Body-in-white structure optimization design method and body-in-white structure optimization design device

An optimized design and body-in-white technology, applied in computing, instrumentation, electrical digital data processing, etc., can solve problems such as poor optimization reliability and difficulty in screening variables in body-in-white structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

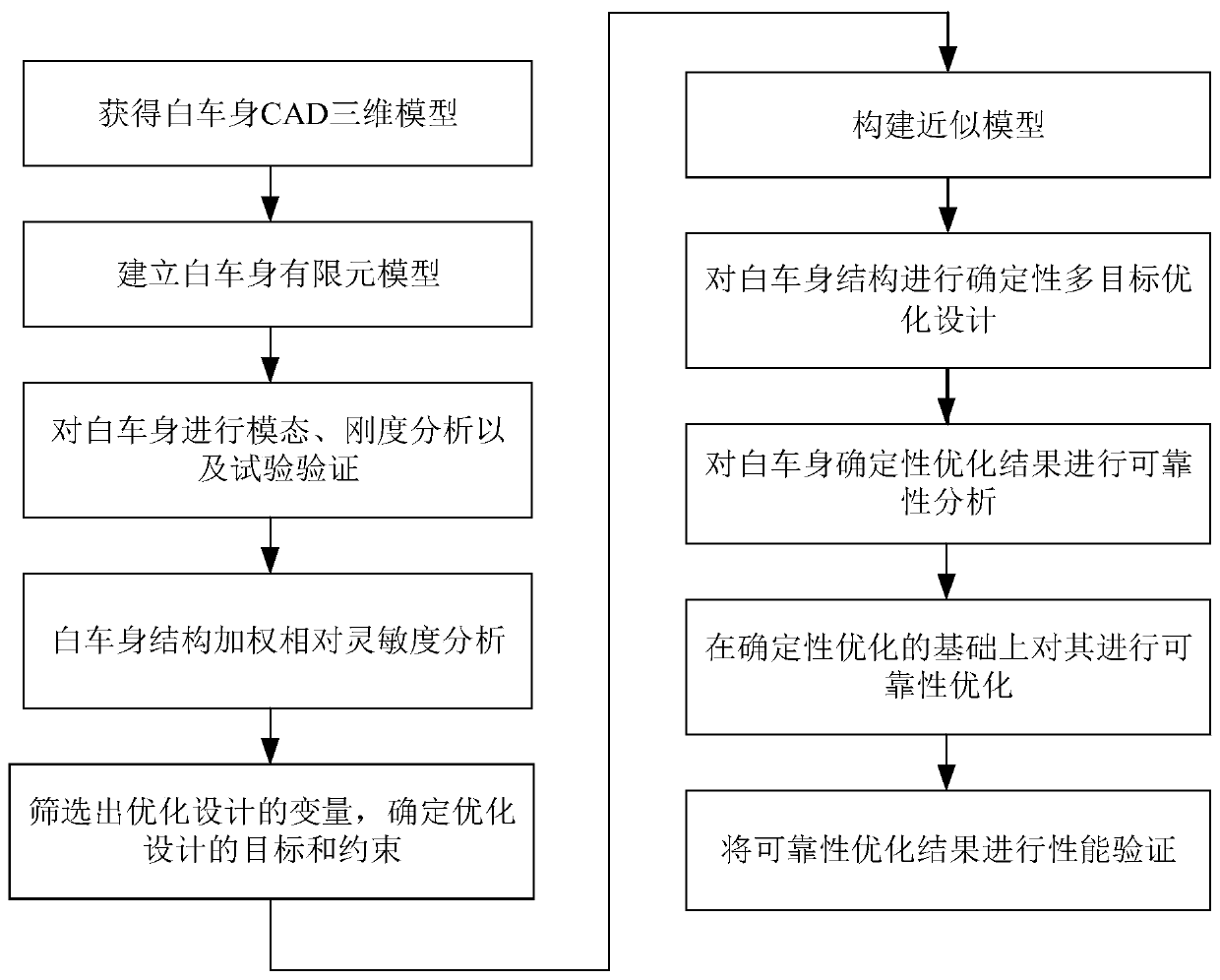

[0091] see figure 1 , the present embodiment provides a weighted relative sensitivity-based optimal design method for the body-in-white structure, which includes the following four steps (steps 1 to 4), and of course other steps may also be included in some other embodiments.

[0092] Step 1. Obtain the 3D model of the body in white first, then divide the 3D model into a finite element mesh to establish a corresponding finite element model of the body in white, and finally check the mesh quality of the finite element model. In this embodiment, first, obtain the body-in-white CAD three-dimensional model, convert the file format of the body-in-white three-dimensional model into a common format.stp or.igs format (of course, in other embodiments, the common format can also be other common formats ), and then import the BIW 3D model file converted into a common format into hypermesh for finite element mesh division, and finally check the mesh quality of the divided finite element m...

Embodiment 2

[0146] This embodiment provides a body-in-white structure optimization design method based on weighted relative sensitivity, and a specific implementation case is carried out on the basis of Embodiment 1.

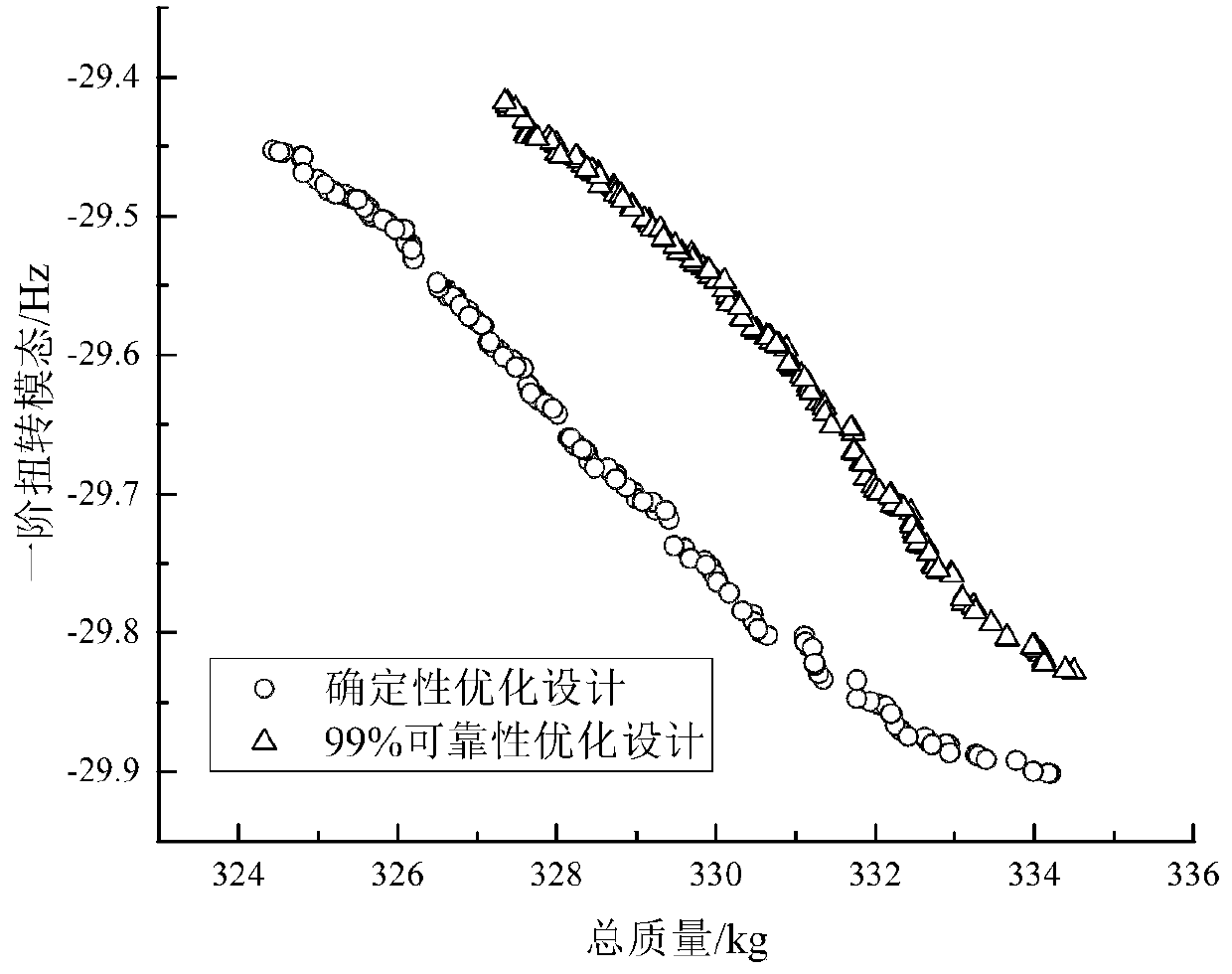

[0147] (1) Firstly, finite element modeling is carried out on the body-in-white by referring to the modeling standard of the enterprise, the modal and stiffness of the body-in-white are calculated, and the test is carried out to verify it, so as to ensure that the error between the simulation and test results is less than 10%, and a part of the body-in-white is obtained. The first-order torsional modal frequency is 28.17Hz, the first-order bending modal frequency is 43.50Hz, the bending stiffness is 15748.03N / mm, and the torsional stiffness is 14925.37N·m / °.

[0148] Since the frequency range of the engine idle state is 23.3-26.7Hz, the overall modal frequency of the body should be higher than the engine idle frequency by more than 2Hz, but because the first-order torsional ...

Embodiment 3

[0168]This embodiment provides a body-in-white structure optimization design device based on weighted relative sensitivity, the device includes a finite element model generation module, an analysis and verification module, a design variable screening module and an optimization design module.

[0169] The finite element model generation module is used to divide the finite element mesh of the 3D model of the body-in-white and establish the corresponding finite element model.

[0170] The analysis and verification module is used to calculate the mode and stiffness of each working condition in the finite element model, and conduct test verification on the body in white to obtain the error between the calculated value and the test value of the mode and stiffness. When the error is not less than a preset percentage, the analysis verification module adjusts the finite element model until the error is smaller than the preset percentage.

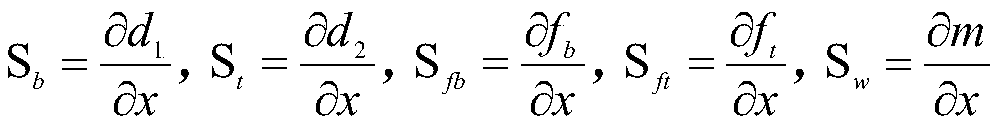

[0171] The design variable screening module is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending stiffness | aaaaa | aaaaa |

| Torsional stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com