Construction waste soil improver prepared from kitchen waste, preparation method of improved construction waste soil and application of improved construction waste soil improver

A technology for kitchen waste and construction slag, which is applied in the field of construction slag resource recycling, can solve the problems of poor soil water and fertilizer retention, frequent soil fertilization, etc., and achieves high water stability, shortened curing time, and guaranteed activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

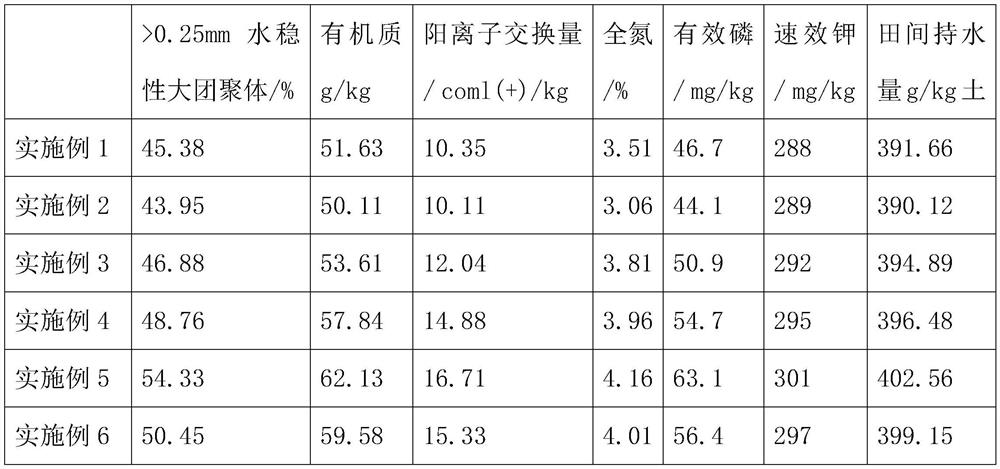

Examples

preparation example 1

[0043] The construction slag improvement agent prepared by using kitchen waste includes the following raw materials: 1 kg of improved kitchen waste, microbial agent consisting of 4 g of actinomycetes and 6 g of Bacillus subtilis, and 10 g of sodium polyacrylate with a molecular weight of 20 million , urea 10g, oyster powder 200g, kaolin 50g;

[0044] The improved kitchen waste is prepared through the following preparation steps: the kitchen waste is sieved to remove impurities, and then the kitchen waste is sent into a high-pressure extruder for deoiling and desalination pretreatment under an extrusion pressure of 20 MPa , and then add BGB composite bacteria agent to the pretreated kitchen waste to ferment the kitchen waste, the amount of BGB composite bacteria added is 1% of the mass of the pretreated kitchen waste, the fermentation temperature is 70°C, and the time For 20h, improved kitchen waste was obtained; wherein the water content of kitchen waste was 74.94%, crude prot...

preparation example 2

[0046] The construction dregs improvement agent prepared by using kitchen wastes includes the following raw materials: 1.5 kg of improved kitchen wastes, the microbial agent consists of 18 g of Paenibacillus jelly-like, 7 g of Bacillus licheniformis and 13 g of Bacillus megaterium, 20g of sodium polyacrylate with a molecular weight of 15 million, 20g of urea, 100g of oyster powder, and 100g of montmorillonite;

[0047] The rest are the same as in Preparation Example 1.

preparation example 3

[0049] The construction slag improvement agent prepared by using kitchen waste includes the following raw material components: 1.2kg of improved kitchen waste, the microbial agent is composed of 12g of Bacillus subtilis, 15g of Paenibacillus jelly-like and 11g of Bacillus licheniformis, Sodium polyacrylate 15g, urea 12g, oyster powder 180g, kaolin 88g;

[0050] The rest are the same as in Preparation Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com