Method for preparing organic mineral fertilizer from oil shale semicoke

A technology of oil shale semi-coke and organic mineral fertilizers, which is applied in the field of waste resource reuse, can solve the problems that plants cannot be fully and effectively utilized, and do not have activity, etc., and achieve the goal of realizing resource utilization, improving nutritional levels, and improving crop quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

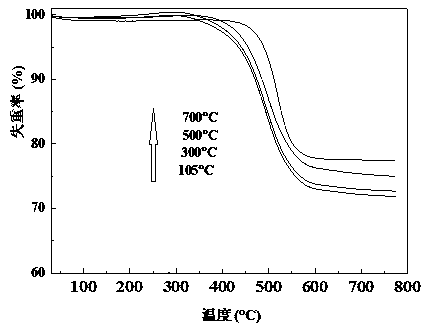

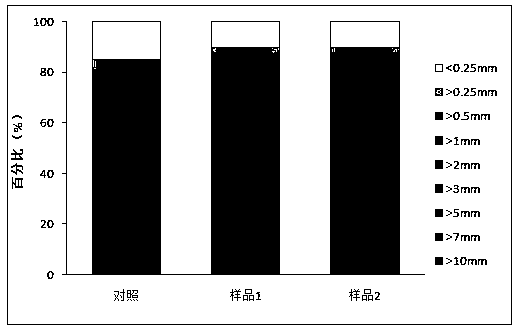

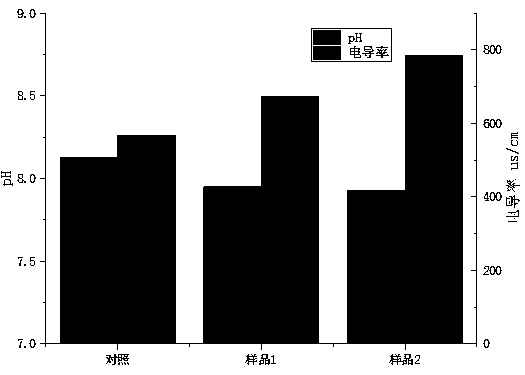

[0021] The oil shale semi-coke is crushed to 80 mesh, added to the phosphoric acid solution with a mass concentration of 8% for 3 hours, and then dehydrated to 40% with a plate and frame filter press, and then sent to the rotary kiln with twin screws. Calcined at 300°C for 3 hours under a nitrogen atmosphere, then treated with 5% potassium hydroxide solution for 1 hour, and then added the composite bacteria solution (wherein, the composite bacteria consisted of Bacillus subtilis, Bacillus licheniformis, yeast and Pseudomonas composite bacteria by 1 : 1:1:1 mass ratio composite, the composite bacteria solution is prepared by mixing water and composite bacteria at a weight ratio of 130:1; the mass ratio of oil shale semi-coke to composite bacteria solution is 8:1) and mix evenly, Cultivate at 30° C. for 12 hours, dry and granulate to obtain an organic mineral fertilizer product. The XRF composition analysis of organic and mineral fertilizers is shown in Table 1. The product con...

Embodiment 2

[0023] The oil shale semi-coke is crushed to 80 mesh, added to a sulfuric acid solution with a mass concentration of 6% for activation treatment for 2 hours, and then dehydrated to 40% with a plate and frame filter press, and then sent into a rotary kiln with twin screws. Calcined at 350°C for 3 hours under a nitrogen atmosphere, then treated with 3% sodium hydroxide solution for 1 hour, and then added the composite bacteria solution (wherein, the composite bacteria consisted of Bacillus subtilis, Bacillus licheniformis, nitrifying bacteria and Pseudomonas composite bacteria according to 1:1:1 mass ratio composite, the composite bacteria solution is prepared by mixing water and composite bacteria at a weight ratio of 120:1; the mass ratio of oil shale semi-coke to composite bacteria solution is 8:1) and mix evenly, in Cultivate at 28°C for 14 hours, dry and granulate to obtain an organic mineral fertilizer product. The resulting product contains 23.64% organic matter, SiO 2 5...

Embodiment 3

[0025] Oil shale semi-coke was crushed to 80 mesh, added to a phosphoric acid solution with a mass concentration of 6% for activation treatment for 3 hours, dehydrated to 40% by pressure filtration with a plate and frame filter press, and then sent into a rotary kiln with twin-screws. Calcined at 450°C for 1.5h in the atmosphere, then treated with 3% potassium hydroxide solution for 2h, and then added the complex bacteria solution (wherein, the complex bacteria were composed of Bacillus licheniformis, nitrifying bacteria and pseudomonas complex bacteria in a ratio of 1:1:1 The mass ratio compound, the composite bacteria solution is prepared by mixing water and the composite bacteria at a weight ratio of 150:1; the mass ratio of oil shale semi-coke to the composite bacteria solution is 6:1), mix evenly, and cultivate at 35°C for 16 hours, Dried and granulated to obtain organic mineral fertilizer products. The XRF composition analysis of organic and mineral fertilizers is shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com