Lightning protection system of wind power blade

A technology of wind power blade and lightning protection system, which is applied to wind power generation, wind turbines in the same direction as the wind, wind turbines, etc., can solve the problems of failure of lightning protection system, failure of metal mesh to conduct current, damage to metal mesh, etc. Increase the connection area, ensure that it will not fall off at will, and improve the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

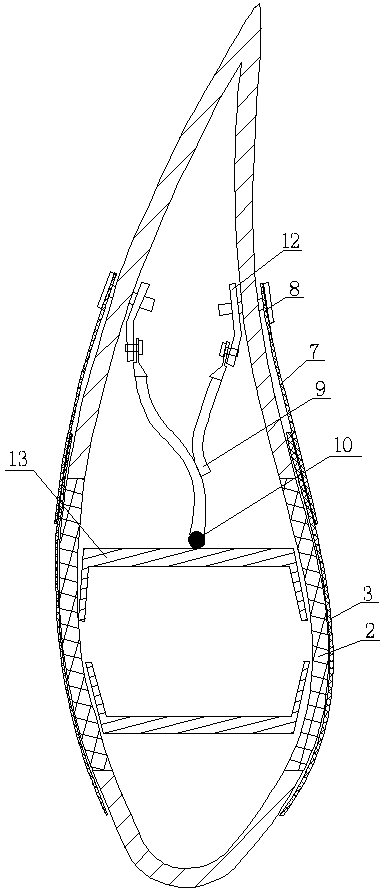

[0030] The core of the present invention is to provide a lightning protection system for wind turbine blades. The lightning protection system in the present invention can also achieve good results when applied to wind turbine blades containing carbon fiber main beams. Of course, the lightning protection system can also be used In wind turbine blades with main beams made of other materials (such as two glass fiber main beams, one glass fiber main beam and one carbon fiber main beam). After the lightning protection system is struck by lightning, it can divert the metal mesh and the cable through double diversion channels, avoiding the problem of the overall failure of the lightning protection system caused by the lightning strike of the metal mesh, and can more comprehensively guarantee the operation safety of the blade.

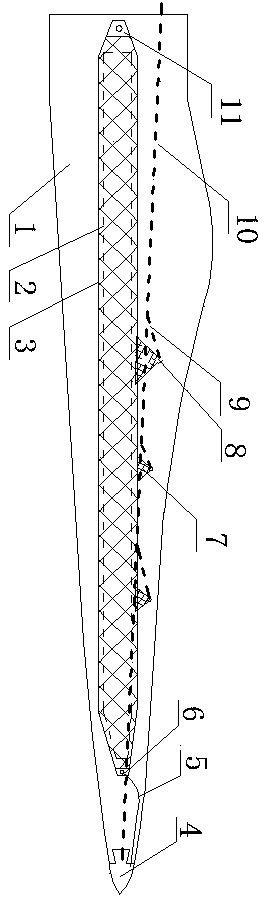

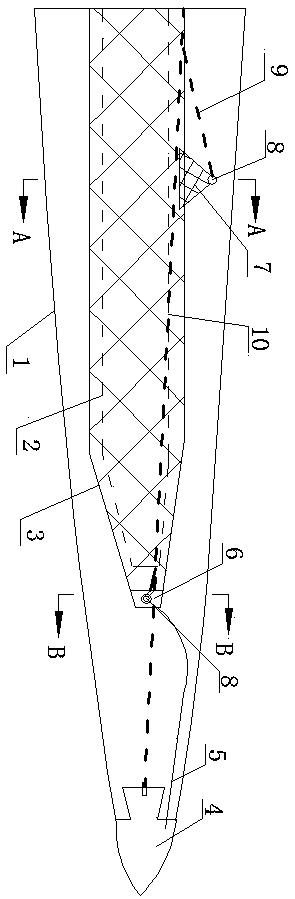

[0031] Such as Figure 1-5 As shown, the lightning protection system for wind turbine blades shown in the present invention mainly includes a metal mesh I 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com