Automatic chip removing method and anti-settling collecting and conveying device for intelligent unmanned grinding and milling process

A milling and processing technology, applied in the field of automatic chip removal and anti-sedimentation collection and conveying device of intelligent unmanned milling process, can solve the problems of unmanned chemical plant shutdown loss, separation, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to achieve the technical means of the above-mentioned purpose of the present invention, an embodiment is exemplified hereby, and described in conjunction with the drawings as follows, so as to obtain a better understanding of the structure, characteristics, methods and achieved effects of the present invention.

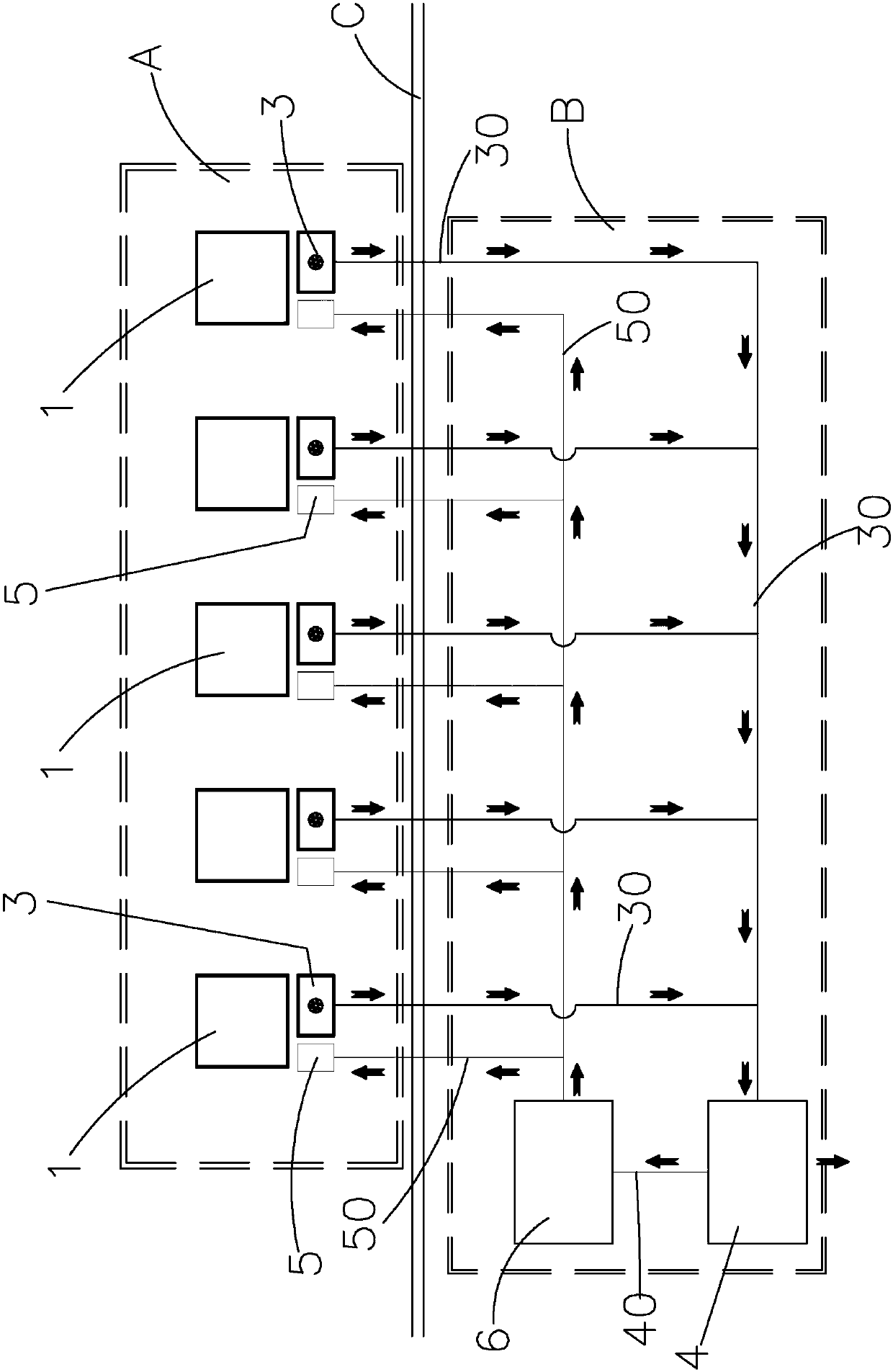

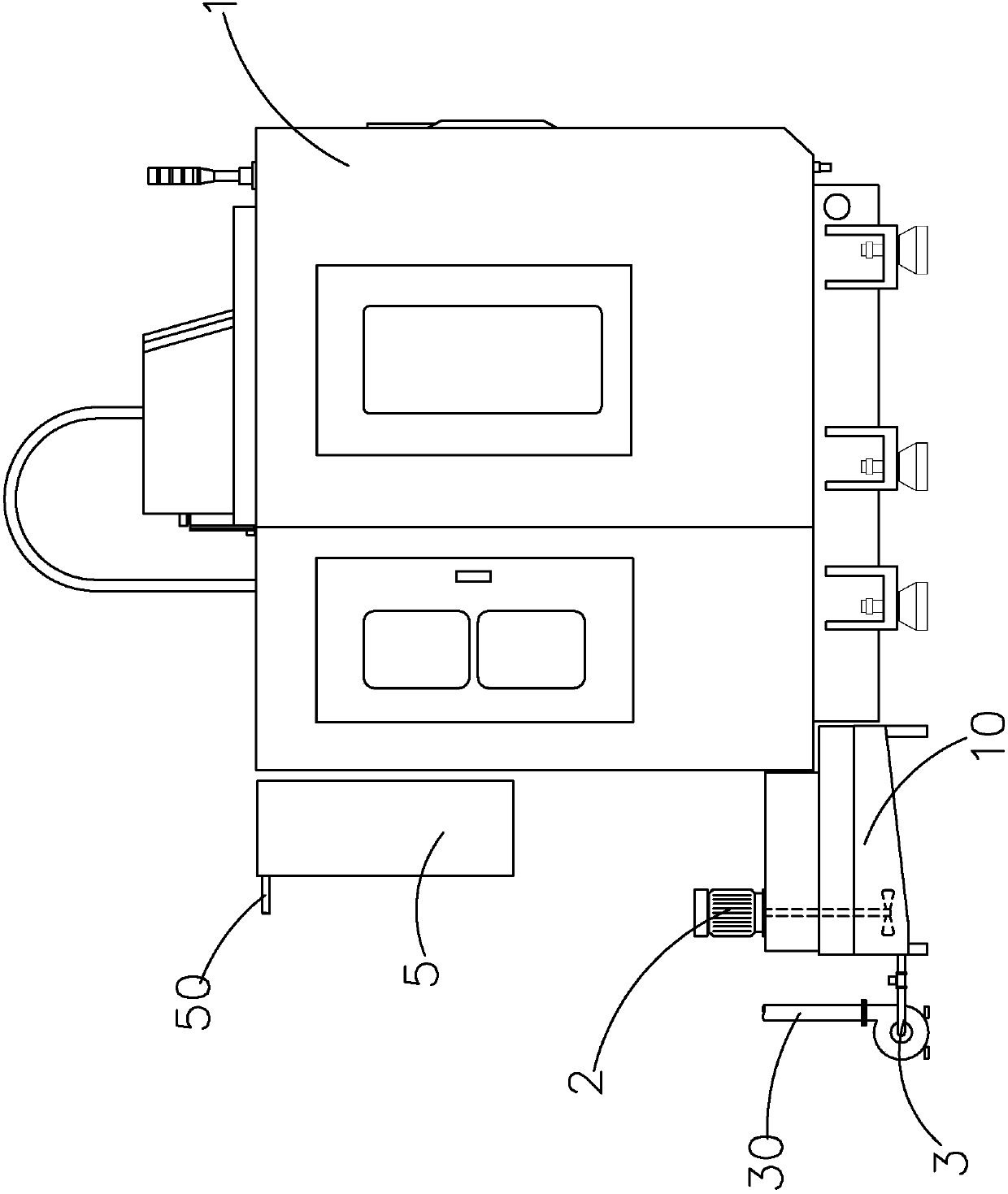

[0017] The present invention relates to an automatic chip removal method for an intelligent unmanned milling process, which is suitable for the wet milling process of non-metallic materials such as ceramics, glass or graphite in intelligent unmanned chemical factories. Please refer to figure 1 and figure 2 As shown, the method is: divide the unmanned operation factory area A and the outer operation area B by the partition wall C of the unmanned operation factory area, and each grinding and milling processing equipment 1 settling tank 10 set in the unmanned operation factory area A Stirring device 2 is provided, settling tank 10 is provided with convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com