Processing method capable of reducing bitter taste of summer red broken tea

A processing method and a technology of bitterness and astringency, which are applied in the processing field of reducing the bitterness and astringency of red crushed tea in summer. It can solve the problems of heavy bitterness, weak aroma, and dry color of the finished product, so as to enhance the aroma of its own tea, reduce the bitterness and astringency, and balance the fermentation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

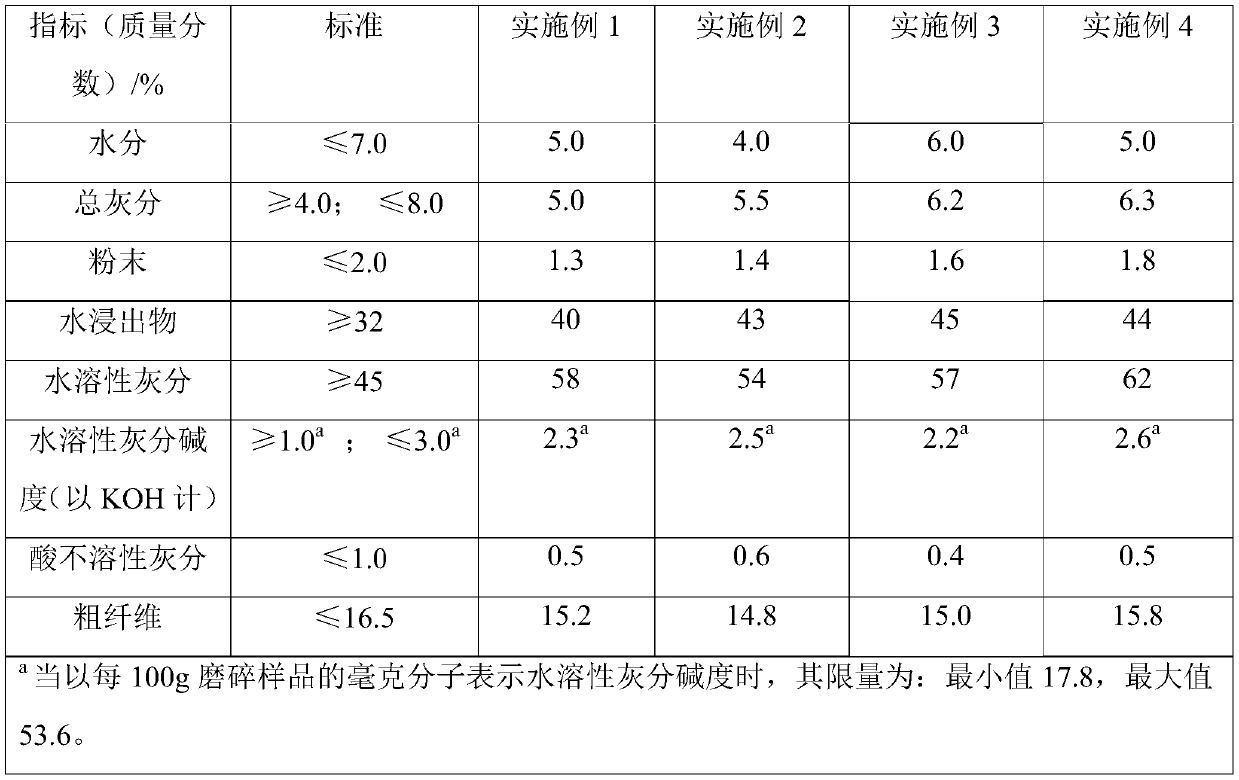

Embodiment 1

[0036] A processing method for reducing the bitterness and astringency of summer red crushed tea, comprising the following steps:

[0037] (1) Picking fresh leaves of tea trees: Picking 4-5 leaves of a bud of Jinxuan, Cuiyu, Huangjingui, Fuding Dahao tea and Fuyun No. 6 tea trees and mixing them with summer fresh leaves of the same tenderness Raw materials, the picked fresh leaves are required to be fresh and free from other non-tea inclusions;

[0038] (2) Sunshine: spread the picked fresh leaves evenly on the sunbathing cloth, the thickness of the sunbaked leaves is 2-3cm, sunbathe for 22 minutes, turn over once during the sunbathing process, and the water loss rate of sunbaked fresh leaves is controlled at 5 %, to obtain sun-dried green leaves, the fresh leaves lose their luster after sun-dried, and the leaf color changes from bright green to dark green;

[0039] (3) Light withering: Put the sun-dried green leaves into the withering tank for light withering, the thickness ...

Embodiment 2

[0045] A processing method for reducing the bitterness and astringency of summer red crushed tea, comprising the following steps:

[0046] (1) Picking fresh leaves of tea trees: Picking 4-5 leaves of a bud of Jinxuan, Cuiyu, Huangjingui, Fuding Dahao tea and Fuyun No. 6 tea trees and mixing them with summer fresh leaves of the same tenderness Raw materials, the picked fresh leaves are required to be fresh and free from other non-tea inclusions;

[0047] (2) Sunshine: spread the picked fresh leaves evenly on the sunbathing cloth, the thickness of the sunbaked leaves is 2-3cm, sunbathe for 23min, flip once during the sunbathing process, the water loss rate of sunbaked fresh leaves is controlled at 5 %, to obtain sun-dried green leaves, the fresh leaves lose their luster after sun-dried, and the leaf color changes from bright green to dark green;

[0048] (3) Light withering: Put the sun-dried green leaves into the withering tank for light withering, the thickness of the leaves ...

Embodiment 3

[0054] A processing method for reducing the bitterness and astringency of summer red crushed tea, comprising the following steps:

[0055] (1) Picking fresh leaves of tea trees: Picking 4-5 leaves of a bud of Jinxuan, Cuiyu, Huangjingui, Fuding Dahao tea and Fuyun No. 6 tea trees and mixing them with summer fresh leaves of the same tenderness Raw materials, the picked fresh leaves are required to be fresh and free from other non-tea inclusions;

[0056] (2) Sunshine: spread the picked fresh leaves evenly and thinly on the sunbathing cloth, the thickness of the sunbaked leaves is 2-3cm, sunbathe for 20 minutes, flip once during the sunbathing process, the water loss rate of sunbaked fresh leaves is controlled at 4 %, to obtain sun-dried green leaves, the fresh leaves lose their luster after sun-dried, and the leaf color changes from bright green to dark green;

[0057] (3) Light withering: put the sun-dried green leaves into the withering tank for light withering, the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com