A kind of chromatographic purification method of Quina bark alcohol

A technology for the purification of quebranol and its purification method, which is applied in the field of extraction and separation of natural products, can solve the problems of complicated purification process operation, difficult industrial production, and low output of quebranol, and achieve the effect of overcoming the low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

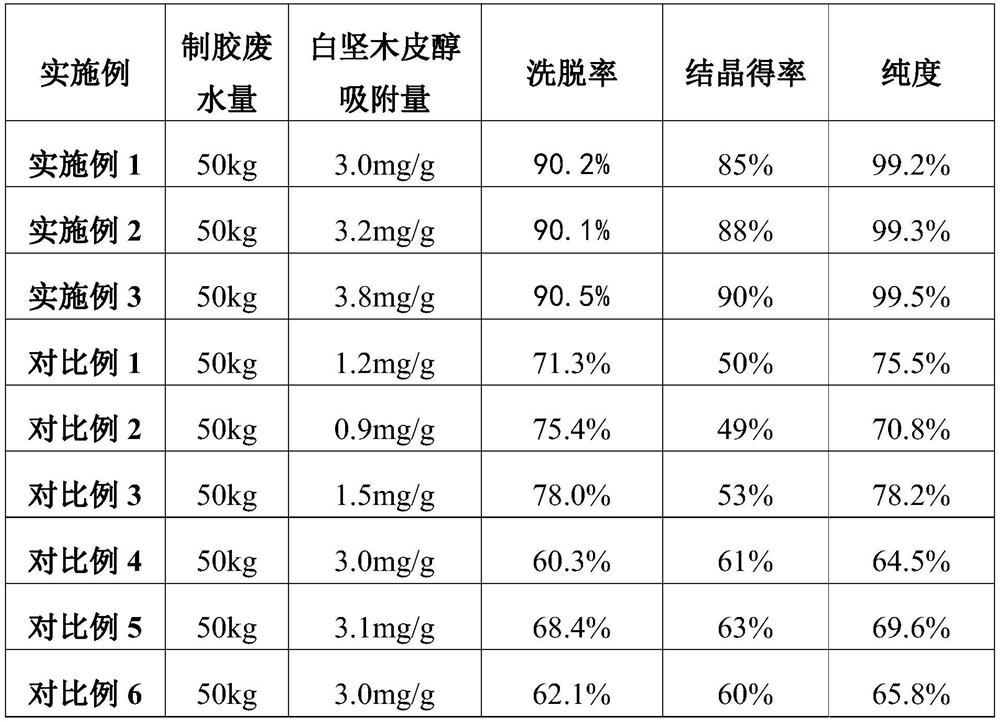

Examples

Embodiment 1

[0030] Embodiment 1-a kind of chromatographic purification method of Quina bark alcohol, comprises the steps:

[0031] (1) Pretreatment of rubber wastewater

[0032] Heat the gel-making waste water to 90°C, add calcium oxide, filter to remove floating glue, flocs and solid impurities, and obtain the initial liquid; evaporate and concentrate the filtrate to 1 / 3 of the original volume to obtain the concentrated initial liquid;

[0033] (2) Activated carbon decolorization

[0034] Cool and filter the concentrated initial solution, pass the filtrate through a chromatographic column equipped with powdered activated carbon, elute with 3 times the column volume of deionized water, and collect the effluent from the activated carbon column;

[0035] (3) Macroporous resin adsorption

[0036] Weigh the polar resins HPD400, HPD600 and D145 with a mass ratio of 3:2:1 and place them in a stoppered Erlenmeyer flask, add activated carbon column effluent, wherein the polar resins HPD400, HPD...

Embodiment 2

[0041] Embodiment 2-a kind of chromatographic purification method of Quina cortex alcohol, comprises the steps:

[0042] (1) Pretreatment of rubber wastewater

[0043] Heat the gel-making waste water to 100°C, add calcium oxide, filter to remove floating glue, flocs and solid impurities, and obtain the initial liquid; evaporate and concentrate the filtrate to 1 / 6 of the original volume to obtain the concentrated initial liquid;

[0044] (2) Activated carbon decolorization

[0045] Cool and filter the concentrated initial solution, pass the filtrate through a chromatographic column equipped with powdered activated carbon, elute with 4 times the column volume of deionized water, and collect the effluent from the activated carbon column;

[0046] (3) Macroporous resin adsorption

[0047]Weighing polar resins HPD400, HPD600 and D145 with a mass ratio of 3:3:1 were placed in a stoppered Erlenmeyer flask, and the activated carbon column effluent was added, wherein the total mass o...

Embodiment 3

[0052] Embodiment 3-a kind of chromatographic purification method of Quina cortex alcohol, comprises the steps:

[0053] (1) Pretreatment of rubber wastewater

[0054] Heat the gel-making waste water to 100°C, add calcium oxide, filter to remove floating glue, flocs and solid impurities, and obtain the initial liquid; evaporate and concentrate the filtrate to 1 / 5 of the original volume to obtain the concentrated initial liquid;

[0055] (2) Activated carbon decolorization

[0056] Cool and filter the concentrated initial solution, pass the filtrate through a chromatographic column equipped with powdered activated carbon, elute with 3 times the column volume of deionized water, and collect the effluent from the activated carbon column;

[0057] (3) Macroporous resin adsorption

[0058] The polar resins HPD400, HPD600 and D145 with a mass ratio of 2:2:1 were weighed respectively and placed in a stoppered Erlenmeyer flask, and the activated carbon column effluent was added, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com