High-efficiency pig feed and preparation method thereof

A pig feed and high-efficiency technology, applied in animal feed and other directions, can solve the problems that affect the economic benefits of farmers, affect the development cycle of fattening pigs, and low feed conversion rate, and achieve the effect of shortening the fattening cycle, good palatability, and more meat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] High-efficiency pig feed, including the following raw materials by weight: 60 parts of corn flour, 10 parts of wheat bran, 20 parts of soybean meal, 4 parts of fish meal, 0.4 part of ginger powder, 0.6 part of table salt, 0.3 part of baking soda, 4 parts of hawthorn powder, citric acid 0.3 part, vitamin premix 0.2 part, trace element premix 0.5 part.

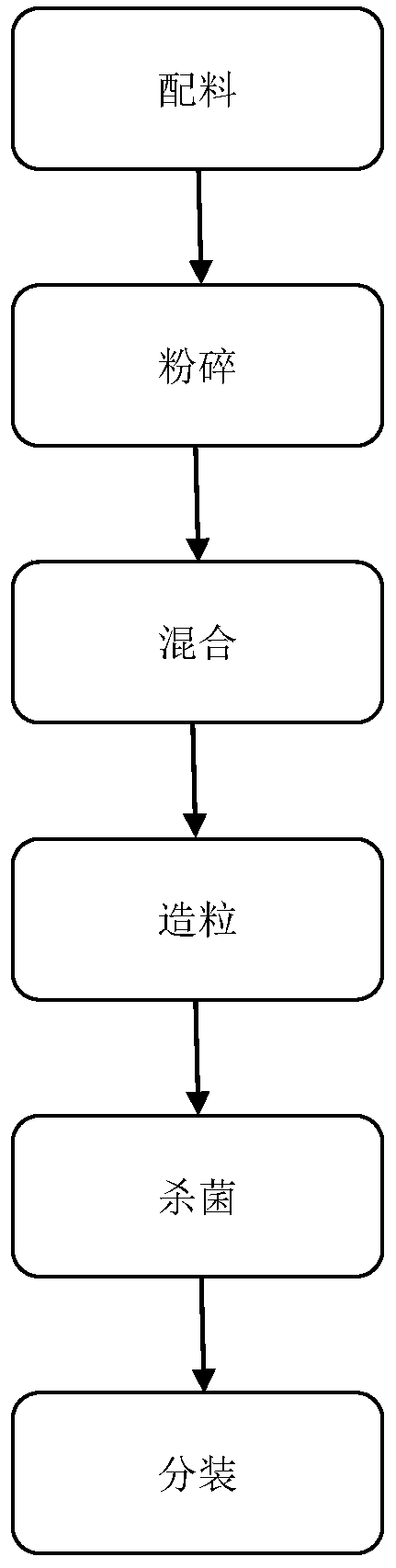

[0023] The preparation method of high-efficiency pig feed comprises the following steps:

[0024] Step 1) Ingredients: Weigh 60 parts of corn flour, 10 parts of wheat bran, 20 parts of soybean meal, 4 parts of fish meal, 0.4 part of ginger powder, 0.6 part of table salt, 0.3 part of baking soda, 4 parts of hawthorn powder, citric acid 0.3 parts, 0.2 parts of vitamin premix, 0.5 parts of trace element premix, and remove impurities respectively;

[0025] Step 2) Pulverization: adding the raw materials after impurity removal to a pulverizer respectively for pulverization, the pulverization particle size is 700 μm, and pulve...

Embodiment 2

[0031] High-efficiency pig feed, including the following raw materials by weight: 70 parts of corn flour, 20 parts of wheat bran, 30 parts of soybean meal, 8 parts of fish meal, 1 part of ginger powder, 1 part of table salt, 0.5 parts of baking soda, 8 parts of hawthorn powder, citric acid 0.6 part, vitamin premix 0.4 part, trace element premix 1 part.

[0032] The preparation method of high-efficiency pig feed adopts the same processing steps as in Example 1 for feed processing, and the crushing particle size in step 2) is 500 μm.

Embodiment 3

[0034] High-efficiency pig feed, including the following raw materials in parts by weight: 65 parts of corn flour, 15 parts of wheat bran, 25 parts of soybean meal, 6 parts of fish meal, 0.8 part of ginger powder, 0.8 part of table salt, 0.4 part of baking soda, 6 parts of hawthorn powder, citric acid 0.4 part, vitamin premix 0.3 part, trace element premix 0.8 part.

[0035] The preparation method of high-efficiency pig feed adopts the same processing steps as in Example 1 for feed processing, and the crushing particle size in step 2) is 600 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com