How to use fiber cement ridge tile automatic cutting machine

A technology of fiber cement and cutting machine, applied in the direction of work accessories, manufacturing tools, stone processing tools, etc., can solve the problems of workers' randomness, high labor intensity, and irregular products, and achieve simple use, high degree of automation, and cutting high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

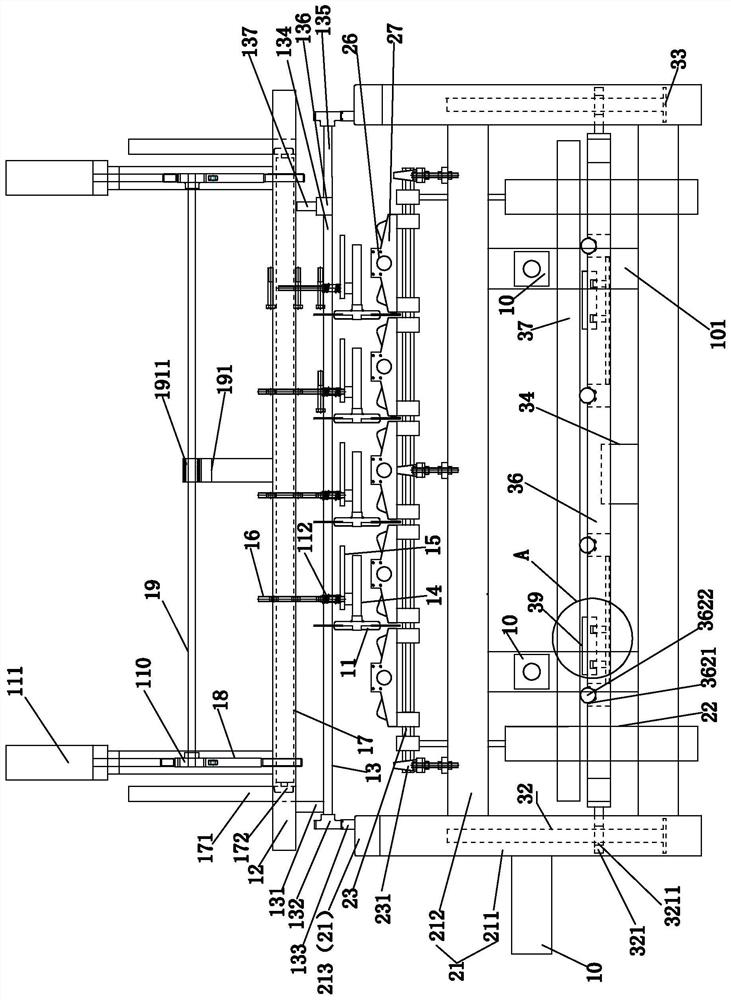

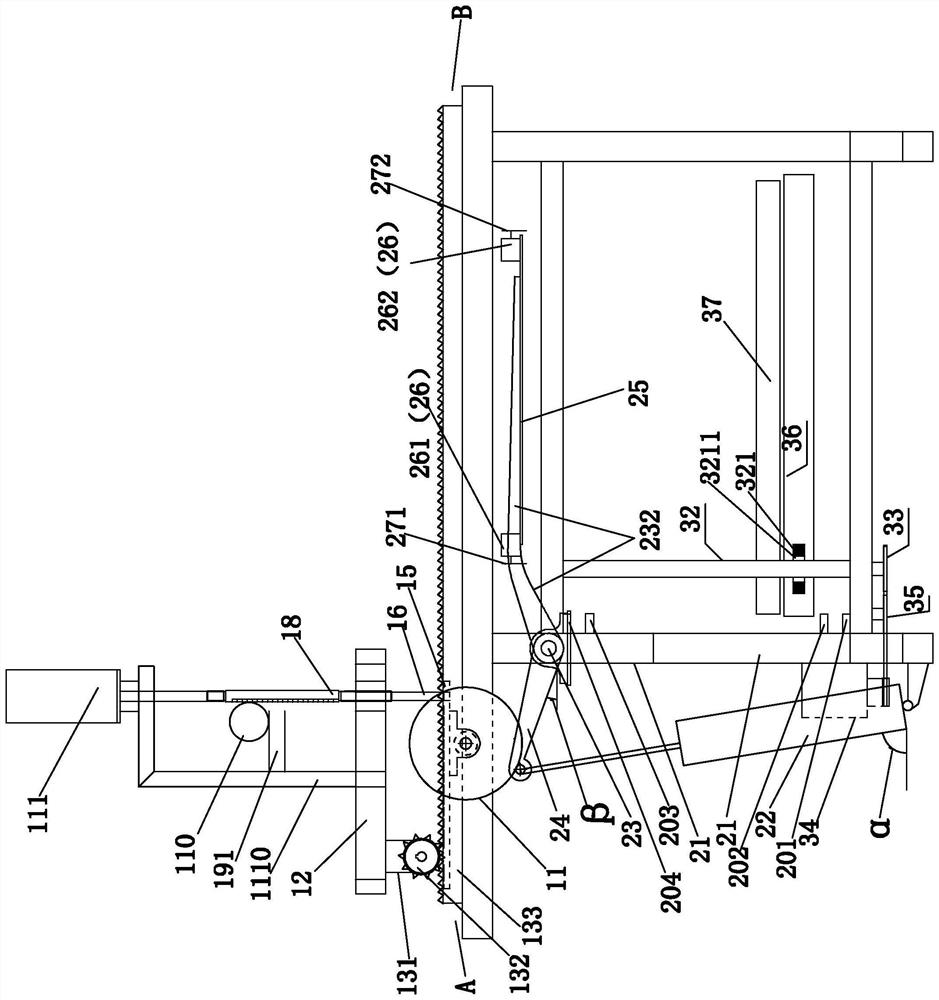

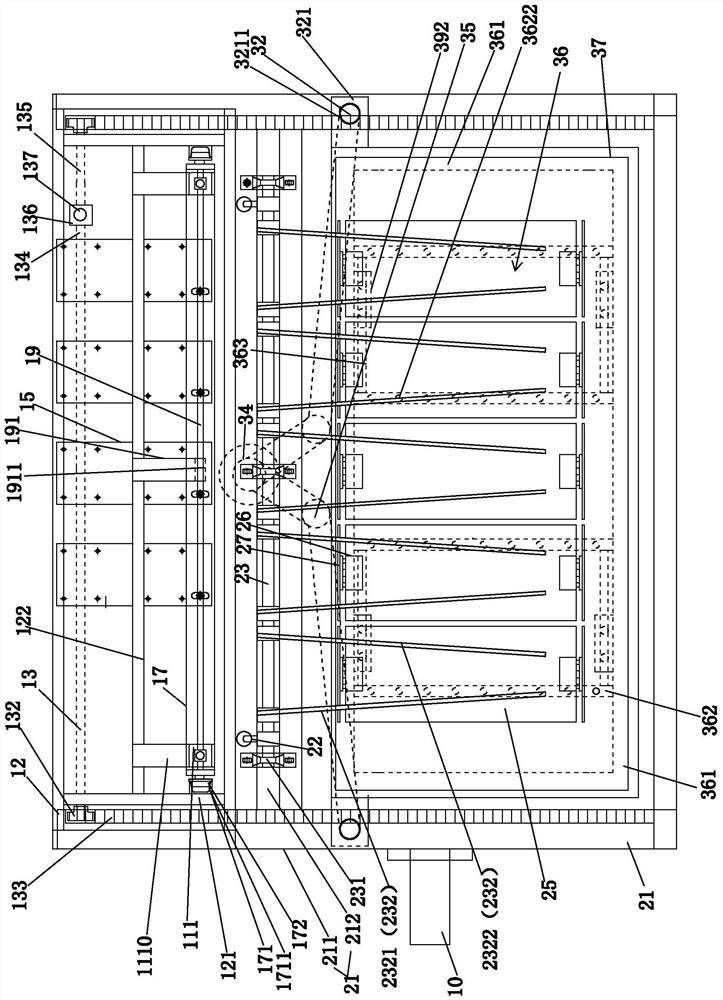

[0020] Such as Figure 1-5 The use method of the described a kind of fiber cement ridge tile automatic cutting machine: comprises the following steps:

[0021] 1) Before the start-up operation, the lifting platform is at the lower limit switch at the lower end of the trapezoidal screw rod, the cylinder of the overturning pressure plate retracts, the piston rod of the overturning pressure plate cylinder drives the overturning arm to move upward, the overturning arm drives the central shaft to rotate, and the central shaft drives the pressure plate upward Movement, when the pressure plate is lifted, the clamping cylinder piston rod outputs, driving the clamping splint to release;

[0022] 2) The knife lifting frame is located at the A end. The DC electromagnet is powered off and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com