Concrete and metal structure combined type foundation pit supporting system

A technology of support system and metal structure, applied in infrastructure engineering, excavation, construction, etc., can solve the problem of unclear connection force transmission of concrete crown beam or waist beam, difficult to guarantee the quality of concrete crown beam or waist beam, and lack of assembly of support system Convenience and other issues, to achieve the effect of improving construction efficiency, removing potential safety hazards, and increasing construction convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

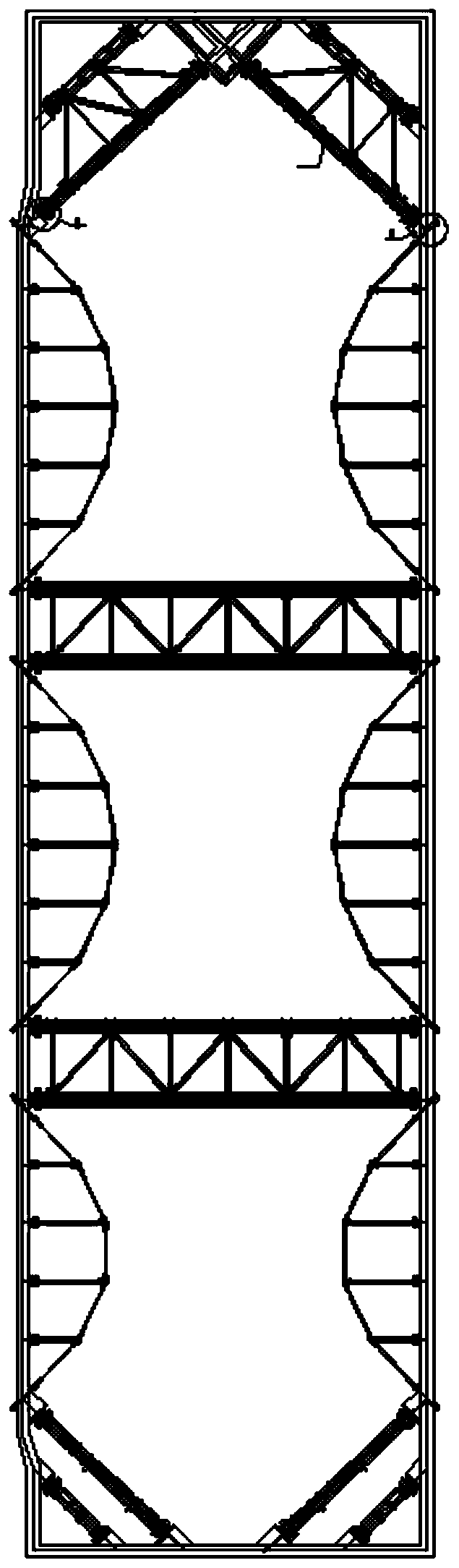

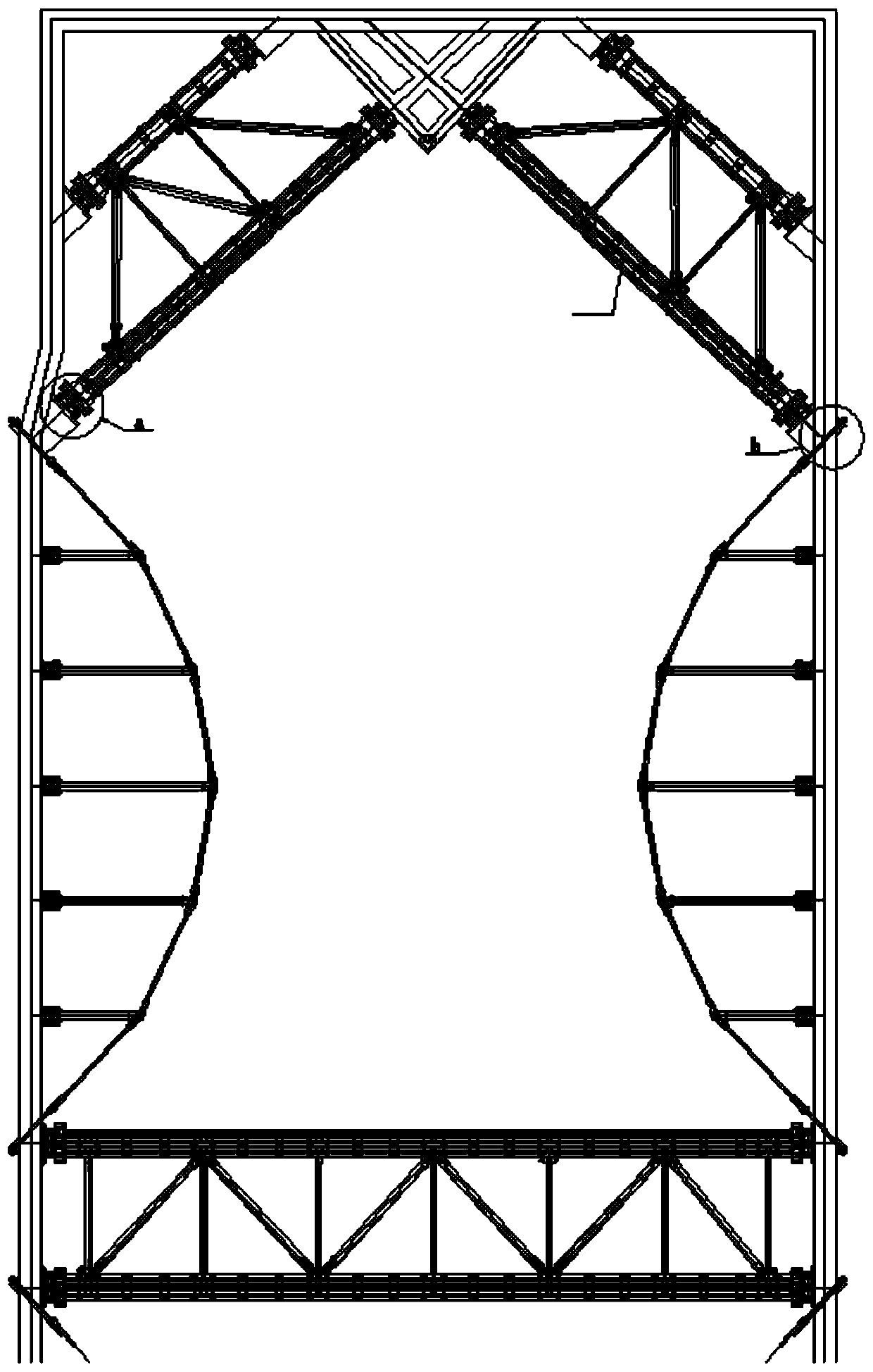

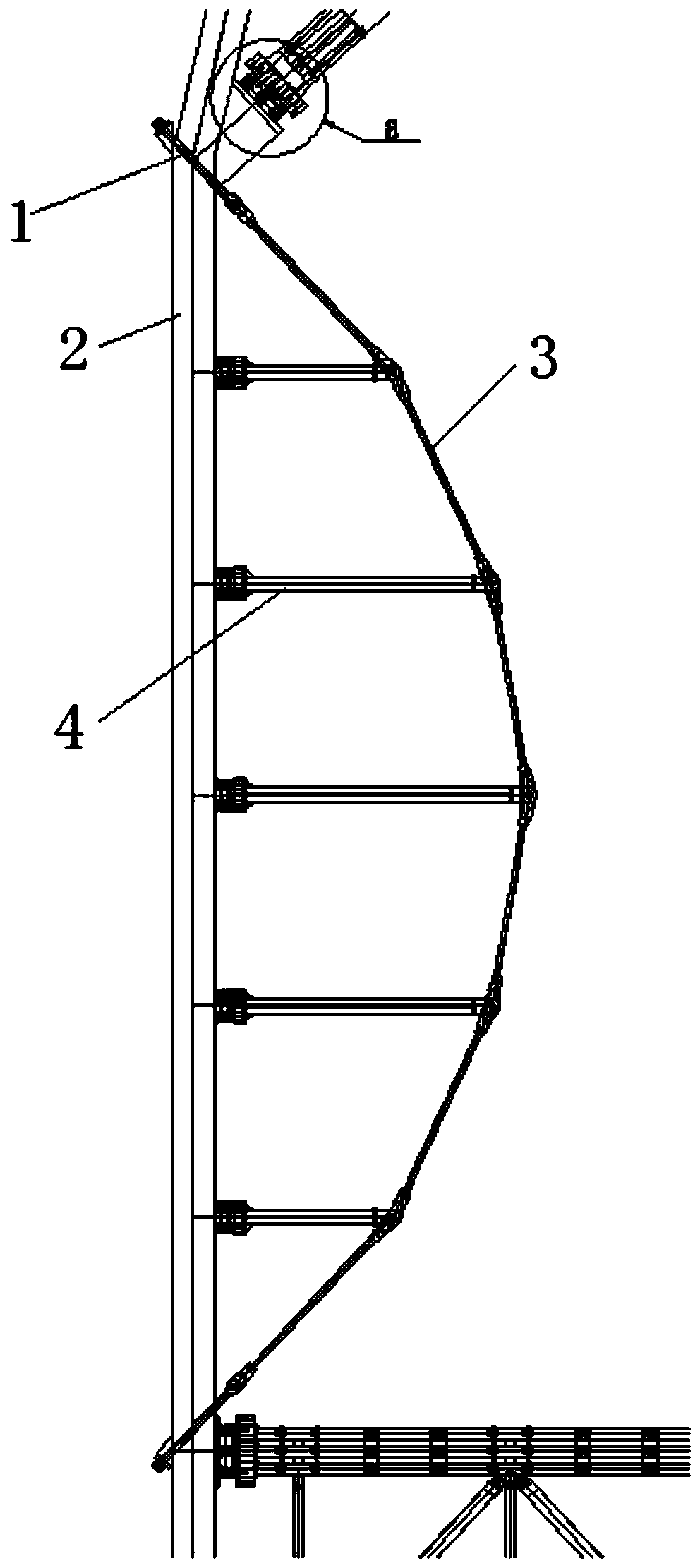

[0034] see Figure 1-3 , a concrete and metal structure combined foundation pit support system, comprising a concrete beam, a truss support system, and a combined string beam system; the concrete beam is arranged on the inner wall of the foundation pit; the end tie rods of the string beam of the combined string beam system are embedded in the The concrete beams are integrally and fixedly connected with the concrete beams; the webs 4 of the tension beams act on the concrete beams; the truss support system acts on the concrete beams.

[0035] see image 3 , an active prestress adjusting device is provided on the web bar 4 of the stretched beam.

[0036] continue to see image 3 , a pair of end pull rods 1 are also provided with a plurality of intermediate pull rods, and the intermediate pull rods are directly hingedly connected.

[0037] contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com