Separating type underwater wellhead suction force anchor in efficient machining and transporting

An underwater wellhead and suction anchor technology, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of oil and gas resource leakage in the formation, the large size of the suction anchor structure, and the inability to produce tightness, etc. To achieve the effect of improving the bearing capacity of the wellhead, reducing the production cost and transportation cost, and reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

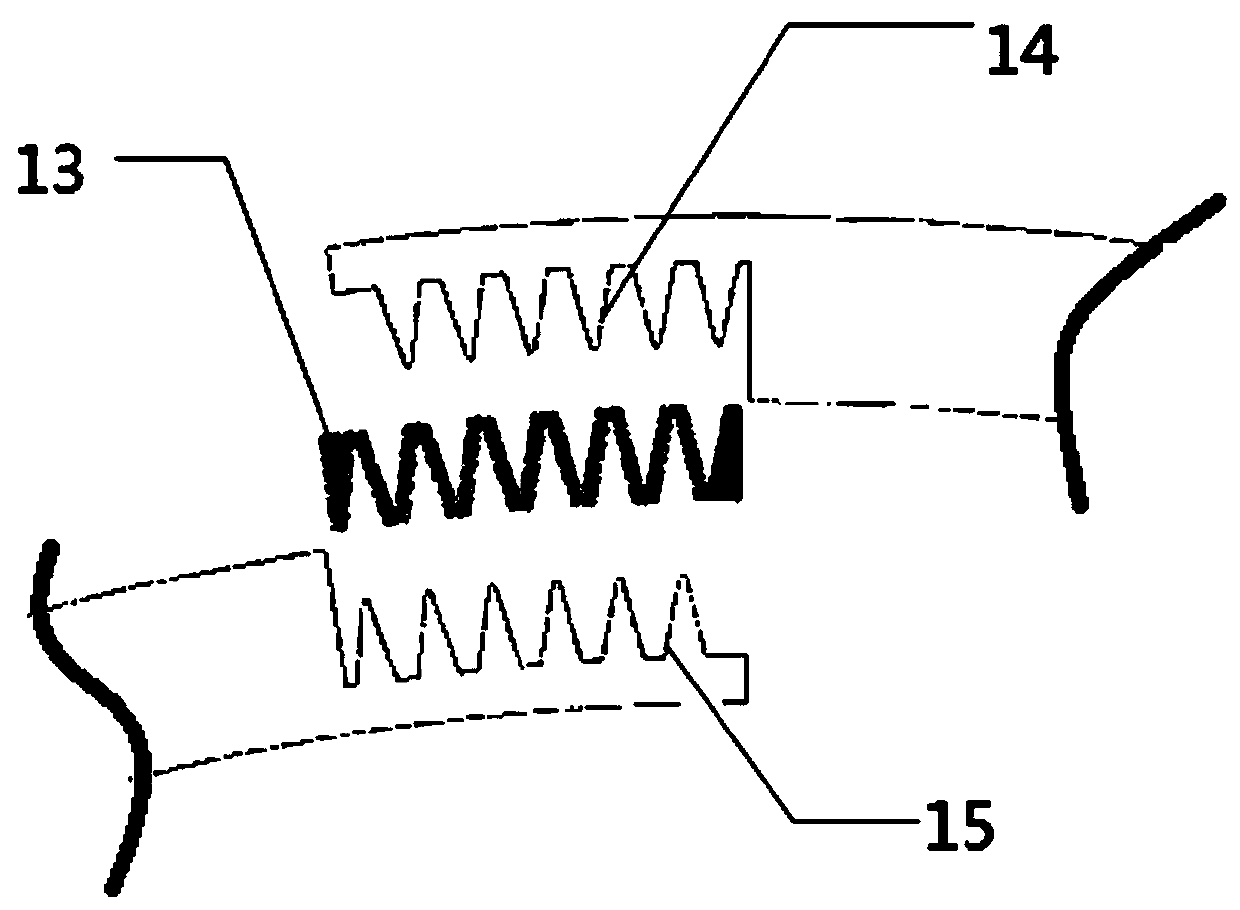

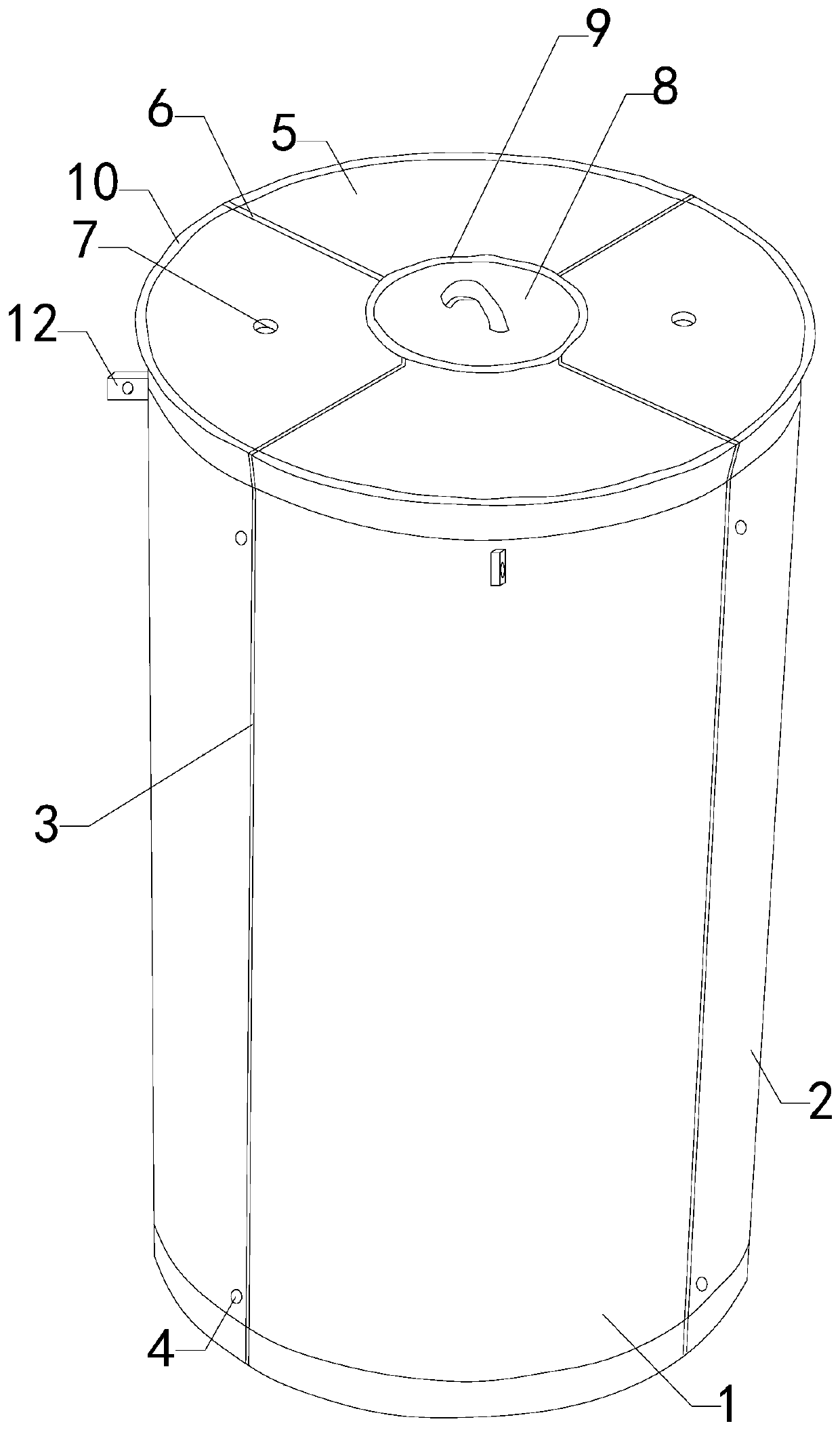

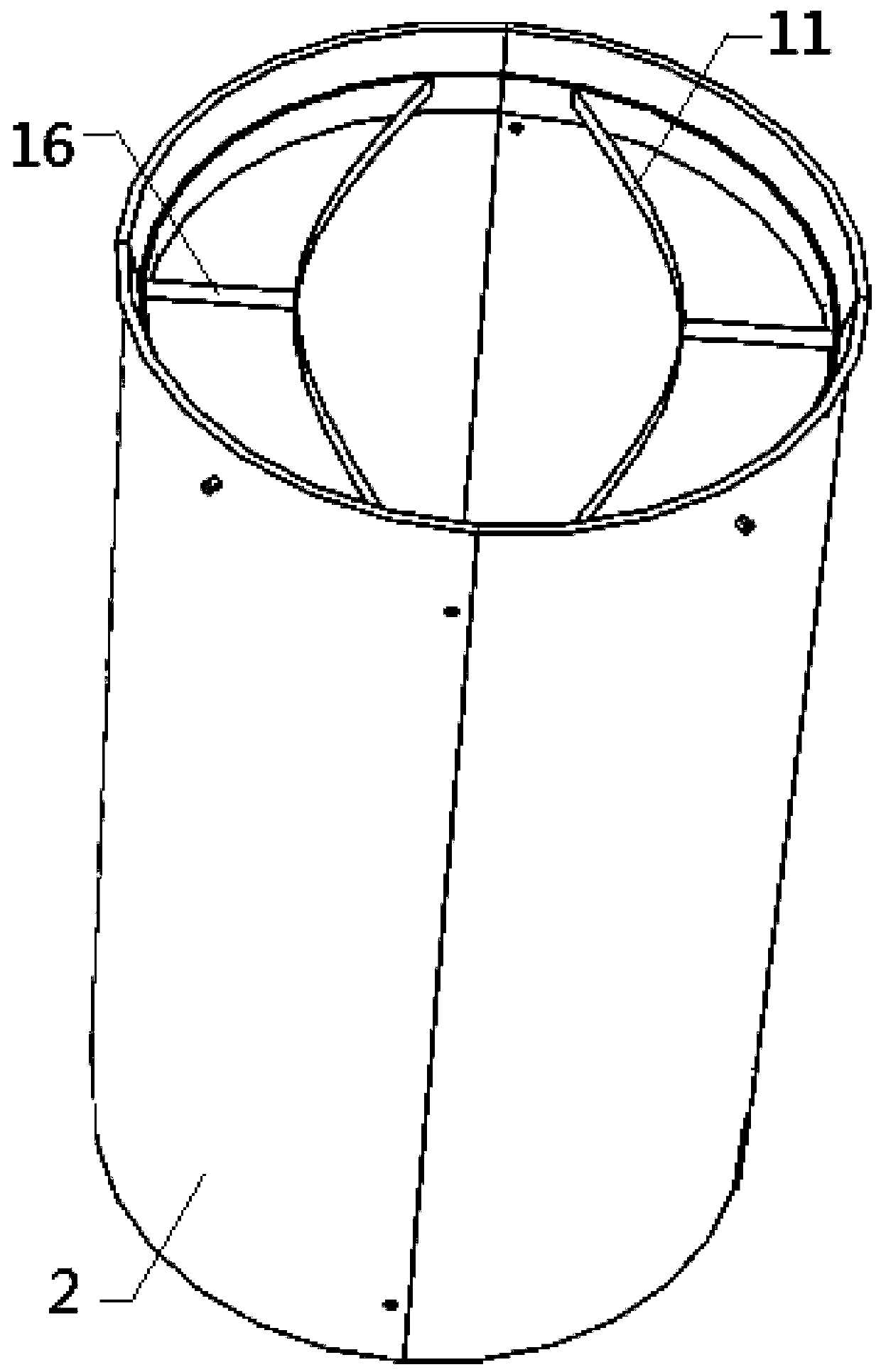

[0030] A separate underwater wellhead suction anchor for high-efficiency processing and transportation of the present invention includes a suction anchor cylinder body 1 with a lower end opening and a top seal. Multiple sets of first rubber strips 3 are used to seal the shells 2 of the anchor shells, and the positioning bolts 4 are used to connect each set of shells 2 of the anchor shells. The top of the shell 1 of the suction anchor is provided with 5 sets of separate sealing covers, and the shells of the anchor shells are The number of the 2 groups is the same as that of the 5 groups of separated sealing covers, and multiple sets of second sealing strips 6 are used to se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com