Two-terminal pole-type high-performance supercapacitor

A supercapacitor, high-performance technology, applied in the field of capacitors, can solve the problems of unfavorable installation of voltage acquisition harness or temperature acquisition harness, low accuracy and stability of collected data, high requirements for production and processing technology, and improve installation accuracy and installation efficiency , Reduce processing technology requirements and processing costs, and reduce equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

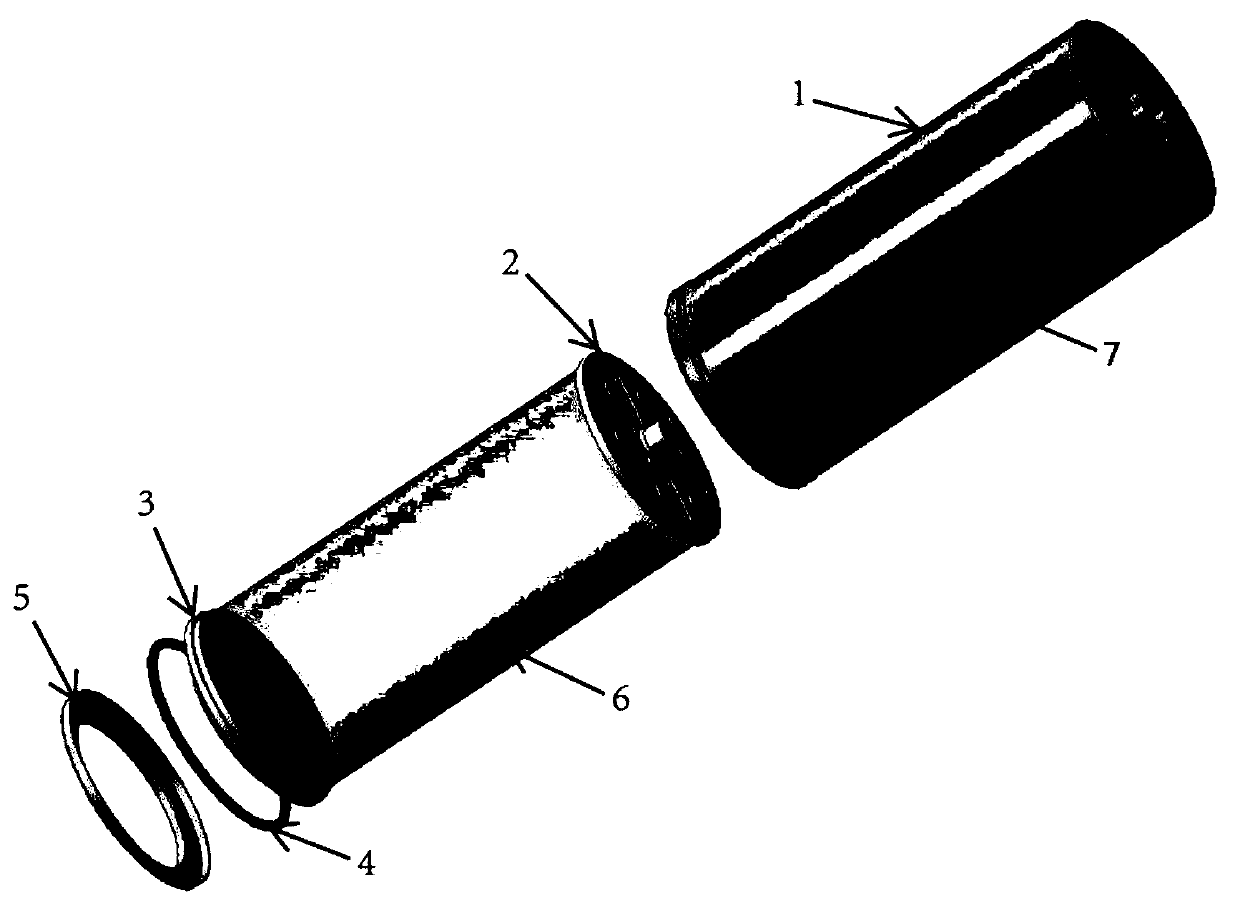

[0020] see Figure 1-3 , a high-performance welded capacitor with poles at both ends, including an aluminum shell 1, a positive current collector 2, a negative pole assembly 3, a sealing ring 4, a PFA gasket 5 and a core package 6, and the positive electrode of the positive current collector 2 The bottom end of the column is a conical surface 21 structure, and the aluminum shell 1 is also a conical surface structure 11 at the joint. The column assembly 3 has a groove design 10 at the root of the pole, and an explosion-proof valve 7 is also provided on the aluminum shell 1 .

Embodiment 2

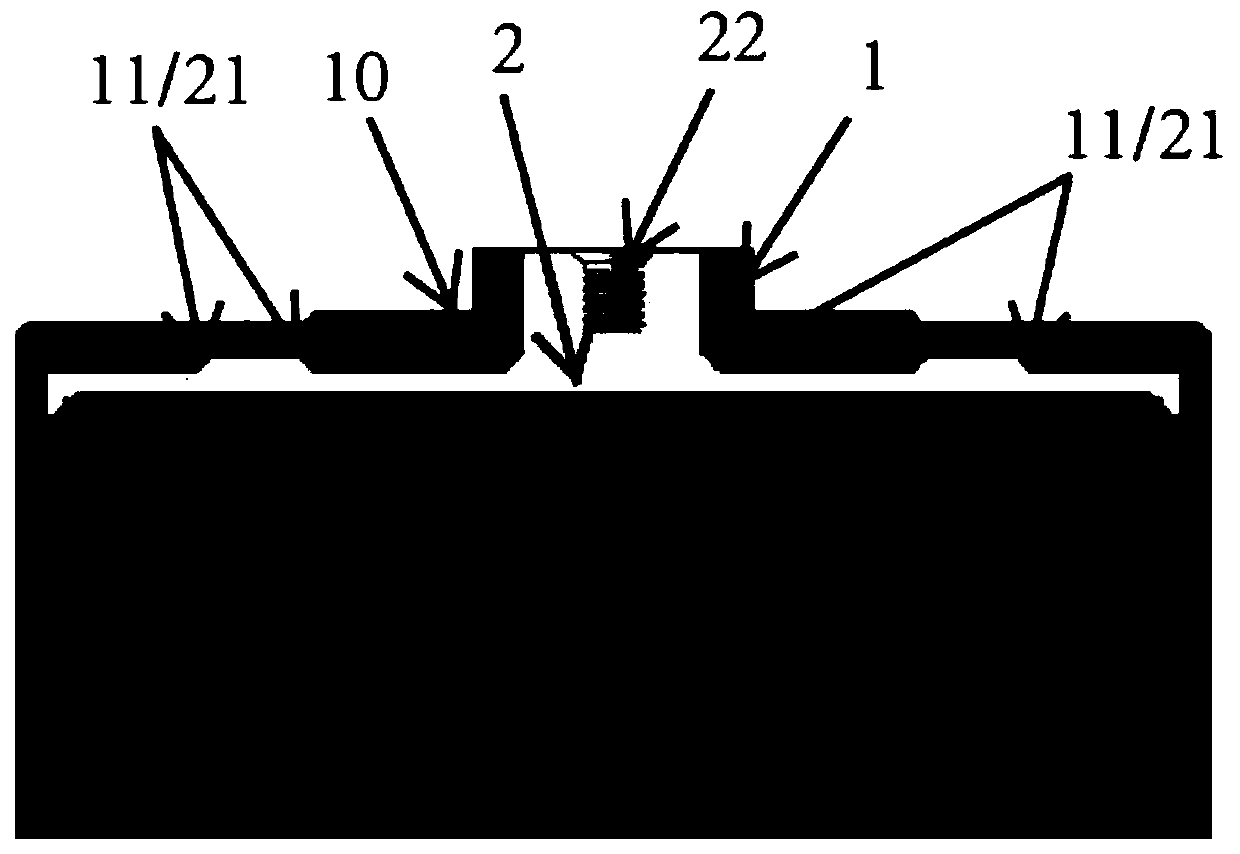

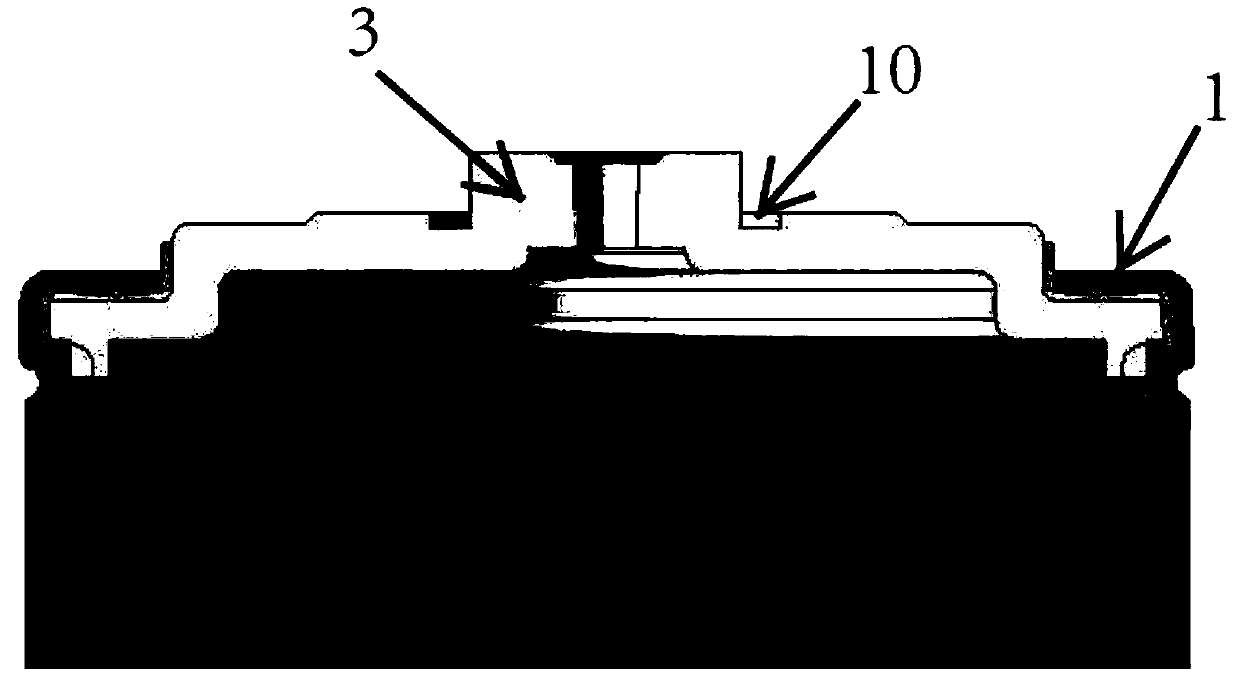

[0022] see Figure 4-5 , a two-terminal post-type high-performance bolted capacitor, including an aluminum shell 1, a positive current collector 2, a negative pole assembly 3, a sealing ring 4, a PFA gasket 5 and a core package 6, and the positive electrode of the positive current collector 2 The bottom end of the column is a conical surface 21 structure, and the aluminum shell 1 is also a conical surface structure 11 at the joint.

[0023] The two types of capacitors, welded capacitors and bolted capacitors, can meet the needs of a single unit that is suitable for multiple forms and flexibly form modules required by customers; at the same time, the core package, positive current collector, and negative pole assembly of the present invention are welded by laser, and the positive pole The current collector and the aluminum shell are also sealed by laser welding, which reduces the DC internal resistance on the one hand and enhances the sealing of the product on the other hand. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com