Method for calculating adsorption quantities of different aperture surfaces of shale organic matter

A pore surface and organic matter technology, applied in the field of shale gas exploration, can solve the problems of not being able to reflect the real adsorption of methane well, and achieve the effect of good promotion and application value, simple method and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

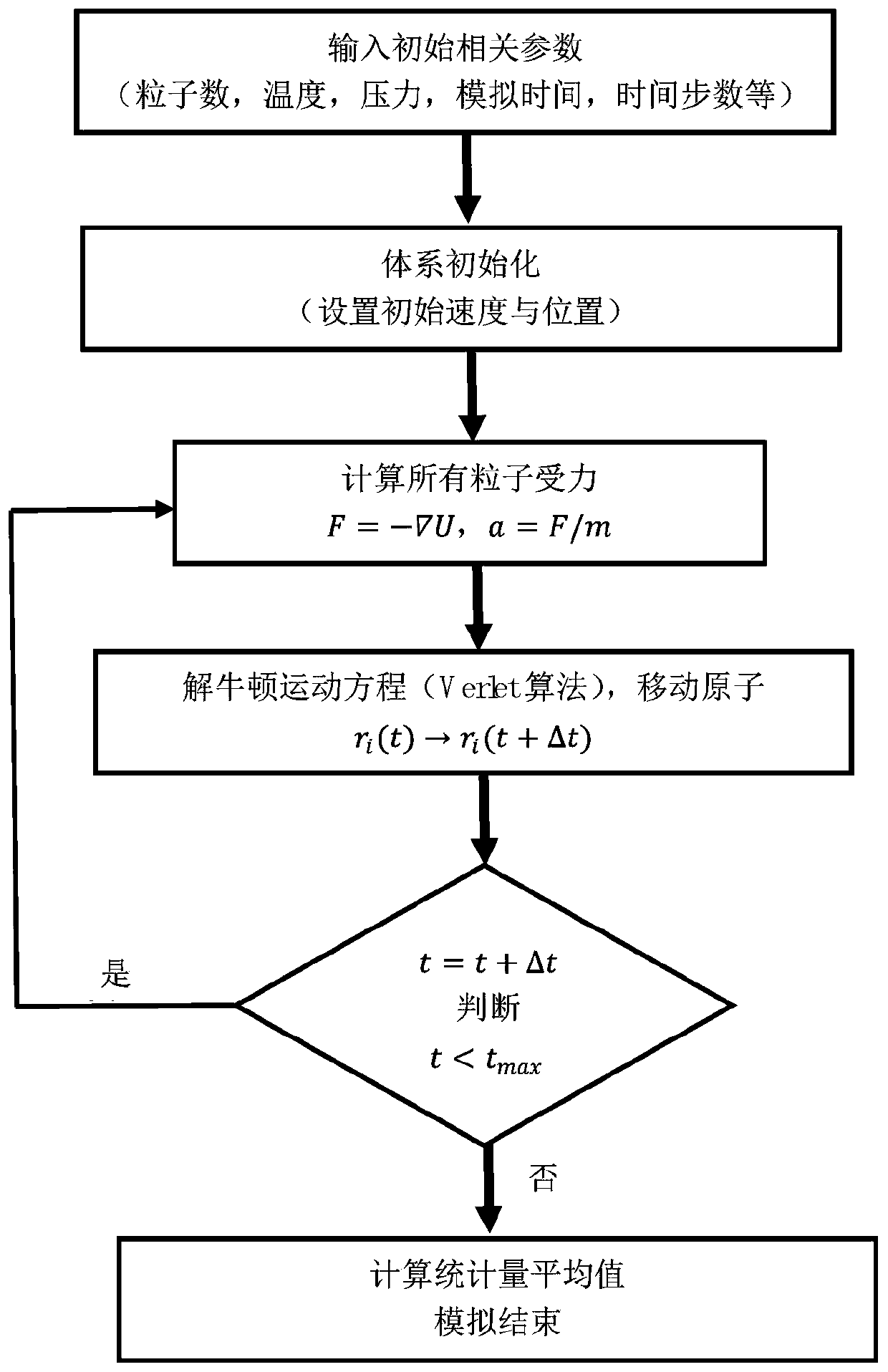

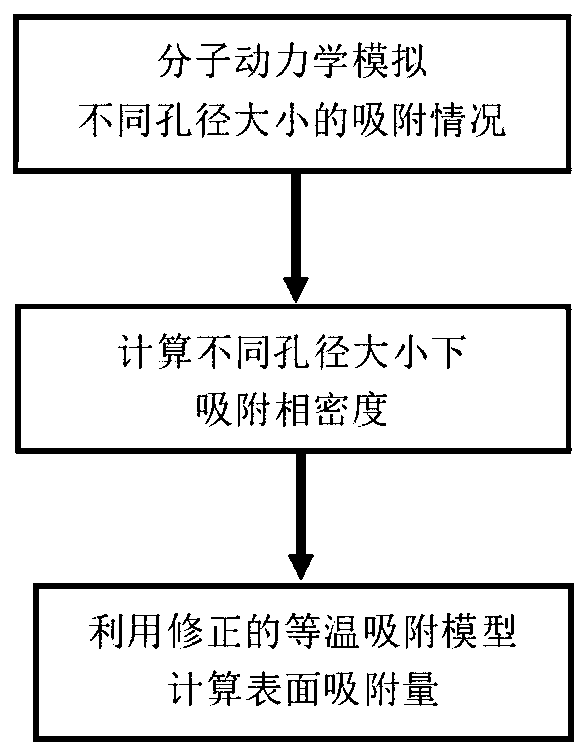

[0055] A method for calculating the surface adsorption of shale organic matter with different pore sizes, such as figure 2 Shown is the flowchart of the method of the present invention, and when the method is tested in a certain oil field, the concrete steps are as follows:

[0056] (1) Build a model

[0057] Use graphite to construct the interlayer structure of graphene to replace the interlayer structure of organic matter, use three layers of graphene sheets as the solid wall of organic nanopores, and ensure that the parallel distance between adjacent two layers is 0.335nm. Then, the methane configuration that has been constructed in the MaterialsStudio software package is imported into the established organic matter model for subsequent adsorption simulations.

[0058] (2) Simulation processing

[0059] Such as figure 1 Shown is the flow chart of the molecular dynamics simulation method. The Smart algorithm is used to minimize the energy of the molecular system, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com