Lithium ion battery negative electrode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of unstable structure of graphite crucible waste, high price of needle coke raw materials, and low degree of graphitization, etc. The effect of excellent chemical properties, less impurities and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Correspondingly, the present invention also provides a kind of preparation method of above-mentioned negative electrode material of lithium ion battery, comprises the following steps:

[0042] S1. Add the artificial graphite electrode fragments to the iron remover to remove iron;

[0043] Since the artificial graphite electrode will be mixed with some iron during the preparation process, if the iron content in the negative electrode material of the lithium-ion battery is too much, it will affect the performance of the lithium-ion battery.

[0044] Specifically, the artificial graphite electrode fragments are added to the permanent magnetic iron remover, wherein the magnetic flux of the permanent magnetic iron remover is greater than 8000Gs.

[0045] Preferably, the magnetic flux of the permanent magnet iron remover is 8000-13000Gs. If the magnetic flux of the permanent magnetic iron remover is less than 8000Gs, the amount of iron removal will not reach the preset value. ...

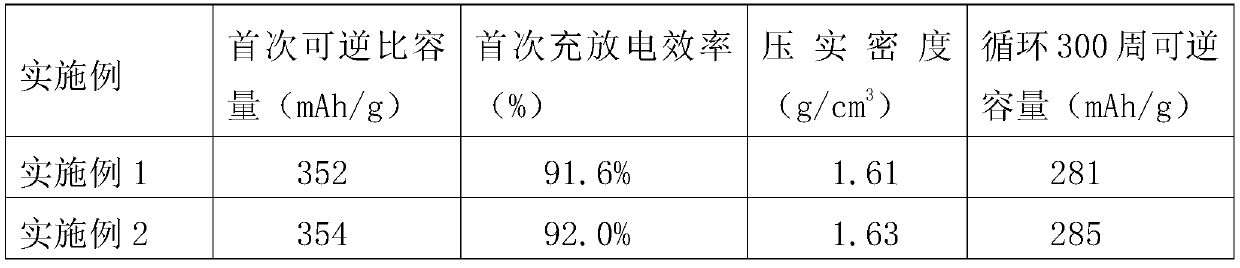

Embodiment 1

[0062] A preparation method for a lithium ion battery negative electrode material, comprising the following steps:

[0063] S1. Add artificial graphite electrode fragments into the hopper, and put them into the iron remover through the hopper. The magnetic flux of the iron remover is 8000Gs, and the feeding speed is 10-30kg / min to remove iron;

[0064] S2, crushing the artificial graphite electrode after iron removal to obtain artificial graphite electrode powder, the particle size distribution of the artificial graphite electrode powder is: D50=11 μm;

[0065] S3, spheroidizing and grading the artificial graphite electrode powder to obtain the artificial graphite electrode powder, the particle size distribution of the artificial graphite electrode powder is: D10=6 μm, D50=15 μm, D90=30 μm, the tap density of the artificial graphite electrode powder 0.8g / cm 3 , the specific surface area is 6.5m 2 / g;

[0066] S4, adding the artificial graphite electrode powder into the dema...

Embodiment 2

[0069] A preparation method for a lithium ion battery negative electrode material, comprising the following steps:

[0070] S1. Put artificial graphite electrode fragments into the hopper, and put them into the iron remover through the hopper. The magnetic flux of the iron remover is 10000Gs, and the feeding speed is 10-30kg / min to remove iron;

[0071] S2, crushing the artificial graphite electrode after iron removal to obtain artificial graphite electrode powder, the particle size distribution of the artificial graphite electrode powder is: D50=15 μm;

[0072] S3, spheroidizing and grading the artificial graphite electrode powder to obtain the artificial graphite electrode powder, the particle size distribution of the artificial graphite electrode powder is: D10=8 μm, D50=18 μm, D90=33 μm, the tap density of the artificial graphite electrode powder 0.85g / cm 3 , the specific surface area is 6.0m 2 / g;

[0073] S4, adding the artificial graphite electrode powder into the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic flux | aaaaa | aaaaa |

| Magnetic flux | aaaaa | aaaaa |

| Magnetic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com