Method for conducting sulfur-containing flue gas desulfuration by means of alkaline waste

A waste residue and alkaline technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low desulfurization efficiency, and achieve the effects of high desulfurization efficiency, improved dissolution rate, and improved desulfurization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

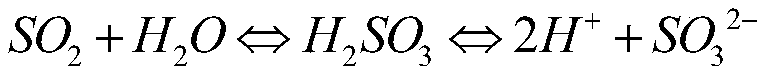

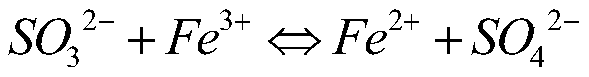

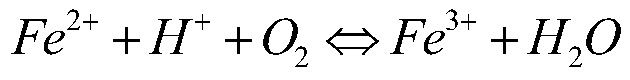

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Using industrial waste iron-containing waste acid to add water to prepare Fe-containing 3+ waste acid, preparation of red mud slurry, preparation of phosphate rock slurry, preparation of magnesium ore slurry, preparation of copper ore slurry. Fe-containing 3+ The waste acid concentration is 0.5%, red mud (the main component mass percentage of red mud solid is Al 2 o 3 20%, SiO 2 8%, Fe 2 o 3 35%, CaO 12%, Na 2 O 5%, TiO 2 3%), phosphate rock (the mass percentage of the solid component of phosphate rock is P 2 o 5 31.54%, CaO 43.5%, SiO 2 14.92%, Al 2 o 3 2.05%, Fe 2 o 3 1.22%, MgO 0.13%, other 6.64%), magnesium ore (magnesium ore solid main component mass percentage is MgO 21%, SiO 2 3%, Al 2 o 3 0.1%, Fe 2 o 3 0.2%, CaO 1%), copper ore (copper ore solid main component mass percentage is Cu0.45%, Fe 44%, Fe 3 o 4 4%, CaO 3%, Al 2 o 3 8%, MgO 1%, SiO 2 31%, S 1%). Grind the red mud solid to 100 mesh, and mix the ground red mud and wa...

Embodiment 2

[0061] Using industrial waste iron-containing waste acid to add water to prepare Fe-containing 3+ Waste acid, preparation of red mud slurry, preparation of phosphate rock slurry, preparation of magnesium ore slurry, preparation of copper ore slurry. Fe-containing 3+ The concentration of waste acid solution is 0.6%, red mud (the main component mass percentage of red mud solid is Al 2 o 3 18%, SiO 2 10%, Fe 2 o 3 25%, CaO 15%, Na 2 O 2%, TiO 2 21%), phosphate rock (the mass percentage of the solid main component of phosphate rock is P 2 o 5 23.94%, CaO 41.48%, SiO 2 8.37%, Al 2 o 3 1.37%, Fe 2 o 3 1.57%, MgO 3.65%), magnesium ore (magnesium ore solid main component mass percentage is MgO 31%, SiO 2 2%, Al 2 o 3 0.2%, Fe 2 o 3 0.04%, CaO 3%), copper ore (copper ore solid main component mass percentage is Cu0.9%, Fe 34%, Fe 3 o 4 4%, CaO 5%, Al 2 o 3 5%, MgO 1%, SiO 2 32%, S 1%). Grind the red mud solid to 100 mesh, and mix the ground red mud an...

Embodiment 3

[0064] Using industrial waste iron-containing waste acid to add water to prepare Fe-containing 3+ Waste acid, preparation of red mud slurry, preparation of phosphate rock slurry, preparation of magnesium ore slurry, preparation of copper ore slurry. Fe-containing 3+ The concentration of waste acid solution is 0.7%, red mud (the main component mass percent of red mud solid is Al 2 o 3 25%, SiO 2 14%, Fe 2 o 3 40%, CaO 16%, Na 2 O 8%, TiO 2 4%), phosphate rock (the mass percentage of the solid main component of phosphate rock is P 2 o 5 32.07%, CaO 46.95%, SiO 2 4.68%, Al 2 o 3 6.00%, Fe 2 o 3 2.68%, MgO 2.59%), magnesium ore (magnesium ore solid main component mass percentage is MgO 66%, SiO 2 1%, Al 2 o 3 0.2%, Fe 2 o 3 0.04%, CaO 2%), copper ore (copper ore solid main component mass percentage is Cu0.6%, Fe 37%, Fe 3 o 4 3%, CaO 8%, Al 2 o 3 5%, MgO 1%, SiO 2 32%, S 2%). Grind the red mud solid to 400 mesh, and mix the ground red mud and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com