Recycled concrete and preparation method thereof

A technology of recycled concrete and recycled coarse aggregate, applied in the field of building materials, can solve the problems of surface water loss, reduced strength performance of recycled concrete, aggravated micro-crack cracking degree, etc. The effect of adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

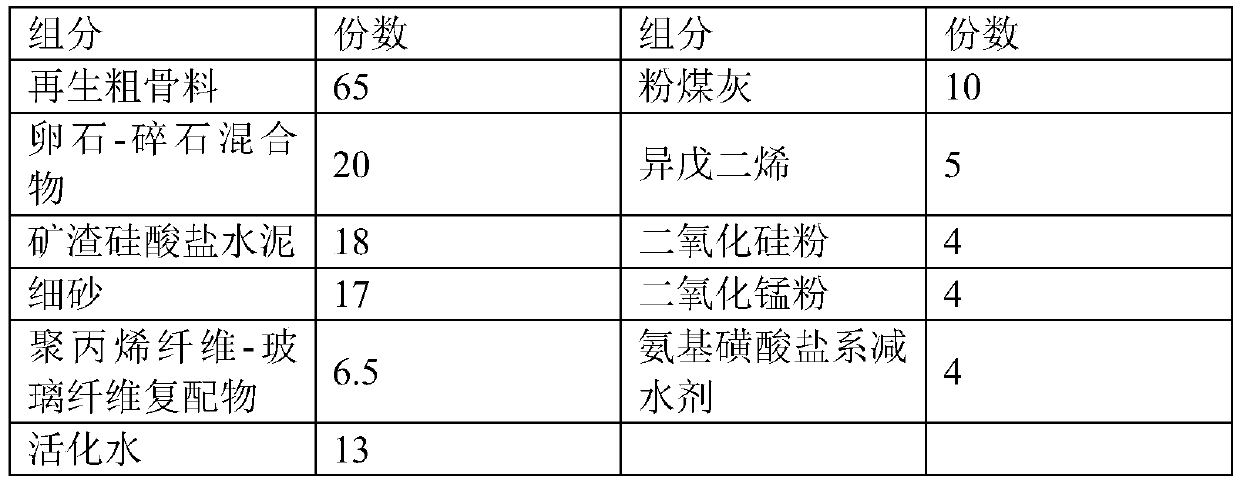

[0031] Embodiment 1 is a kind of recycled concrete disclosed by the present invention and its preparation method. The recycled concrete includes the following components by weight:

[0032]

[0033] The mass ratio of pebble-crushed stone mixture is 1:2.5; the polypropylene fiber-glass fiber compound is put into use after surface treatment with argon plasma;

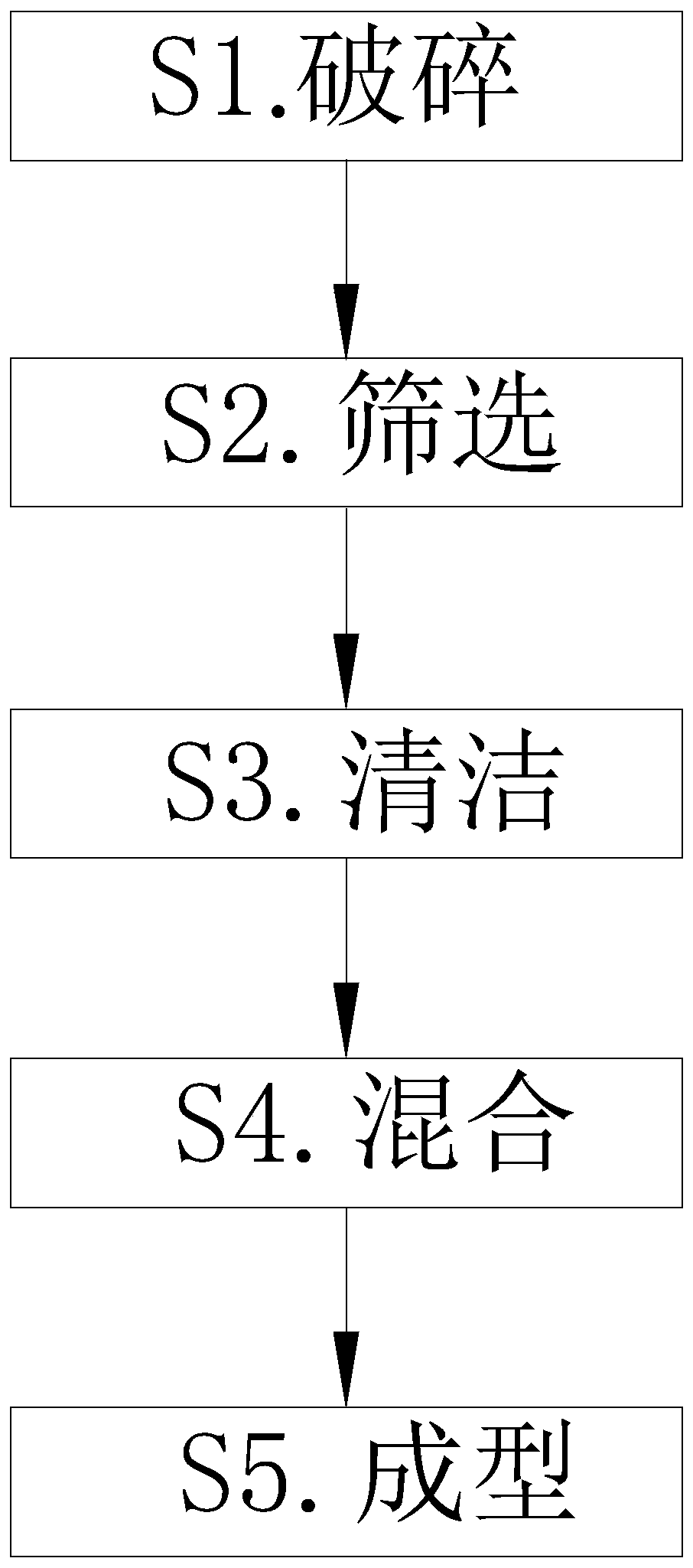

[0034] The preparation method of recycled concrete specifically comprises the following steps:

[0035] S1. Crushing: Crushing the waste concrete to make it into recycled coarse aggregate;

[0036] S2. Screening: remove needle-like and flaky waste materials, and screen out regenerated coarse aggregates with a particle size of 12.5mm for later use;

[0037] S3. Cleaning: cleaning the surface of the recycled coarse aggregate to remove the cement mortar remaining on the surface;

[0038]S4. Mixing: Stir the recycled coarse aggregate, pebble-gravel mixture, and fine sand evenly; then add slag portland cement, fly ash, po...

Embodiment 2

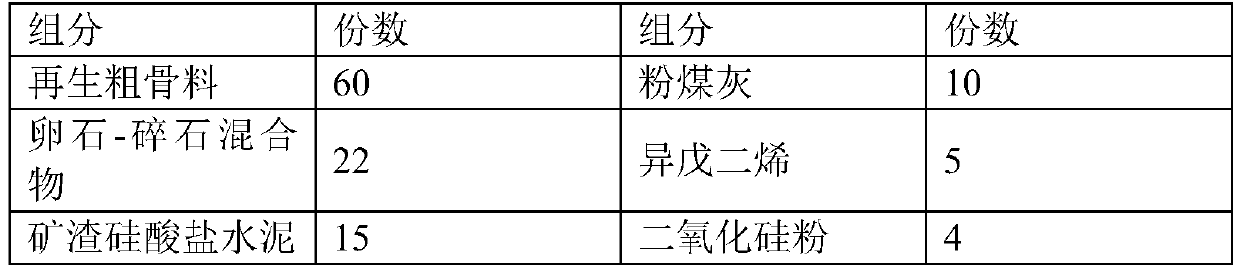

[0039] Embodiment 2 is a kind of recycled concrete disclosed by the present invention and its preparation method. The recycled concrete includes the following components by weight:

[0040]

[0041]

[0042] The mass ratio of pebble-crushed stone mixture is 1:2.5; the polypropylene fiber-glass fiber compound is put into use after surface treatment with argon plasma;

[0043] The preparation method of recycled concrete is the same as in Example 1.

Embodiment 3

[0044] Embodiment 3 is a kind of recycled concrete disclosed by the present invention and its preparation method. The recycled concrete includes the following components by weight:

[0045]

[0046] The mass ratio of pebble-crushed stone mixture is 1:2.5; the polypropylene fiber-glass fiber compound is put into use after surface treatment with argon plasma;

[0047] The preparation method of recycled concrete is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com