Catalytic body for municipal activated sludge treatment, sludge treatment system and sludge treatment method

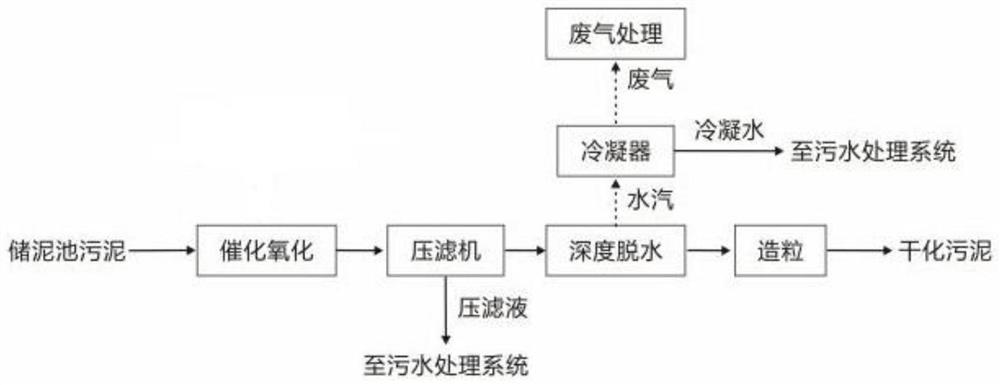

An activated sludge and treatment system technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve low gas production, high water content, slow hydrolysis process rate And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

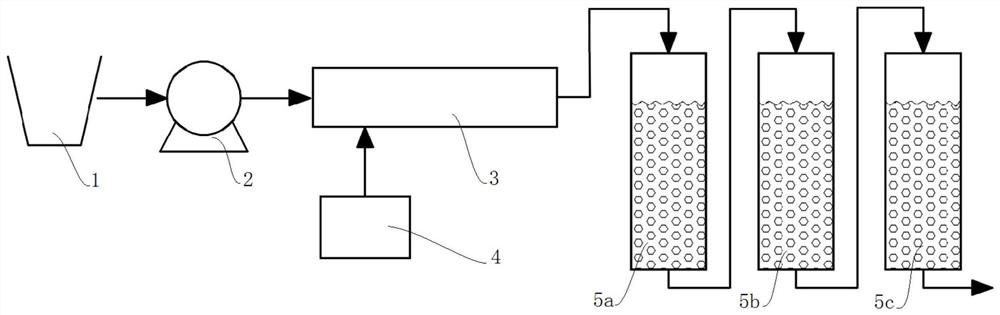

Method used

Image

Examples

Embodiment

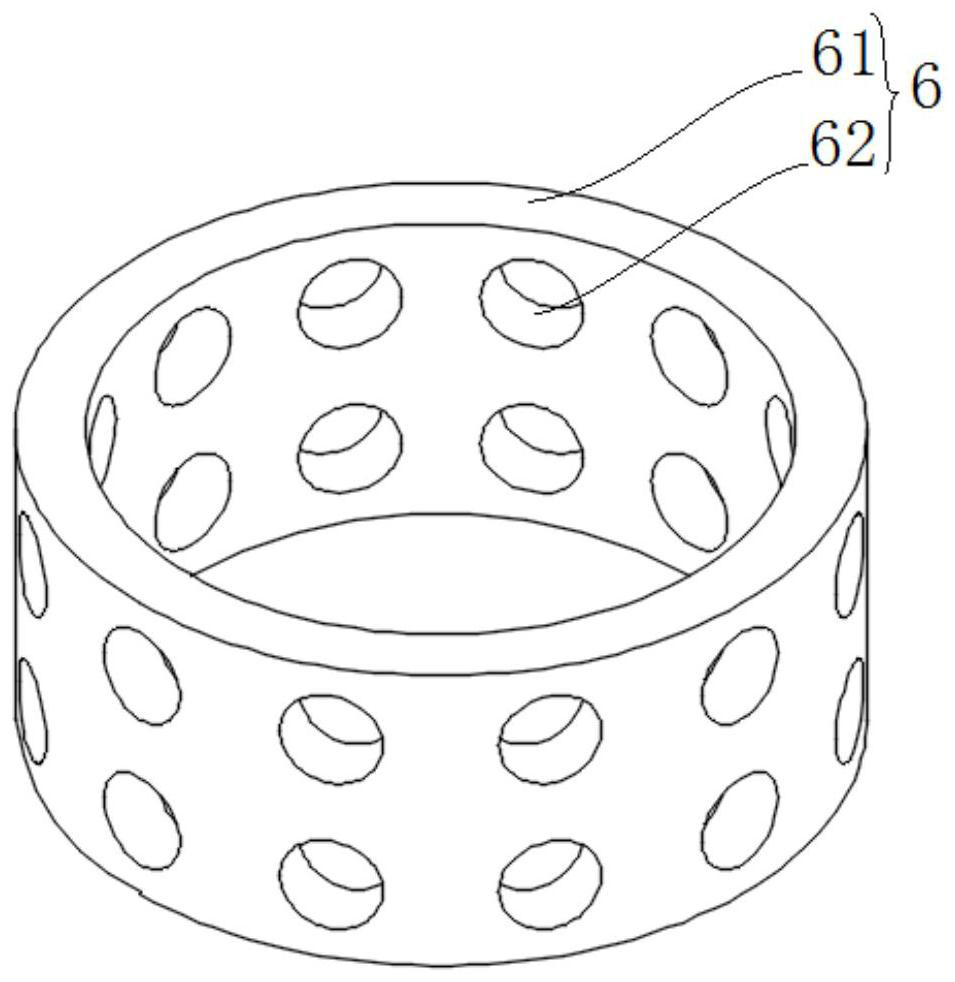

[0044] refer to image 3 As shown, the municipal activated sludge treatment catalytic body, the catalytic body 6 is a carrier made of stainless steel, the surface of the stainless steel material is preferably but not limited to a metal layer of platinum oxide, and rhodium oxide, palladium oxide, iridium oxide, etc. precious metal oxides. Platinum is solidified on the surface of the stainless steel material by sintering or sputtering. The stainless steel material structure is preferably a circular tube body 61, a plurality of through holes 62 are provided on the tube wall of the tube body 61, the diameter of the tube body 61 is 30mm, the wall thickness of the tube body is 1.5mm, and the length of the tube body is 25mm. The diameter of the through hole is 5mm. The diameter, wall thickness, and length of the pipe body 61 are determined by the catalytic body 6 being able to enter the reactor under the impact force of the mixture in the reactor, and the mixture forms a continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com