Water absorption metal plate, radiating method and radiator

A metal sheet and water-absorbing technology, which is applied in the fields of water-absorbing metal sheets, heat dissipation methods and radiators, can solve the problems of no water absorption, complicated manufacturing process, and low water utilization rate, and achieve easy processing and manufacturing, improve heat dissipation effect, Facilitate the effect of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

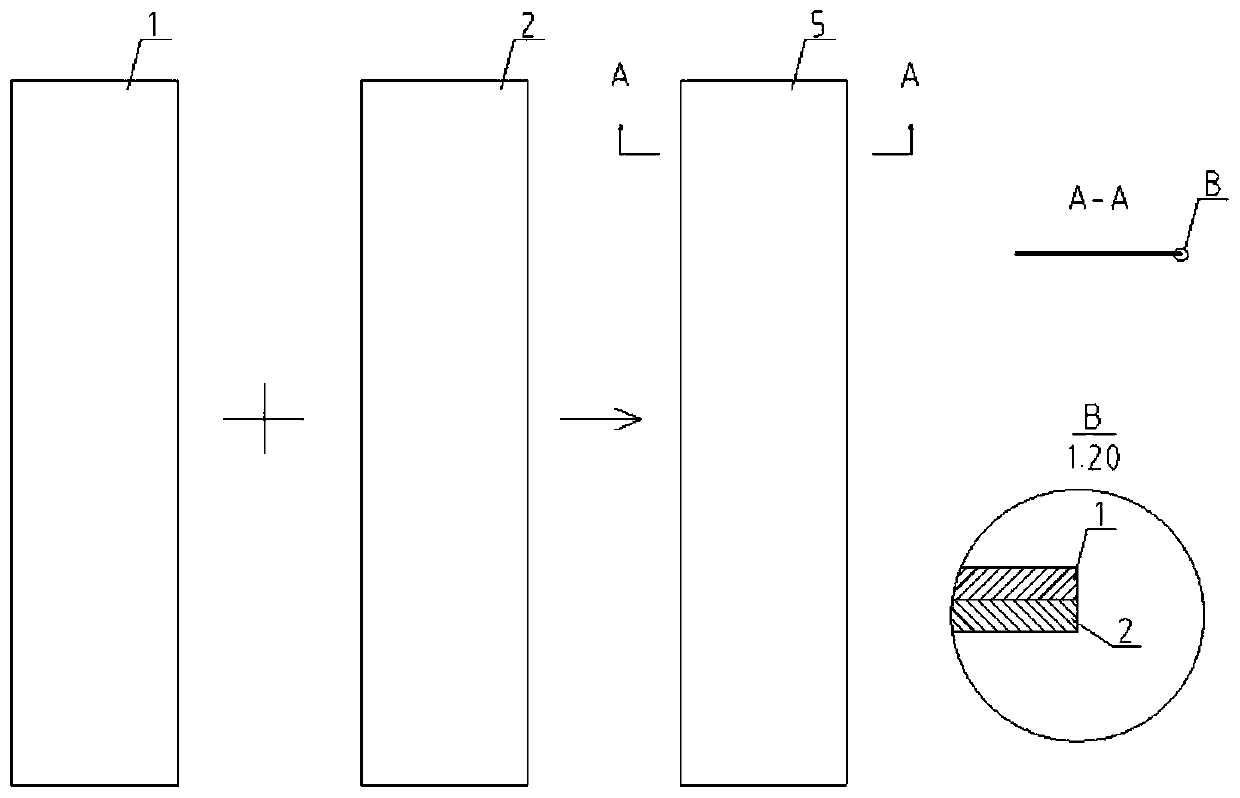

[0051] refer to figure 1 The water-absorbing metal sheet 5 provided in this embodiment consists of two layers of the same shape, the first metal sheet 1 and the second metal sheet 2, which overlap each other.

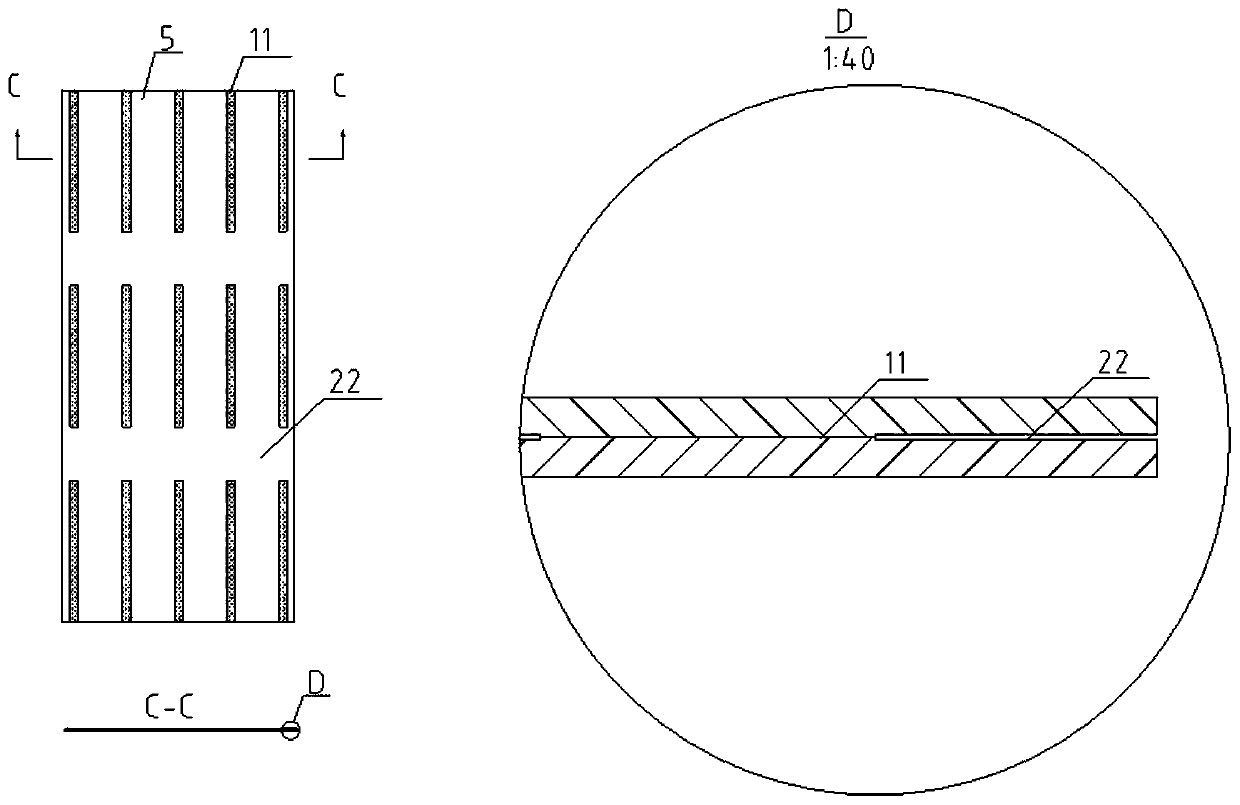

[0052] refer to figure 2, between the first metal sheet 1 and the second metal sheet 2, a contact area 11 and a gap area 22 are provided, and the contact area 11 between the metal sheets fixes the first metal sheet 1 and the second metal sheet 2 to each other; the contact area 11 is set Two layers of thinner metal sheets can be closely adhered to form a metal sheet with the same thickness as ordinary heat sinks from the outside, so as to obtain the same mechanical strength as ordinary heat sinks with the same thickness without increasing the cost of metal materials.

[0053] The gap area 22 between the first metal sheet 1 and the second metal sheet 2 forms fine, open capillary gaps. The interstitial area 22 is distributed in a network shape on the water-absorbing met...

Embodiment 2

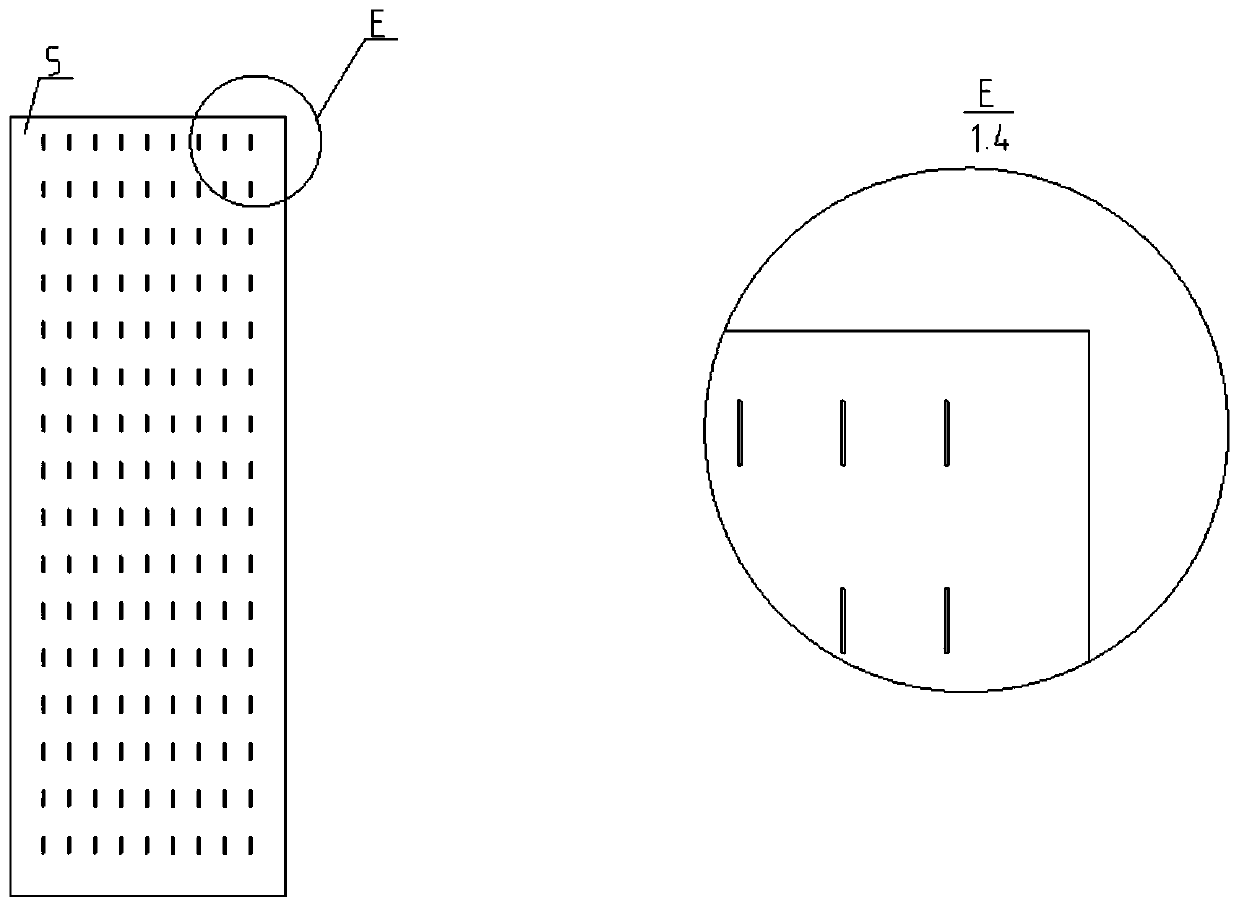

[0061] refer to image 3 , and the difference from Example 1 is that when the width of the two-layer heat sink with the same shape structure is wider, there are some cracks on the heat sink, and through these cracks, the moisture inside the water-absorbing metal sheet 5 is evaporated to obtain water. The latent heat of evaporation improves the cooling capacity of the heat sink.

Embodiment 3

[0063] refer to Figure 4 , the difference with embodiment 1 is that when the width of the two-layer heat sink with the same shape structure is wider, there are some shutters on the heat sink, and through these shutters, the moisture inside the water-absorbing metal sheet 5 is evaporated to obtain water. The latent heat of evaporation improves the cooling capacity of the heat sink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com