Single element multilayer infrared high-reflection film and preparation method thereof

A high-reflection film, single-element technology, used in coatings, metal material coating processes, ion implantation plating, etc., can solve the problems of corrosion resistance of thin-film components, and achieve good bonding performance, wide application range, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

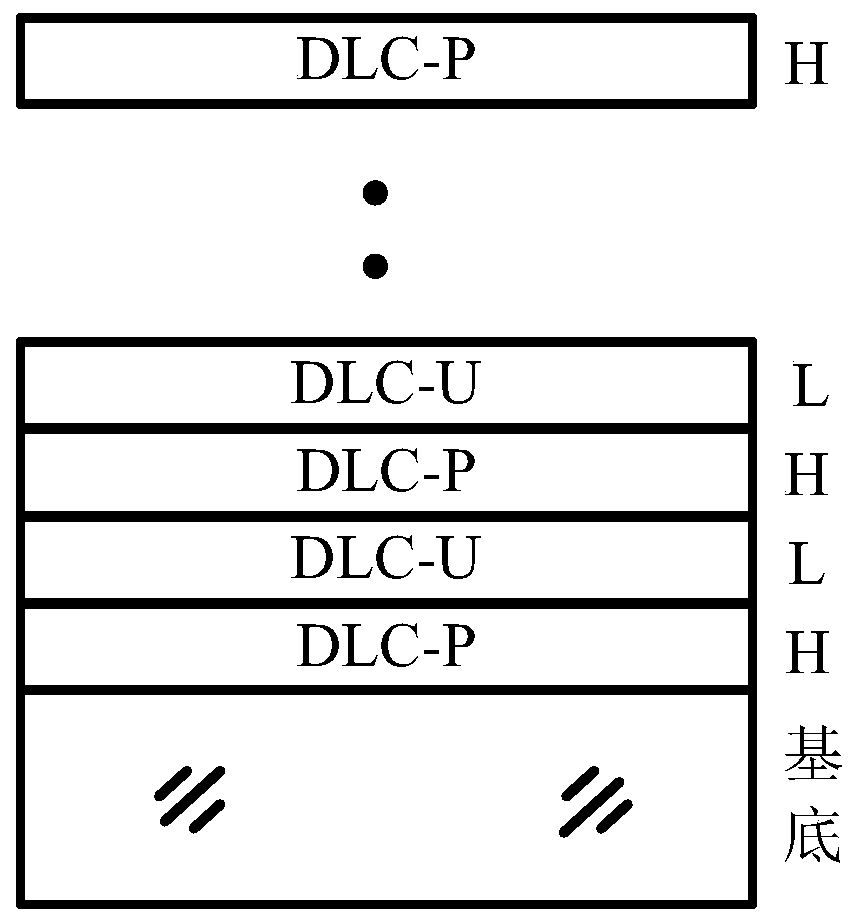

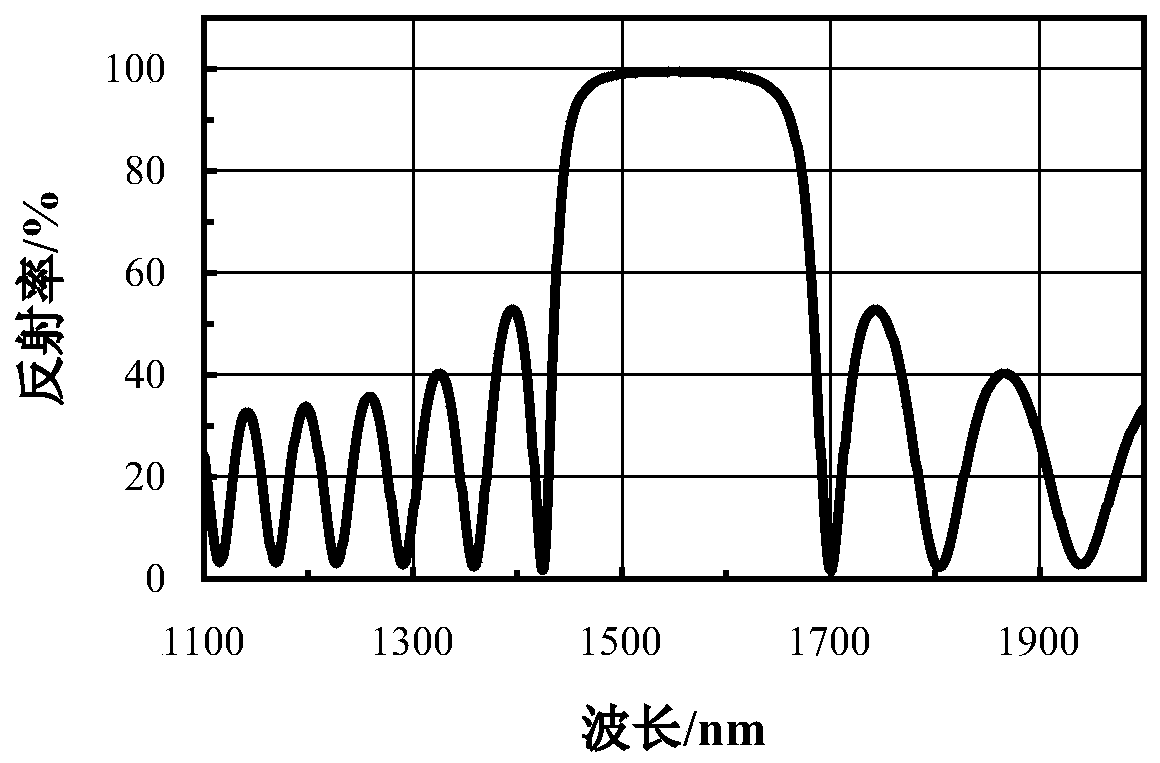

[0029] see figure 1 , a single-element multi-layer infrared high-reflection film is characterized in that it is composed of a multi-layer DLC film coated with a substrate and a graphite target, and the basic structure of the film system is: S / (HL) x H / A, where S is the Si substrate, H is the DLC film with high refractive index, L is the DLC film with low refractive index, x is the cycle number of repeated plating of H and L, and A is air.

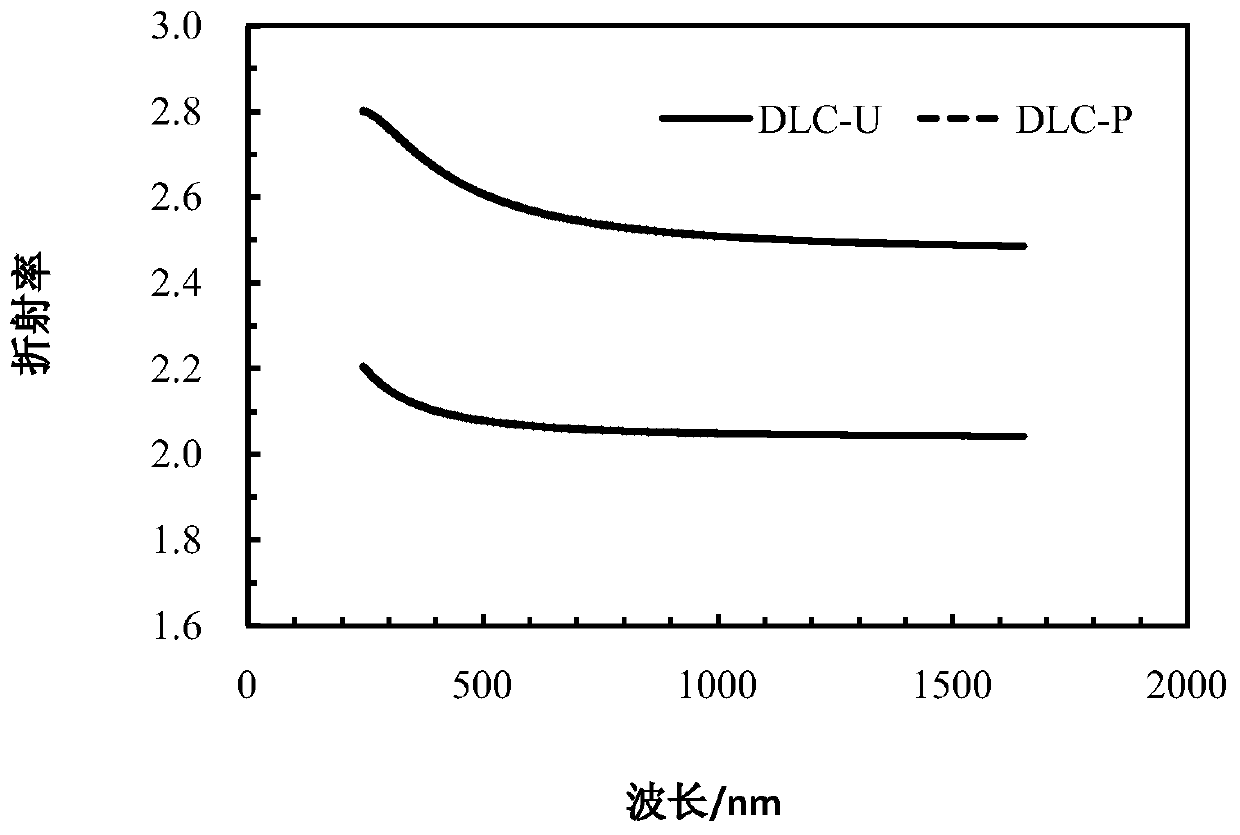

[0030] It can be seen from the figure that the high-reflection film is composed of two materials with different refractive indices, H and L. Among them, the DLC film plated by pulsed arc technology is recorded as DLC-P, and the film plated by unbalanced magnetron sputtering technology is denoted as DLC-P. The DLC film is denoted as DLC-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com