Roller ring for high-speed steel leveling machine special for rolling elevator guide rails and production method

A technology of elevator guide rail and high-speed steel, which is applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems such as affecting the rolling output and surface quality of elevator guide rail, high brittleness of roll ring, and increase of production cost, etc. It is easy to be widely popularized and used, with good wear resistance and red hardness, and the effect of small grinding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

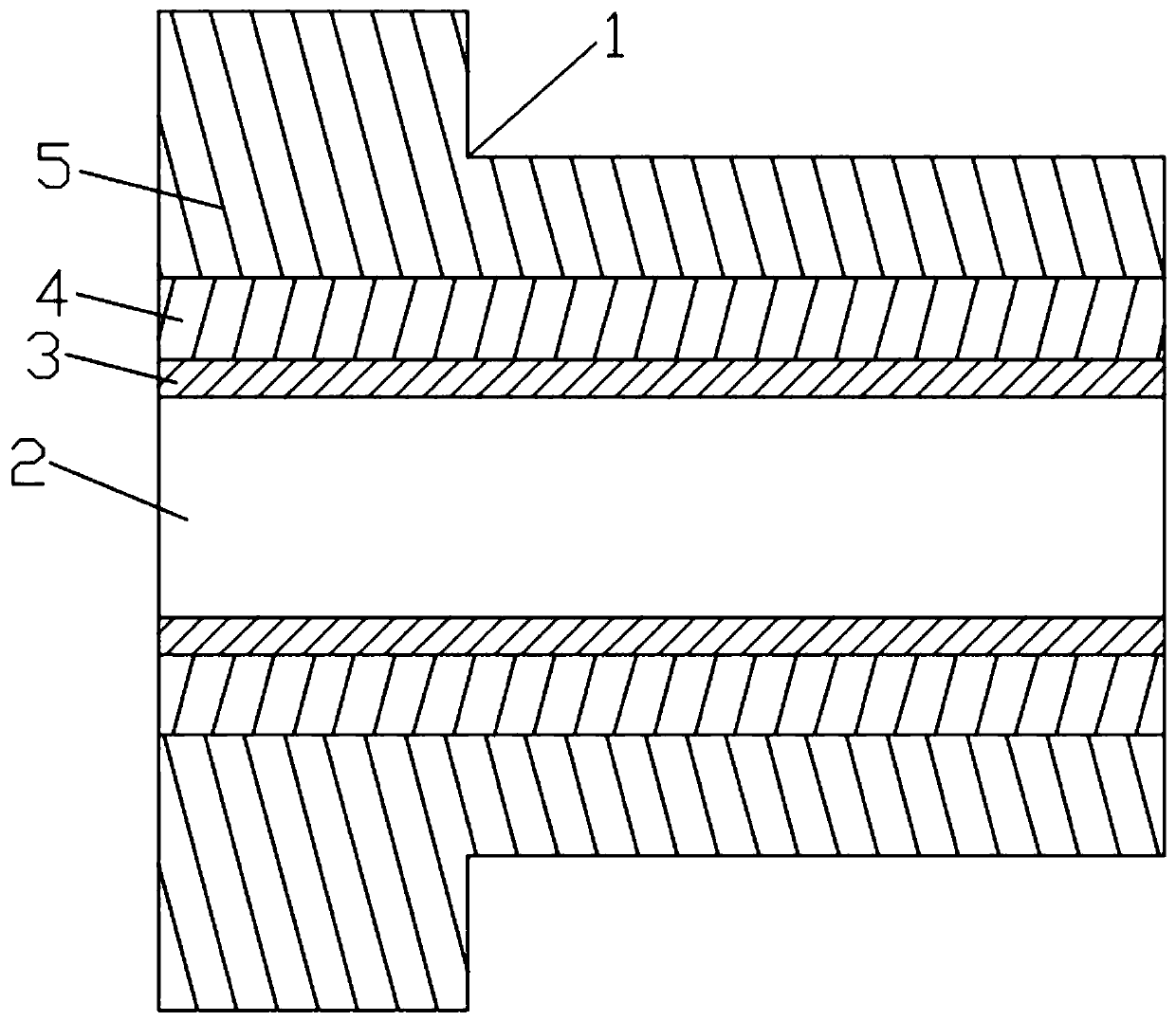

[0020] A method for producing roll rings for high-speed steel horizontal machines dedicated to rolling elevator guide rails, comprising the following production steps: S1, determining the chemical composition: working layer 5: C: 1.55%; Si: 0.50%; Mn: 0.35%; P: 0.01%; S: 0.0:1%; Cr: 5.00%; Ni: 0.55%; Mo: 3.35%; V: 5.00%; Nb: 0.20%; W: 1.30%; ; Si: 2.25%; Mn: 0.45%; P: 0.02%; S: 0.01%; Cr: 0.10%; Ni: 0.35%; Mg: 0.045%; Mn: 0.55%; P: 0.02%; S: 0.01%; Cr: 0.05%; Ni: 0.35%; Molten steel modifier, clean molten steel, remove impurity elements H, O, P and S; smelting middle layer 4 is after spheroidization treatment and inoculation of tap water, and then add 0.0% SiFe inoculant for secondary inoculation to improve the spheroidization level; inner layer After the smelting reaches the standard, add 2kg of CaBa inoculant during spheroidization to ensure the refinement of spheroidal graphite at 3um and roundness and distribution uniformity, and improve the tensile strength; the temperat...

Embodiment 2

[0022]A method for producing roller rings for high-speed steel horizontal machines specially used for rolling elevator guide rails, including the following production steps: S1, determining the chemical composition: working layer 5: C: 1.65%; Si: 0.80%; Mn: 0.45%; P: 0.0:2%; S: 0.02%; Cr: 5.50%; Ni: 1.00%; Mo: 3.65%; V: 5.50%; Nb: 1.30%; W: 3.20%; ; Si: 2.65%; Mn: 0.60%; P: 0.0:4%; S: 0.02%; Cr: 0.13%; Ni: 0.65%; %; Mn: 0.65%; P: 0.04%; S: 0.02%; Cr: 0.12%; Ni: 0.45%; Mg: 0.065%; Basis weight rare earth molten steel modifier, clean molten steel, remove impurity elements H, O, P and S; smelting middle layer 4 is after spheroidization treatment and inoculation of tap water, add 0.08% SiFe inoculant for secondary inoculation to improve the spheroidization level ; After the inner layer smelting reaches the standard, add 2.58kg of CaBa inoculant during spheroidization to ensure the refinement of spheroidal graphite at 3.5um, roundness and uniform distribution, and improve the tens...

Embodiment 3

[0024] A method for producing roller rings for high-speed steel horizontal machines specially used for rolling elevator guide rails, comprising the following production steps: S1, determining the chemical composition: working layer 5: C: 1.75%; Si: 1.00%; Mn: 0.55%; P: 0.03%; S: 0.025%; Cr: 6.00%; Ni: 1.55%; Mo: 3.95%; V: 6.00%; Nb: 1.50%; : 2.75%; Mn: 0.8%; P: 0.05%; S: 0.03%; Cr: 0.15%; Ni: 0.85%; M: 0.045%; inner layer 3: C: 3.35%; 0.75%; P: 0.05%; S: 0.03%; Cr: 0.15%; Ni: 0.55%; agent, clean molten steel, and remove impurity elements H, O, P, and S; the smelting middle layer 4 is after spheroidization treatment and inoculation of tap water, and 0.10% SiFe inoculant is added for secondary inoculation to improve the spheroidization level; the inner layer smelting reaches the standard Finally, add 3kg of CaBa inoculant during spheroidization to ensure the refinement of spheroidal graphite at 4um, roundness and distribution uniformity, and improve tensile strength; the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com