Device and method for reducing dissolved oxygen in cold water in generator

A technology of dissolved oxygen and generator, applied in chemical instruments and methods, water, inorganic chemistry, etc., can solve problems such as adverse effects on safe operation of generators, copper wire rod corrosion, and copper corrosion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

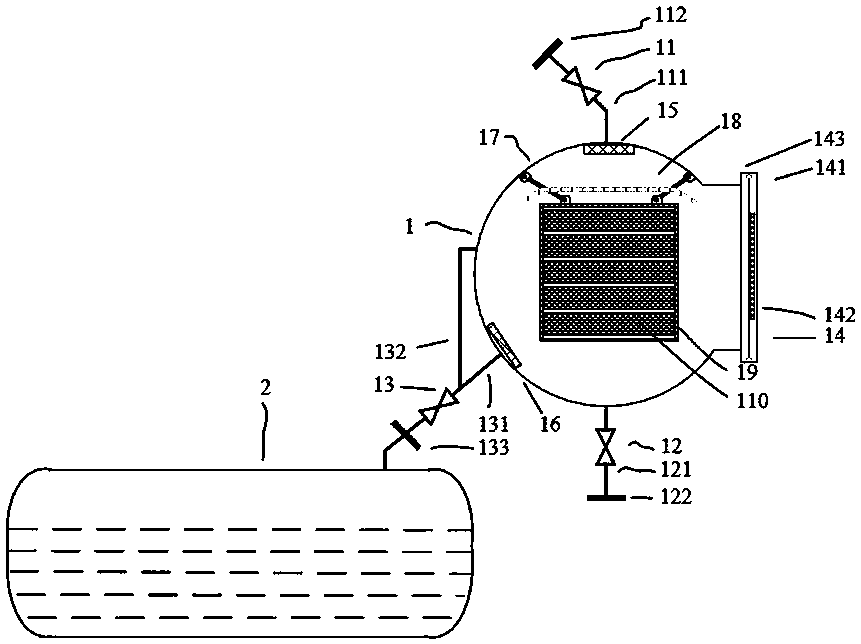

[0022] The device for reducing the amount of dissolved oxygen in the inner cooling water of the generator according to the present invention includes a catalytic tank 1 and an inner cooling water tank 2; figure 1 As shown, the catalytic tank 1 is provided with a catalyst frame 19; a hanger 17 is arranged between the catalyst frame 19 and the inner wall of the catalytic tank 1; Tube; the height of the catalytic tank 1 in the vertical direction is greater than the height of the inner cooling water tank 2 in the vertical direction; the catalyst frame 19 is provided with a catalyst 110, and in this embodiment the catalyst 110 is a palladium catalyst 110 , The palladium catalyst 110 is used to catalyze the reaction of hydrogen and oxygen to produce water. The communication pipe includes a first communication pipe 131 and a second communication pipe 132; the first communication pipe 131 is sequentially provided with a communication valve 13 and a communication pipe flange 133; A se...

Embodiment 2

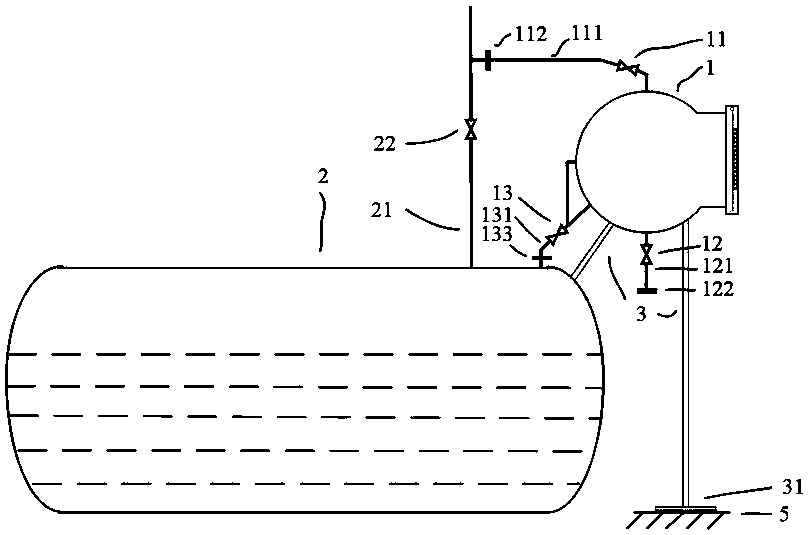

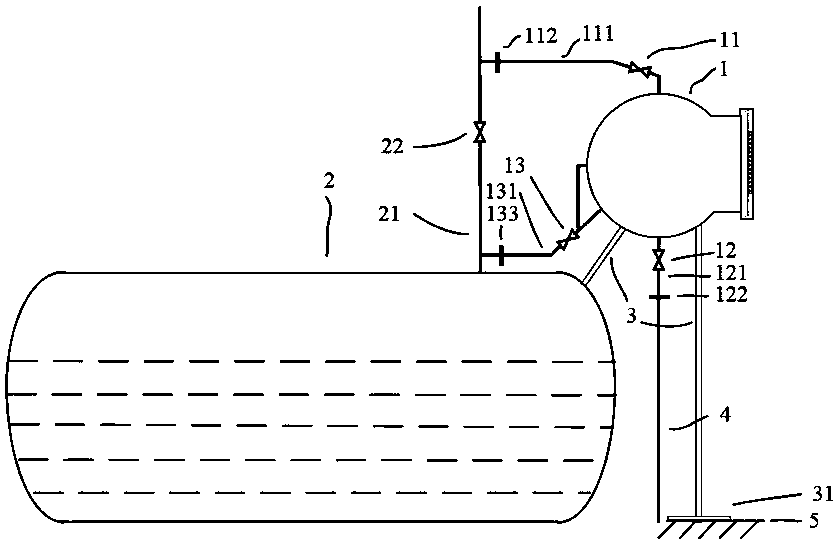

[0027] On the basis of Example 1, as image 3As shown, in this embodiment, the device installation method for reducing the dissolved oxygen in the inner cooling water of the generator is as follows: the catalytic tank 1 is installed above the side of the inner cooling water tank 2, fixed by brackets 3, and a set of brackets 3 connects the catalytic tank 1 and the inner cooling water Box 2, another set of brackets 3 are connected to the catalytic tank 1 and the bracket base 31, and the bracket base 31 is fixed on the ground 5.

[0028] The inner cooling water tank 2 is equipped with an inner cooling water tank exhaust pipe 21, on which an inner cooling water tank exhaust valve 22 is connected in series. The exhaust pipe 111 is connected to the internal cooling water tank exhaust pipe 21 on the top of the internal cooling water tank exhaust valve 22 through the exhaust pipe flange 112 . The first communication pipe 131 of the catalytic tank 1 is connected to the inner cooling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com