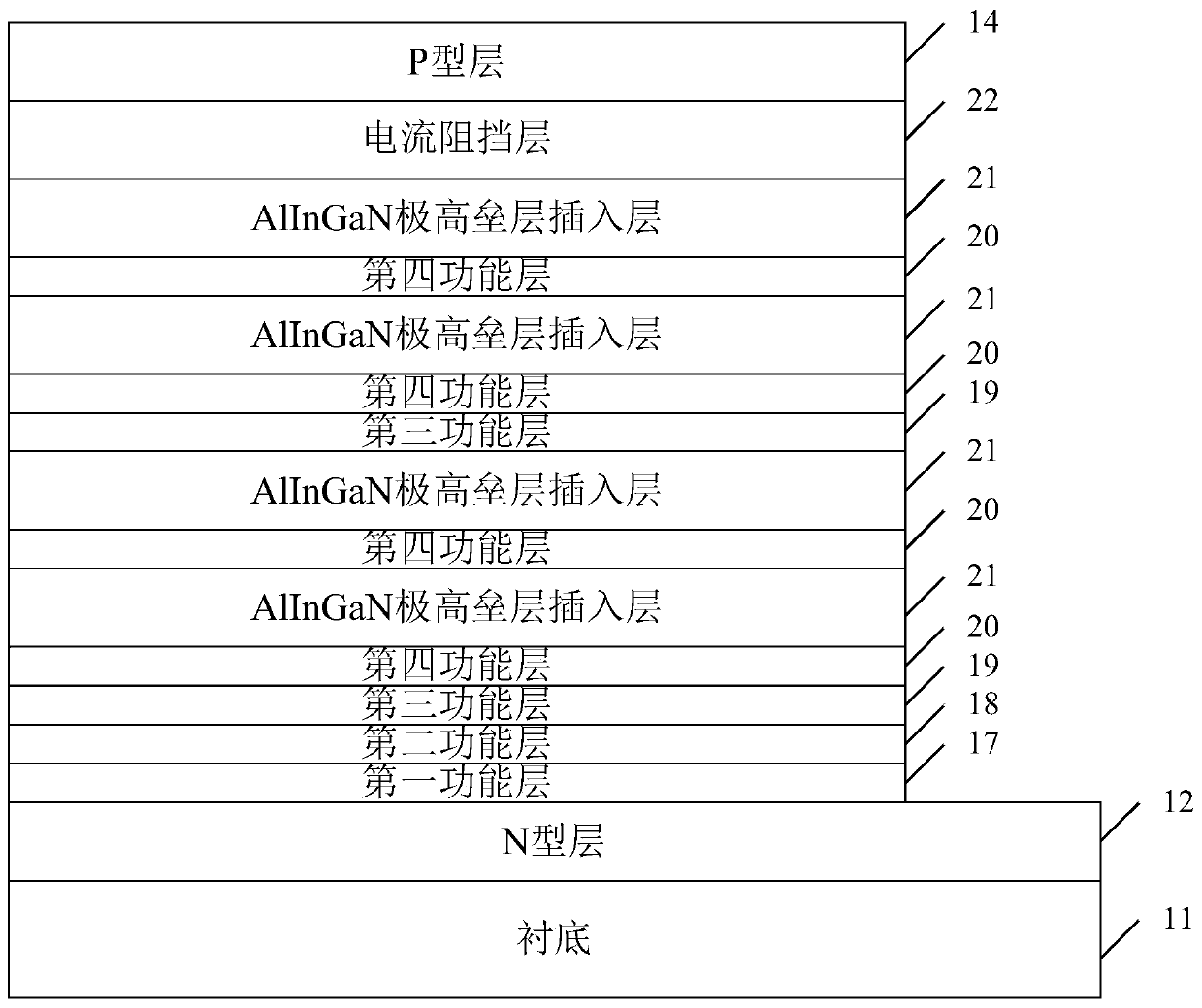

Embodiment 2

[0103] refer to image 3 , image 3 A schematic structural diagram of yet another white light LED structure with a very high barrier insertion layer provided by an embodiment of the present invention.

[0104] Step 1: Using equipment MOCVD, trimethylgallium TMGa, triethylgallium TEGa, ammonia NH 3 Ga source, N source, N 2 is the carrier gas, the N-type and P-type dopant sources are silane SiH respectively 4 and Magnesium CP 2 Mg, use InGaN ternary substrate, In composition is 0.1.

[0105] Step 2: Put the InGaN substrate 11 into the MOCVD reaction chamber, and feed TMGa, TMIn, SIH4, NH 3 N-type layer 12 is grown, and the concentration of Si is 6×10 18 / cm 3 , the In component is 0.1; the thickness is 0.5 μm.

[0106] Step 3: Introduce TEGa, TMIn, NH 3 The first functional layer 17 is grown with a thickness of 4 nm and an In composition of 0.35.

[0107] Step 4: Introduce TEGa, TMIn, NH 3 Grow the second functional layer 18, thickness 6nm, In composition 0.1, SiH 4 ...

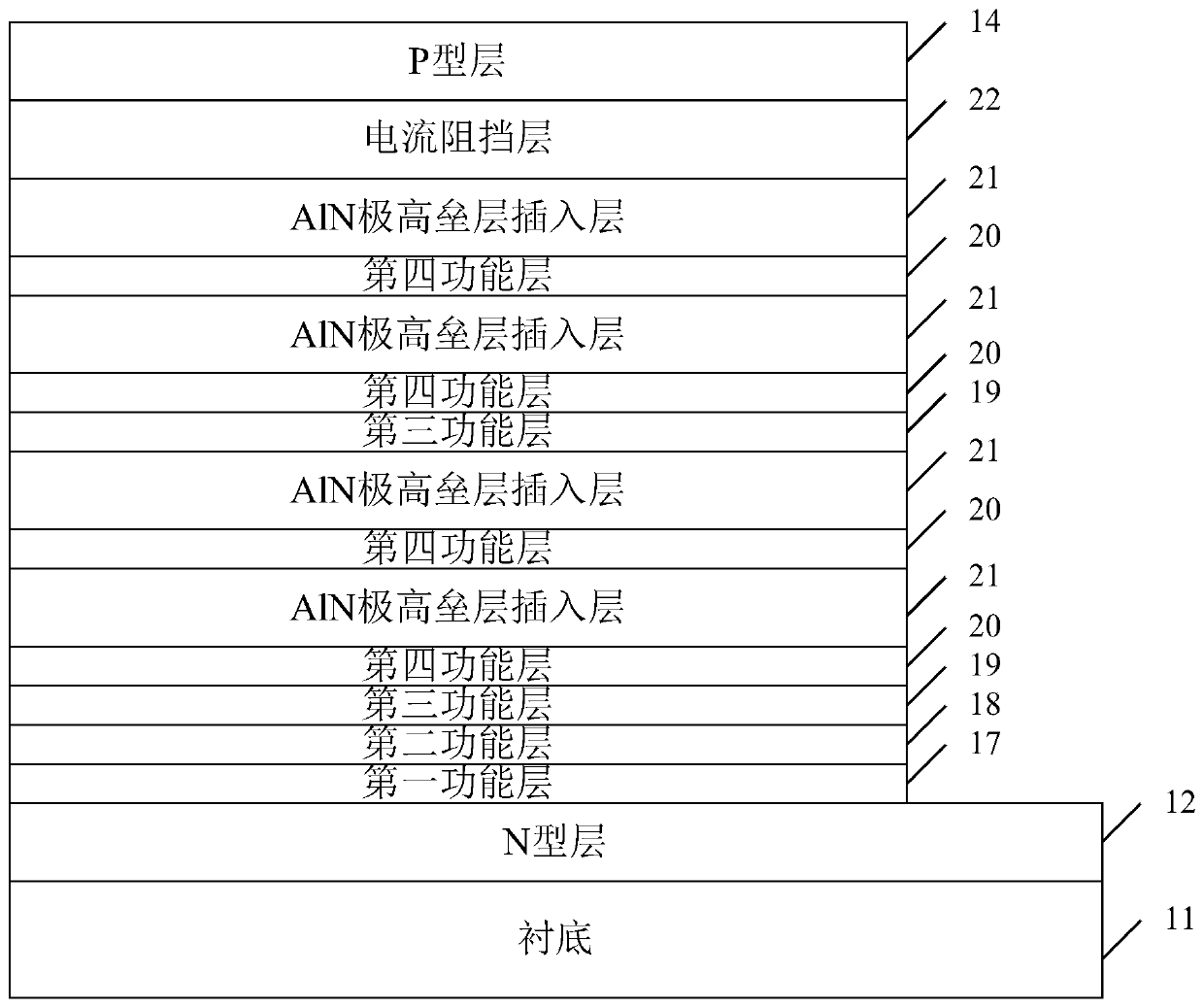

Embodiment 3

[0120] refer to Figure 4 , Figure 4 A schematic structural diagram of yet another white light LED structure with a very high barrier insertion layer provided by an embodiment of the present invention.

[0121] Step 1: Using equipment MOCVD, trimethylgallium TMGa, triethylgallium TEGa, ammonia NH 3 Ga source, N source, N 2 is the carrier gas, the N-type and P-type dopant sources are silane SiH respectively 4 and Magnesium CP 2 Mg, use InGaN ternary substrate, In composition is 0.1.

[0122] Step 2: Put the InGaN substrate 11 into the MOCVD reaction chamber, pass through TMGa, TMIn, SIH 4 , NH 3 N-type layer 12 is grown, and the concentration of Si is 6×10 18 / cm 3 , the In component is 0.1; the thickness is 0.5 μm.

[0123] Step 3: Introduce TEGa, TMIn, NH 3 The first functional layer 17 is grown with a thickness of 4 nm and an In composition of 0.35.

[0124] Step 4: Introduce TEGa, TMIn, NH 3 Grow the second functional layer 18, thickness 6nm, In composition 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com