Sliding block type section full-supporting core rod structure with diameter changed through ratchet wheel inverse stop rotation

A slider-type, support core technology, applied in the field of fully-supported mandrel structure with slider-type cross-section, can solve the problems of uneven wear of mandrel, shortened service life, difficult assembly and disassembly of ball joints, etc., and achieves fast adjustment process Convenience, improve efficiency and reliability, ensure the effect of supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

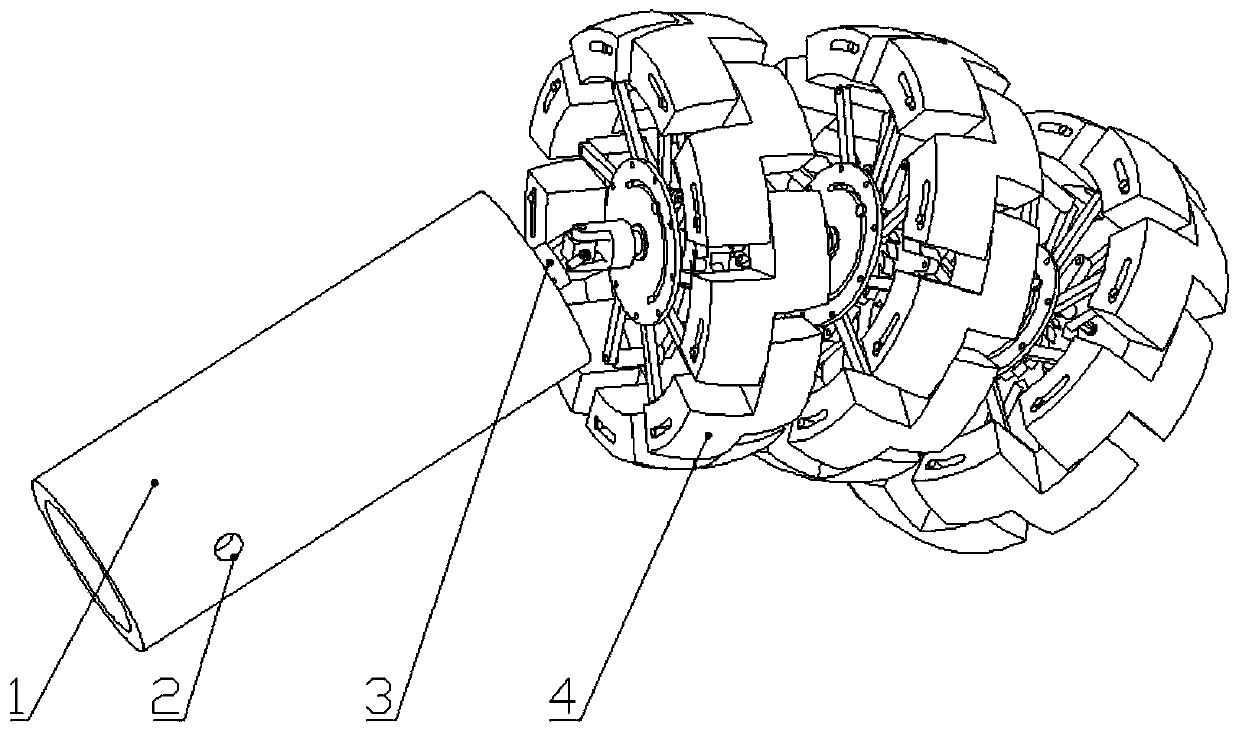

[0033] Such as figure 1 As shown, the present invention includes a straight handle 1 and a single or multiple mandrel joints 4, between the straight handle 1 and the mandrel joints 4, and between two adjacent mandrel joints 4 through quick-release universal joints 3 connected; the straight handle 1 is provided with a straight handle positioning pin hole 2, when the present invention is used in a numerically controlled pipe bender, the straight handle positioning pin hole 2 can cooperate with another positioning pin shaft to limit the straight handle during the bending process. Possible axial rotation of handle 1.

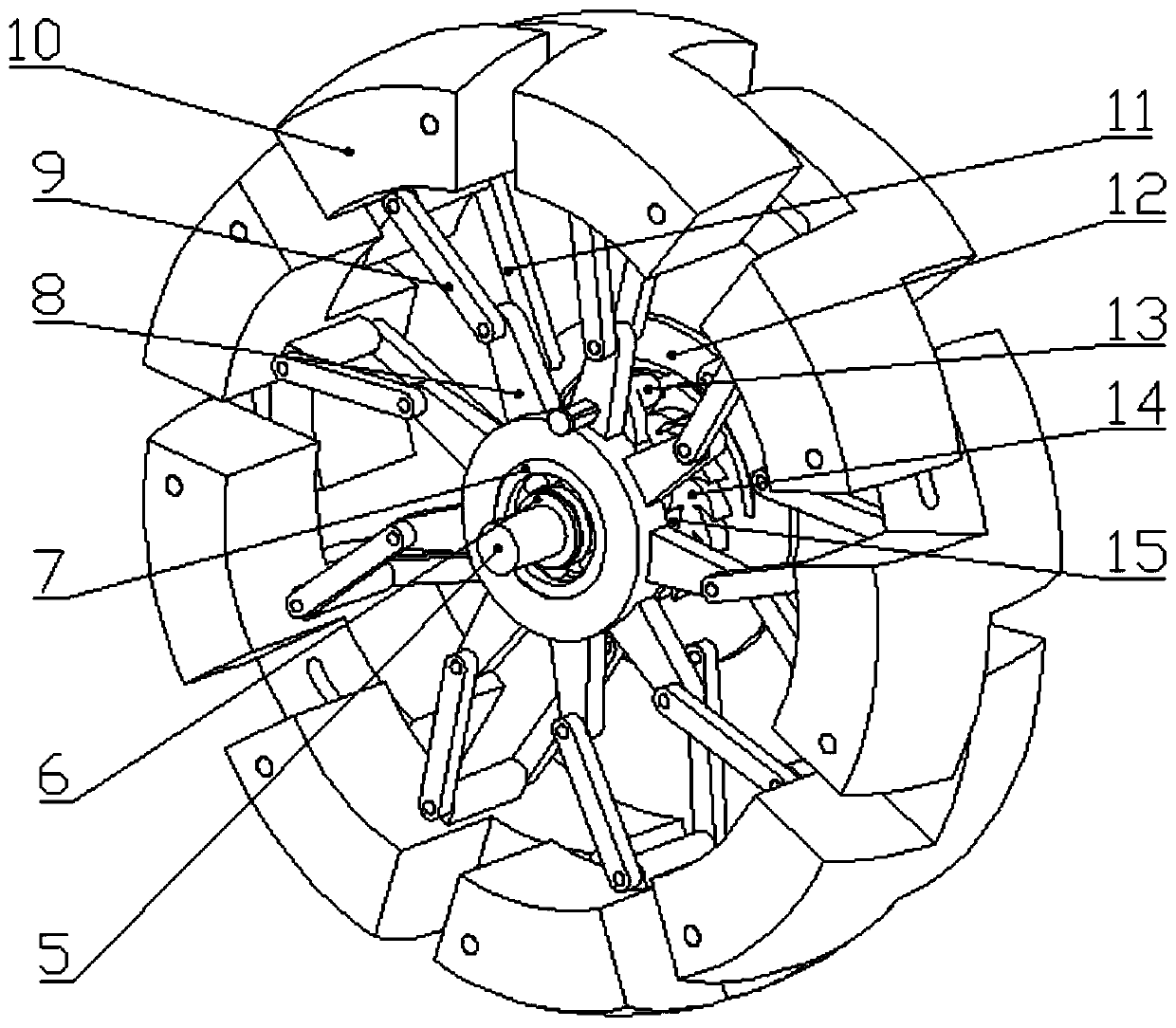

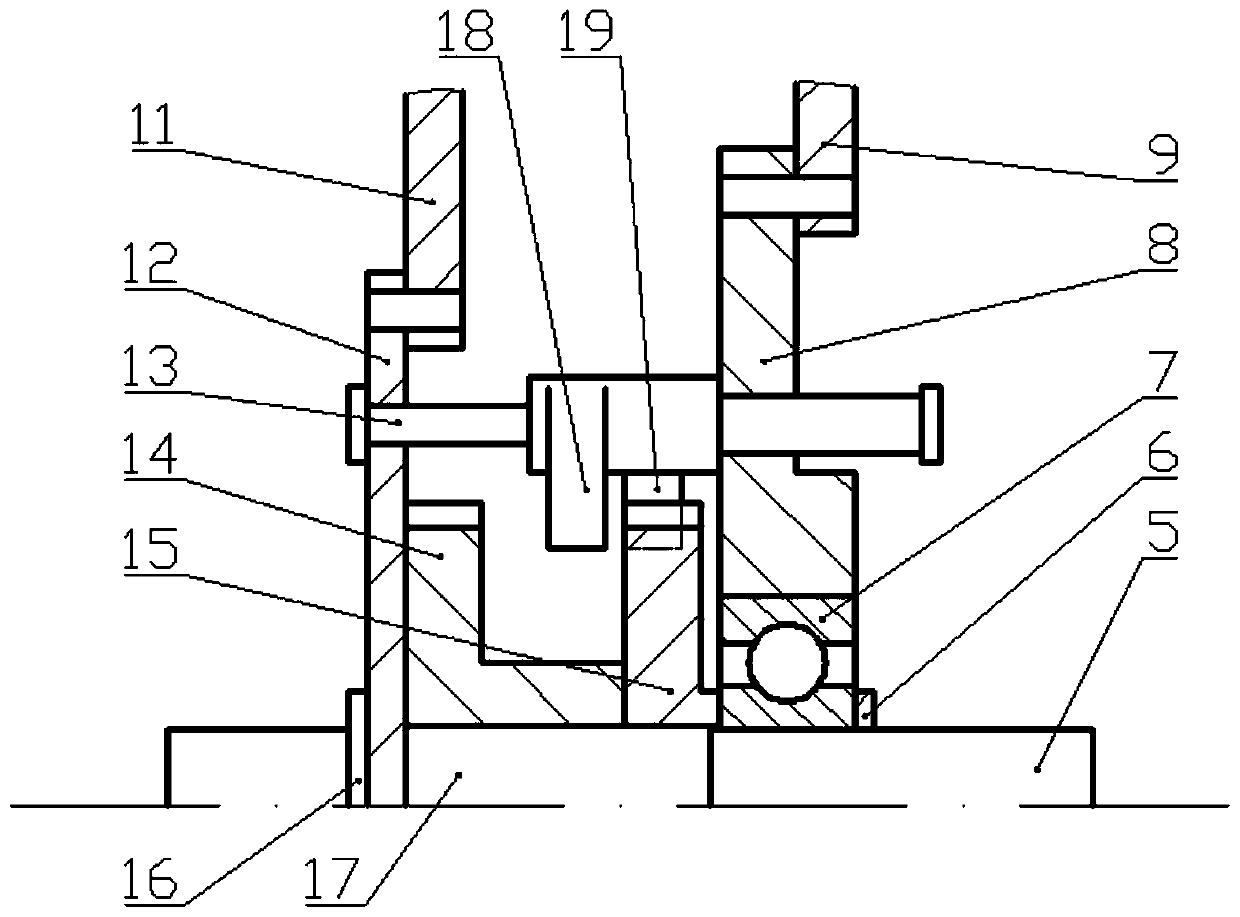

[0034] Such as figure 2 and image 3As shown, the inside of the mandrel joint 4 is a shaft system structure, including a rotating shaft 5, a bearing 7, a ratchet device, a connecting rod mounting plate 12 and a slider component 10. The ratchet dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com