Method and equipment for rapid pretreatment of kitchen waste

A food waste and pretreatment technology, which is applied in the fields of solid waste removal, climate change adaptation, organic fertilizer, etc., can solve the problems of low utilization rate of solid products and poor treatment effect of food waste, and improve solid-liquid separation Effects of Efficiency, Stability and Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

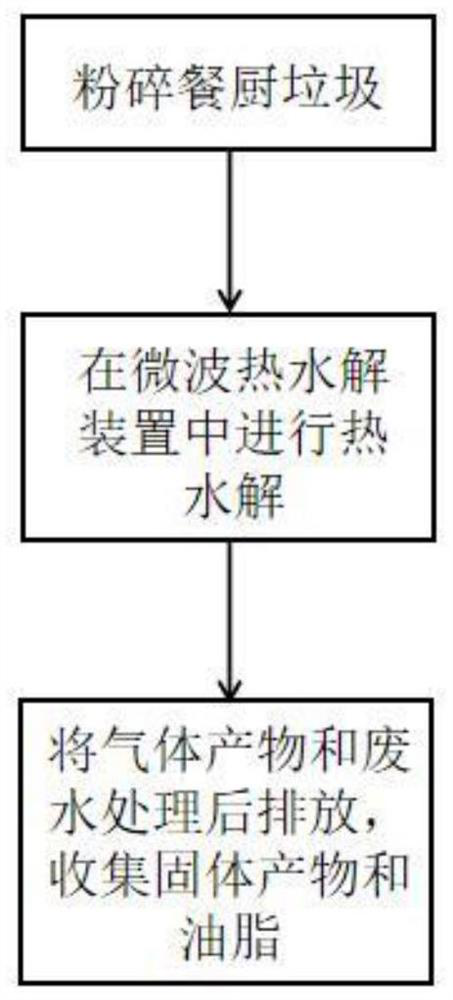

[0047] (a) Adding water to rice kitchen waste and pulverizing it into a microwave thermal hydrolysis device;

[0048] (b) The pulverized meal kitchen waste is subjected to a thermal hydrolysis reaction in a microwave thermal hydrolysis device, the reaction temperature is set at 140° C., and the reaction time is 55 minutes;

[0049] (c) After the reaction is completed, the gas product is purified and discharged, and then the solid-liquid product is separated step by step to obtain solid product, oil and waste water, the solid product and oil are collected, the solid product is used for anaerobic digestion, and the waste water is treated rear discharge.

Embodiment 2

[0051] (a) Adding water to the mixed kitchen waste and pulverizing it into a microwave thermal hydrolysis device;

[0052] (b) The pulverized mixed kitchen waste is subjected to a thermal hydrolysis reaction in a microwave thermal hydrolysis device, the reaction temperature is set at 160°C, and the reaction time is 80 minutes;

[0053] (c) After the reaction is completed, the gas product is purified and discharged, and then the solid-liquid product is separated step by step to obtain solid product, oil and waste water, the solid product and oil are collected, the solid product is used for anaerobic digestion, and the waste water is treated rear discharge.

Embodiment 3

[0055] (a) adding water to the meat kitchen waste and pulverizing it into a microwave thermal hydrolysis device;

[0056] (b) The crushed meat kitchen waste is subjected to thermal hydrolysis reaction in a microwave thermal hydrolysis device, the reaction temperature is set to 180°C, and the reaction time is 40 minutes;

[0057] (c) After the reaction is completed, the gas product is purified and discharged, and then the solid-liquid product is separated step by step to obtain solid product, oil and waste water, the solid product and oil are collected, the solid product is used for anaerobic digestion, and the waste water is treated rear discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com