Electric heating chip structure, mounting method, molding method and wind-driven generator set

A technology of wind turbines and electric heating chips, which is applied in wind engines, wind engines consistent with the wind direction, and wind power generation. It can solve problems such as complex connection methods, large processing depth, and large connection space, and achieve simplified production processes. Reduce the drilling depth and reduce the effect of modification works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings, in which the same reference numerals are used to denote the same components.

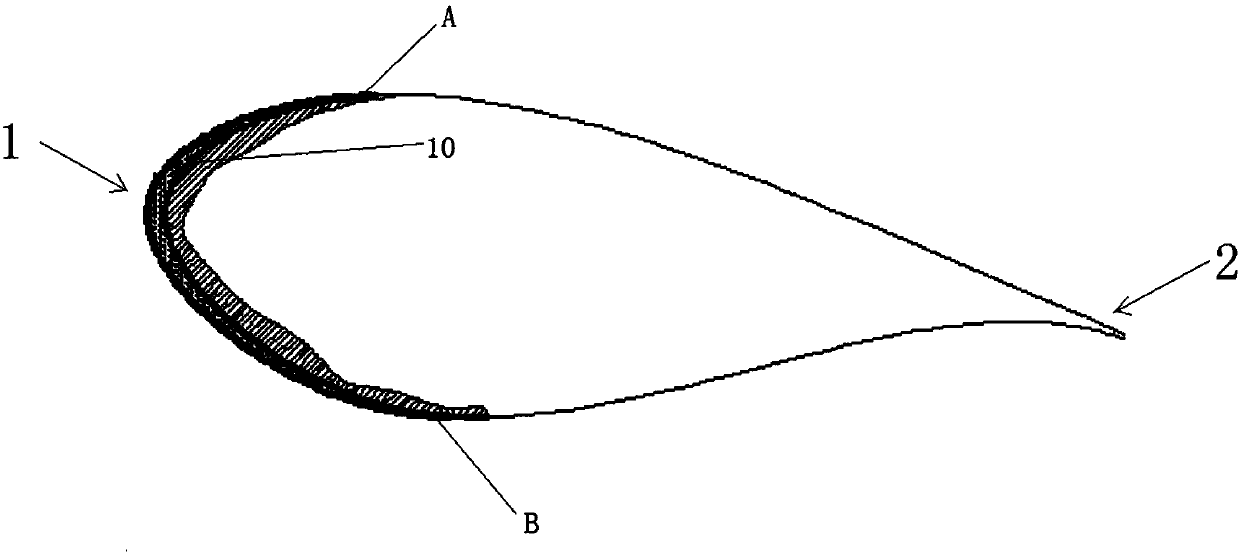

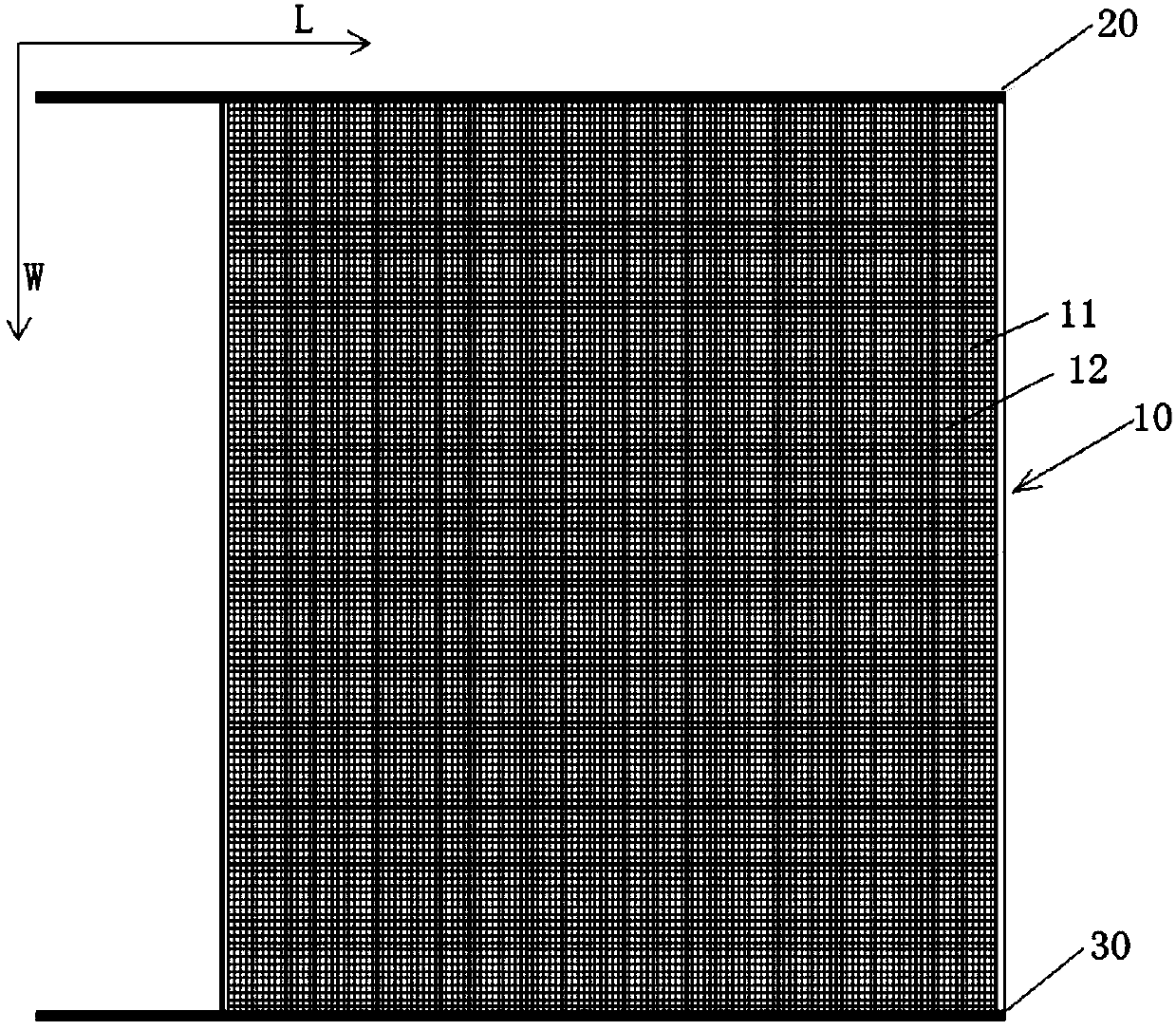

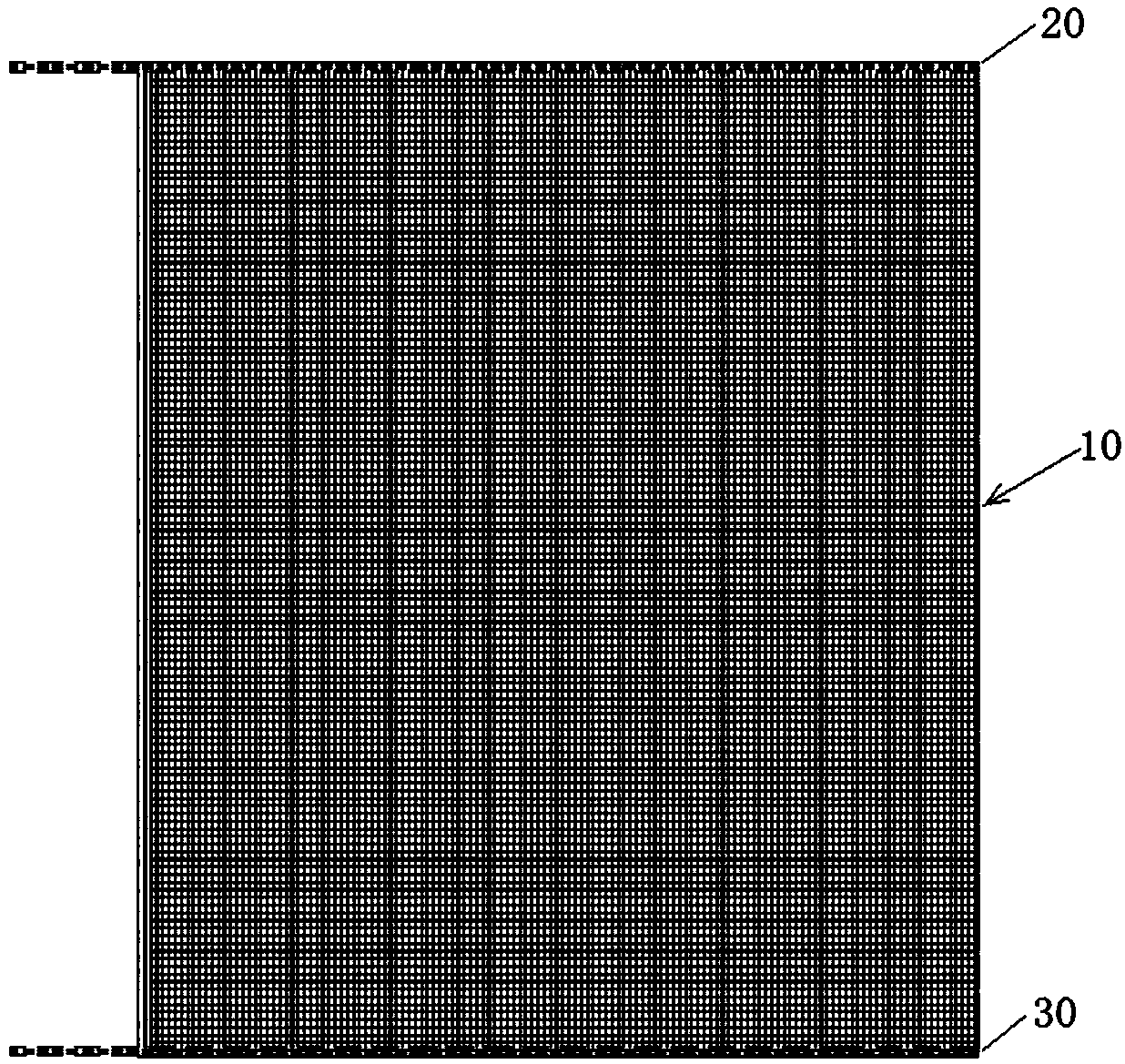

[0029] According to an exemplary embodiment of the present invention, the electrothermal chip structure for blade ice melting may include an electrothermal chip and a conductive wire, and the electrothermal chip and the conductive wire may be formed into one body and laid in the outer layer of the blade, thereby the blade can be The outer layer is heated to remove the ice layer on the outer surface of the blade, and the electric heating chip and the conductive wire are installed or laid in the outer layer of the blade to facilitate the electrical connection of the electric heating chip and improve the ice-melting efficiency. Combine below image 3 The structure of the electrothermal chip of the present invention is described in detail.

[0030] figure 1 is a schematic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com