Sulfur hexafluoride adsorbent recovery treatment system and method based on ultrasonic cavitation effect

A technology of adsorbent recovery and sulfur hexafluoride, which is applied in separation methods, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of low regeneration efficiency, high economic cost and few practical applications of solvent regeneration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

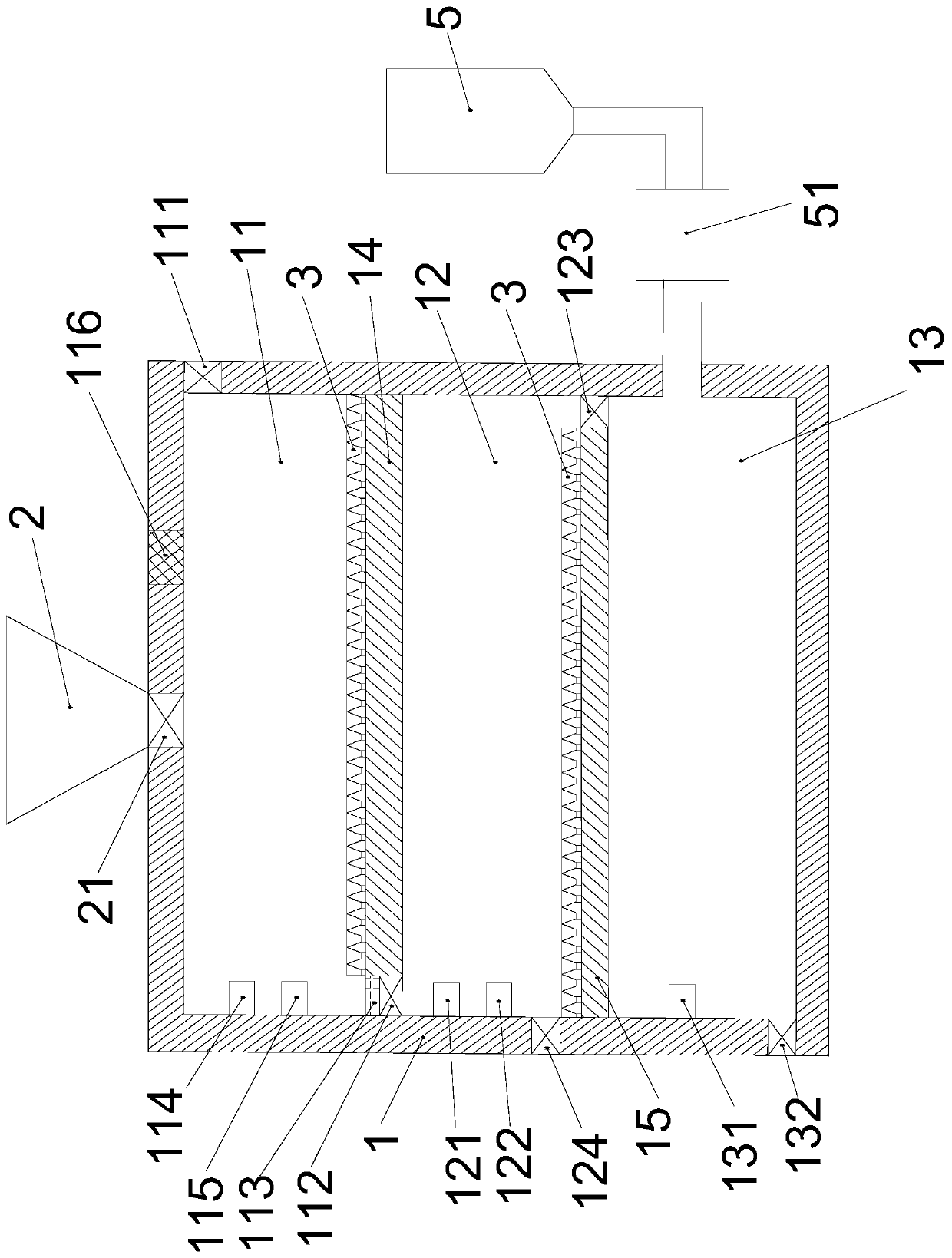

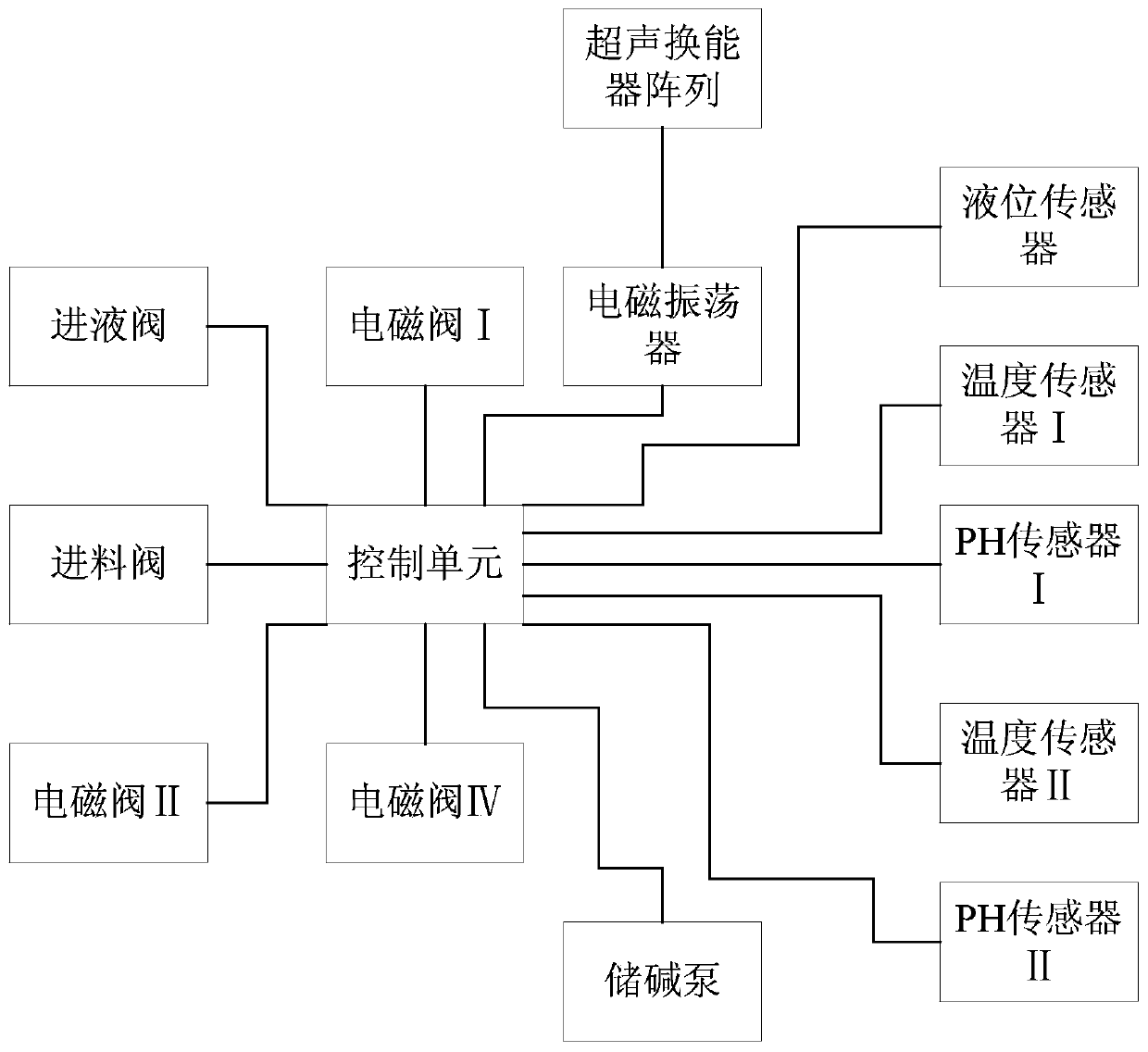

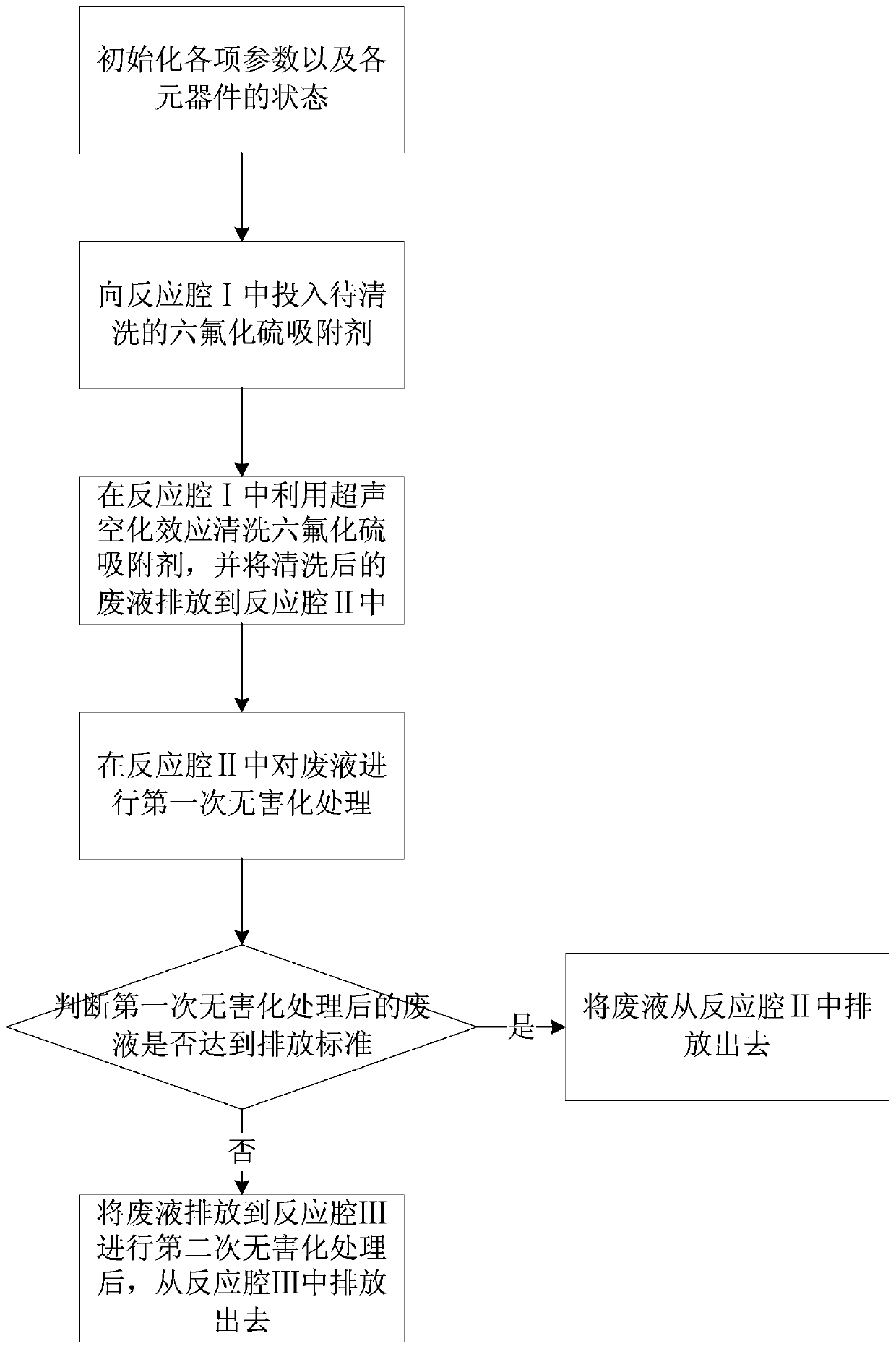

[0072] like figure 1 and figure 2 As shown, a kind of sulfur hexafluoride adsorbent recycling system based on the ultrasonic cavitation effect provided by the present invention includes a reaction box 1 and a feeding unit 2;

[0073] The feeding unit 2 is fixedly arranged directly above the reaction box 1 and communicates with the reaction box 1, and is used to put sulfur hexafluoride adsorbent to be cleaned into the reaction box 1; the upper part of the side wall of the reaction box 1 is provided with a The liquid inlet for cleaning the liquid cleaning agent of the sulfur hexafluoride adsorbent is put into the reaction box 1, and the liquid inlet is communicated with the liquid storage device storing the liquid cleaning agent; the side wall of the reaction box 1 is provided with a Drain the liquid in the reaction box 1 from the liquid outlet I of the reaction box 1; in this embodiment, the feeding unit 2 is a hopper with a weighing function, which is an existing product and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com