Multilayer graphene and its preparation method

A multi-layer graphene and graphene technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of difficulty in guaranteeing the quality of multi-layer graphene, which cannot be prepared in large quantities, and achieve amplification Production, effect of good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

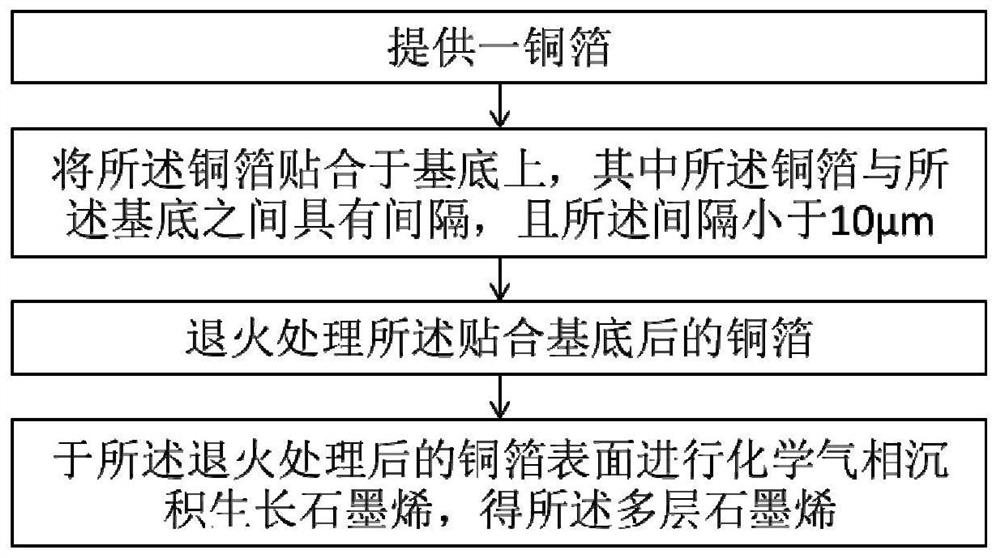

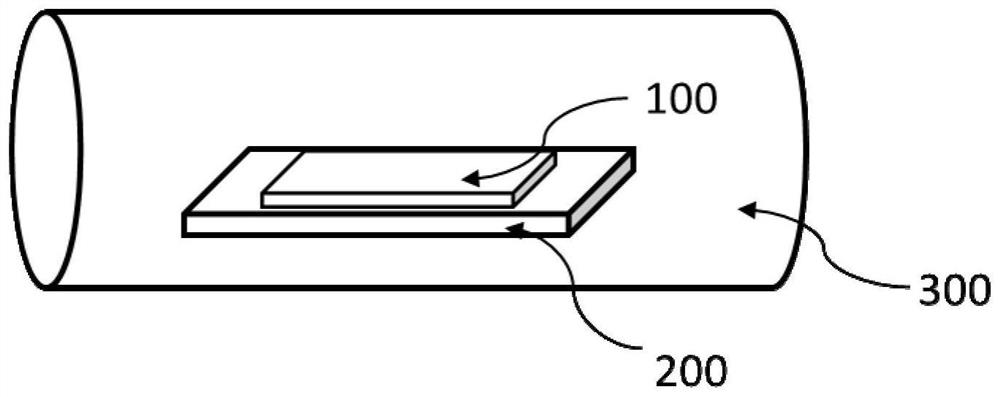

[0043] figure 1 Representatively shows a flow chart of the preparation process of multi-layer graphene according to an exemplary embodiment of the present invention. figure 2 show figure 1 schematic diagram of the device. combine figure 1 and figure 2 As shown, in the present embodiment, the preparation method of the multilayer graphene provided by the invention comprises steps as follows:

[0044] A copper foil 100 is provided, wherein the thickness of the copper foil 100 can generally be 15 μm˜250 μm, but the invention is not limited thereto. In some embodiments, the copper foil may be electrochemically polished in advance to make the surface of the copper foil more smooth. Specifically, for example, a phosphoric acid: ethylene glycol solution with a volume ratio of 3:1 is used as the polishing solution, the negative pole is copper plate, the positive pole is copper foil, and the electrochemical polishing process is performed at a voltage of 1.5-2.0V for about 20-30 m...

Embodiment 1

[0055] Embodiment 1: the preparation of multilayer graphene in 1 inch pipe diameter CVD system

[0056] Step (1): Electrochemical polishing is performed on copper foil with a thickness of 25 μm. Among them, phosphoric acid: ethylene glycol solution with a volume ratio of 3:1 is used as the polishing liquid, the negative pole is graphite plate, the positive pole is copper foil, the voltage is 1.5-2.0V, and the polishing time is 20-30min.

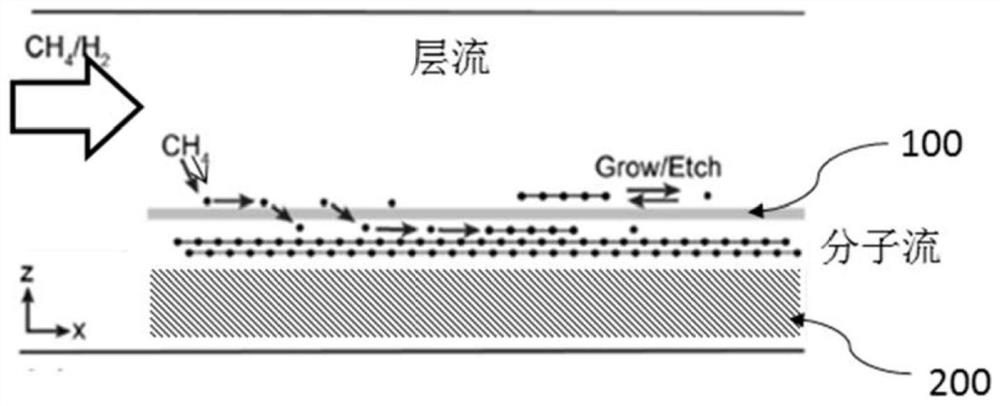

[0057] Step (2): Attach the electrochemically polished copper foil to the quartz plate, and then place it in the CVD system. The gap between the copper foil and the quartz plate is as follows: Figure 12 As shown, it is about 5 μm. Under this condition, the gas flow on the lower surface of the copper foil during the growth process is a molecular flow, and the gas flow on the upper surface of the copper foil is a laminar flow.

[0058] Step (3): Increase the temperature in the tube furnace to 1000°C within 1 hour, then maintain the temperatu...

Embodiment 2

[0061] Embodiment 2: Preparation of multilayer graphene on copper foil in 2-inch pipe diameter CVD system

[0062] Step (1): same as Example 1;

[0063] Step (2): The electrochemically polished copper foil is attached to a quartz plate, and placed in a CVD system with a pipe diameter of 2 inches, and the others are the same as in Example 1;

[0064] Step (3): same as embodiment 1;

[0065] Step (4): Pass 4000sccm H 2 and 4 sccm CH 4 , keep the pressure at 4kPa, and grow for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com