HRB400 alloy steel containing Nb and V and smelting process method thereof

A technology of alloy steel and process, applied in the field of HRB400 alloy steel and its smelting process, can solve problems such as poor temperature control, increased consumption of steel materials, and decreased alloy absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

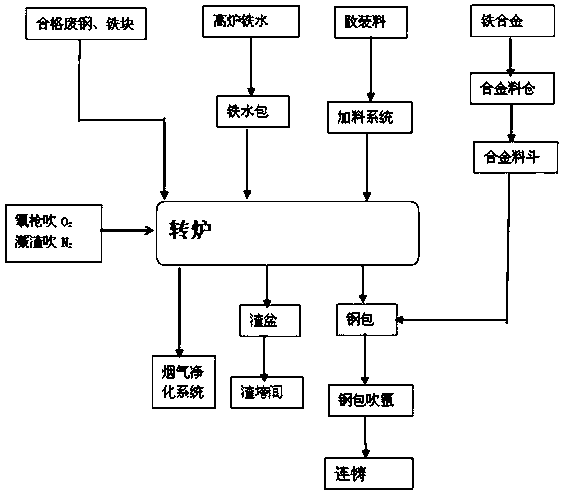

Image

Examples

Embodiment Construction

[0023] A HRB400 alloy steel containing Nb and V, which comprises the following components: C: 0.21-0.25%; Si: 0.40-0.55%; Mn: 1.35-1.50; P≤0.045%; S: ≤0.045%, V: 0.010%-0.015%; Nb0.005%-0.015%, the rest is Fe.

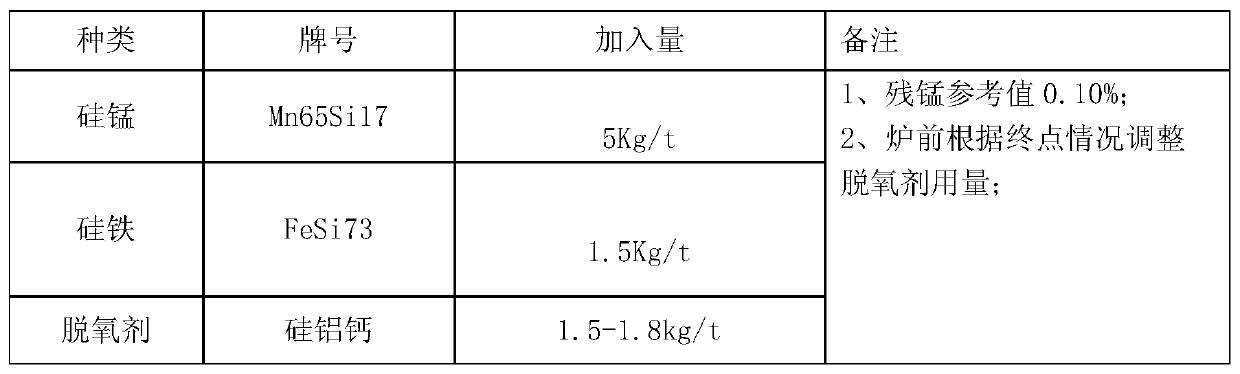

[0024] A kind of smelting process of HRB400 alloy steel containing Nb, V, it comprises the steps:

[0025] ——Material loading, add scrap steel and molten iron into the steelmaking furnace according to the proportion; generally, the total amount of loading is 91±2t, of which molten iron is 67±2t and scrap steel is 24±2t;

[0026] ——Variable pressure and gun operation, control oxygen pressure and gun position, adopt low gun position operation before the end of smelting, oxygen pressure is not less than 0.70MPa;

[0027] ——Slag making control, adopt single slag method, the first batch of slag is controlled according to 2 / 3 of the total amount added, the second batch of slag is added evenly according to the principle of "small amount, frequent addition, and batches", and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com