Flux-adjustable magnet vane structure for permanent magnet motor rotor

A permanent magnet motor and magnetic isolation plate technology, applied in the shape/style/structure of the magnetic circuit, the rotating parts of the magnetic circuit, the magnetic circuit, etc. The effect of improved operation, lower cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

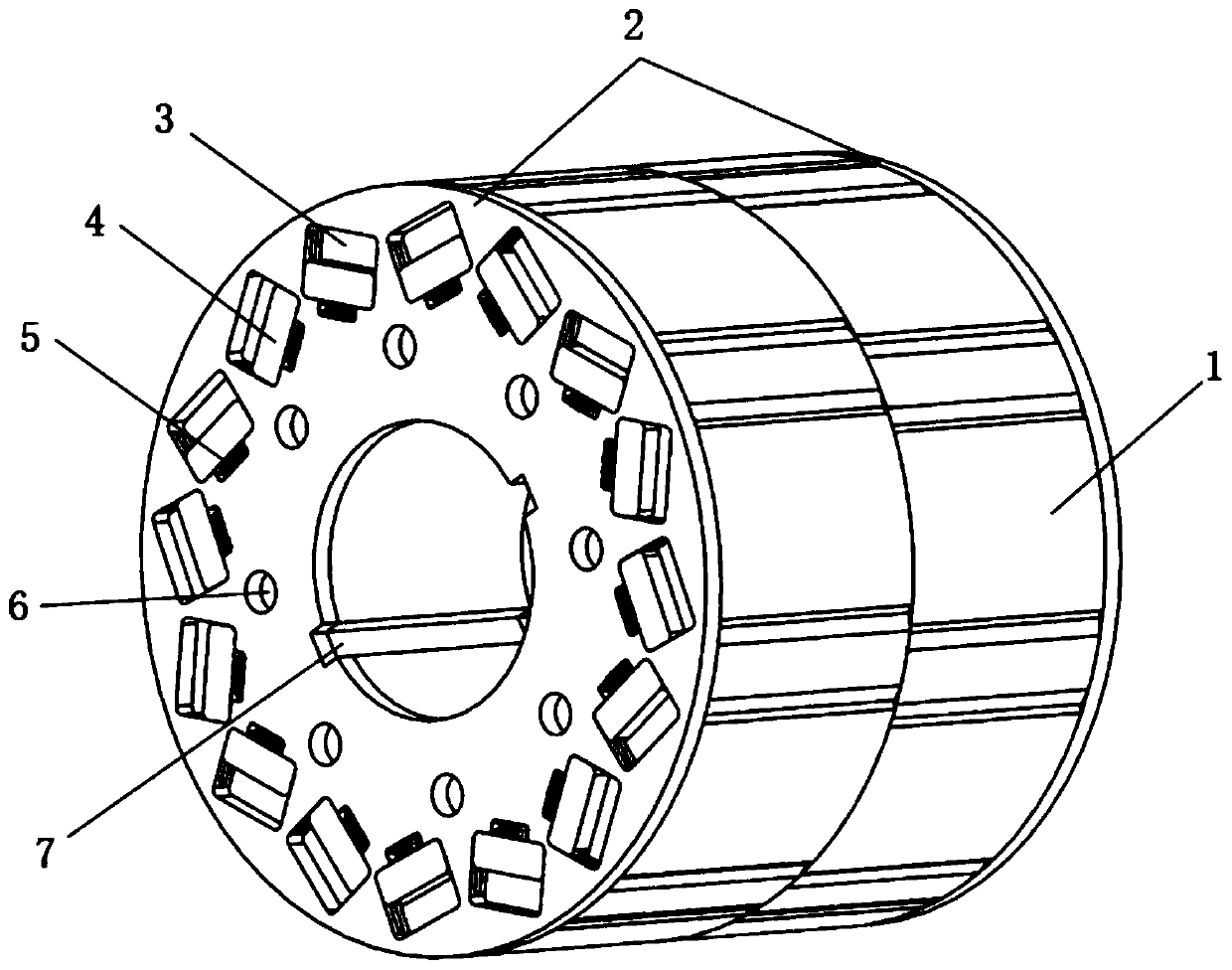

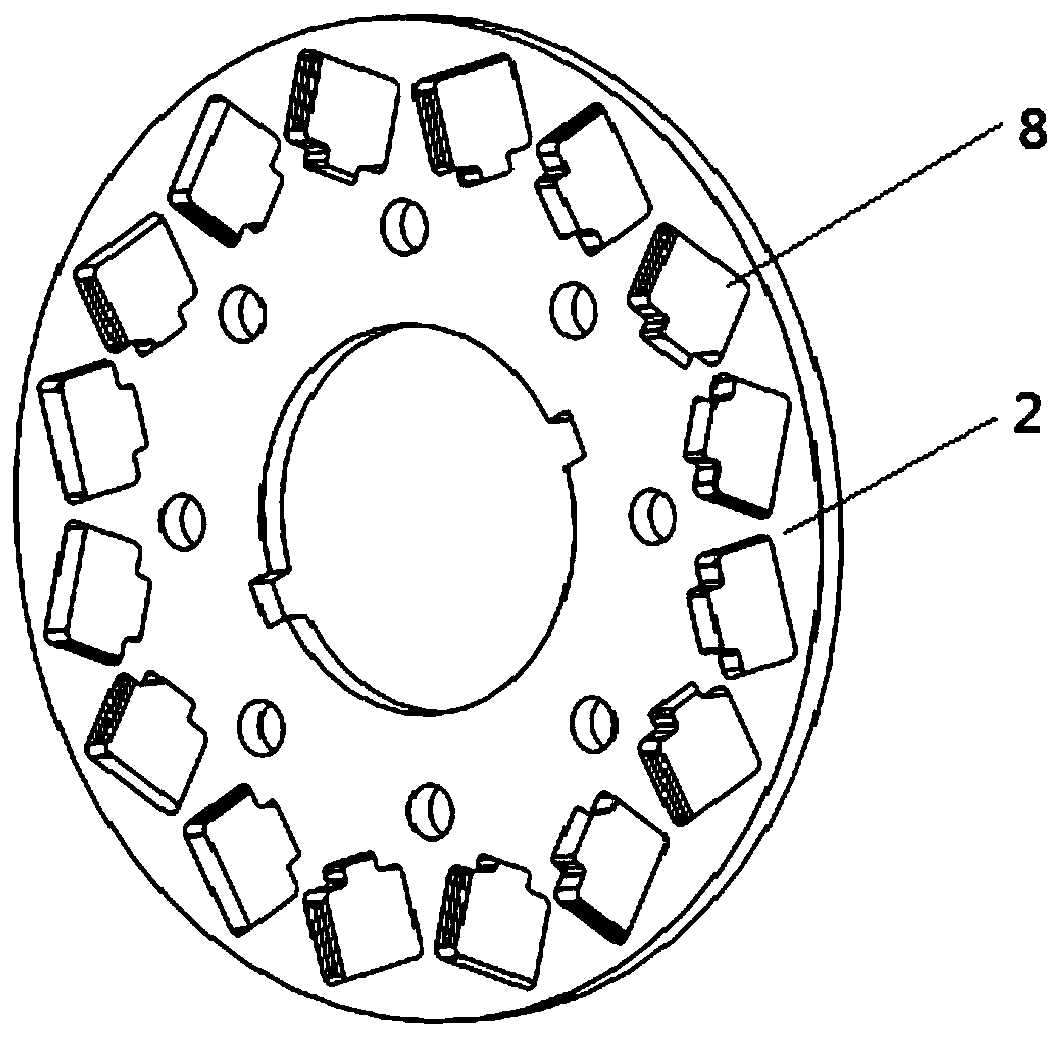

[0037] see figure 1 Among them, 8 sets of V-shaped magnetic steel grooves are embedded on the rotor core, and each V-shaped magnetic steel groove is embedded with a set of magnetic steel. Both ends of the rotor core are respectively equipped with magnetic isolation plates. There are 16 slider holes that correspond to the magnetic steel one by one. Among them, there is an included angle between every two slider holes. This included angle is consistent with the V-shaped included angle of the V-shaped magnetic steel groove. The area of the block hole is larger than the area of the magnetic steel groove, and the length direction of the slider hole is smaller than the length of the magnetic steel to ensure that the magnetic steel will be blocked when the rotor moves and will not be thrown out. The width direction of the slider hole is the magnetic steel. 2-2.5 times the width of the steel to ensure that the slider can effectively cover the area of the magnetic steel when it m...

Embodiment 2

[0048] The rotor iron core is made of laminated rotor punching sheets. There are through holes and key slots on the iron core. The slot holes for placing magnetic steel on the rotor punching sheet form a V-shaped structure in pairs. Correspondingly, the slider holes are also in pairs. A V-shaped layout.

[0049] Furthermore, a mounting hole is provided at the center of the rotor core, and a set of corresponding key grooves 7 is provided on the inner wall of the mounting hole. A group of through holes are distributed around the mounting hole, and the positions of the through holes match the holes of the sliders. A through hole 6 is correspondingly provided at the gap position between the block holes.

[0050] The main body of the slider hole is a square groove for placing the slider. The inner side of the square groove is provided with a hole for placing an elastic member. The width of the hole for placing the elastic member is 1 / 4 of the width of the slider hole, and the lengt...

Embodiment 3

[0061] The rotor iron core is made of laminated rotor punches, with through holes and key slots on the iron core, and the structure of the rotor punches is V-shaped.

[0062] There is a slider hole on the magnetic isolation plate, the hole is parallel to the magnetic steel groove, grooves are provided on both sides of the slider hole, the function is to make the slider slide; the length of the slider hole is slightly smaller than the length of the magnetic steel to prevent the magnetic steel from being thrown out.

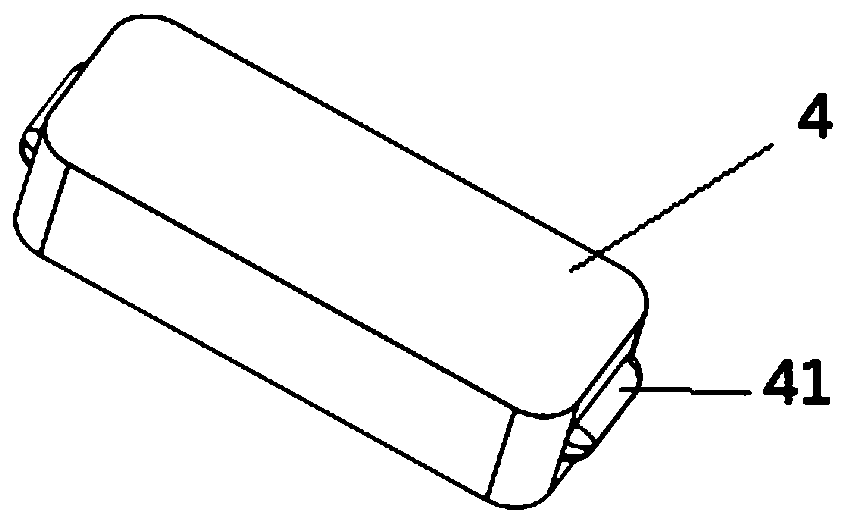

[0063] The slider is made of magnetically conductive material, and there are convex strips 41 on both sides of the slider, which are in the shape of arc strips and fit with the grooves on both sides of the hole of the slider. The slider width is the same as the permanent magnet width.

[0064] The spring connects the slider to the inner wall of the slider hole. In the natural state, the slider is pulled to the bottom of the slider hole. When the motor is running a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com