Assembling method of miniaturized printed board

An assembly method and technology for printed boards, which are applied in the directions of printed circuits, printed circuit components, and electrical connection printed components, can solve the problems of difficult assembly and low integration of small printed boards, and achieve space saving, easy operation, and reduction in size. The effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

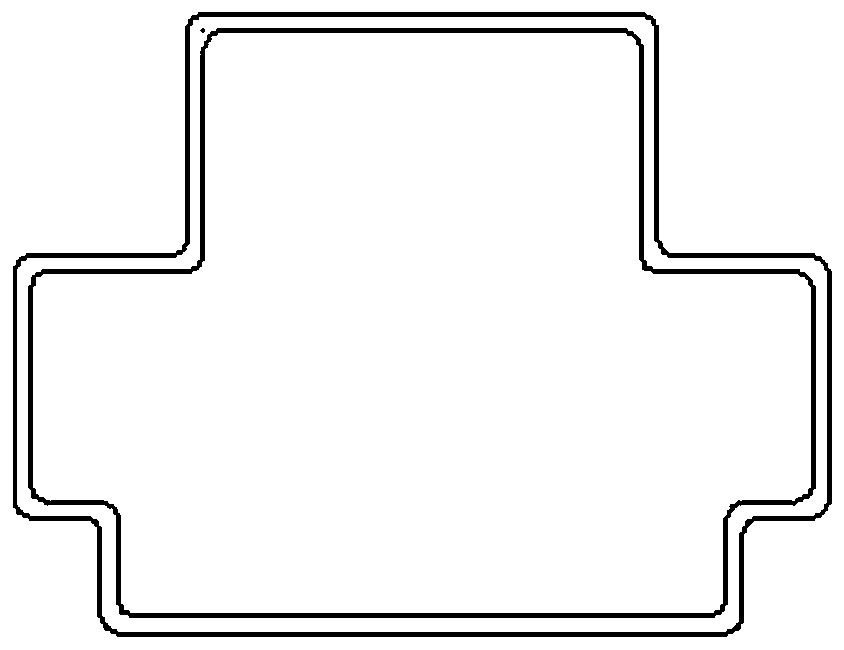

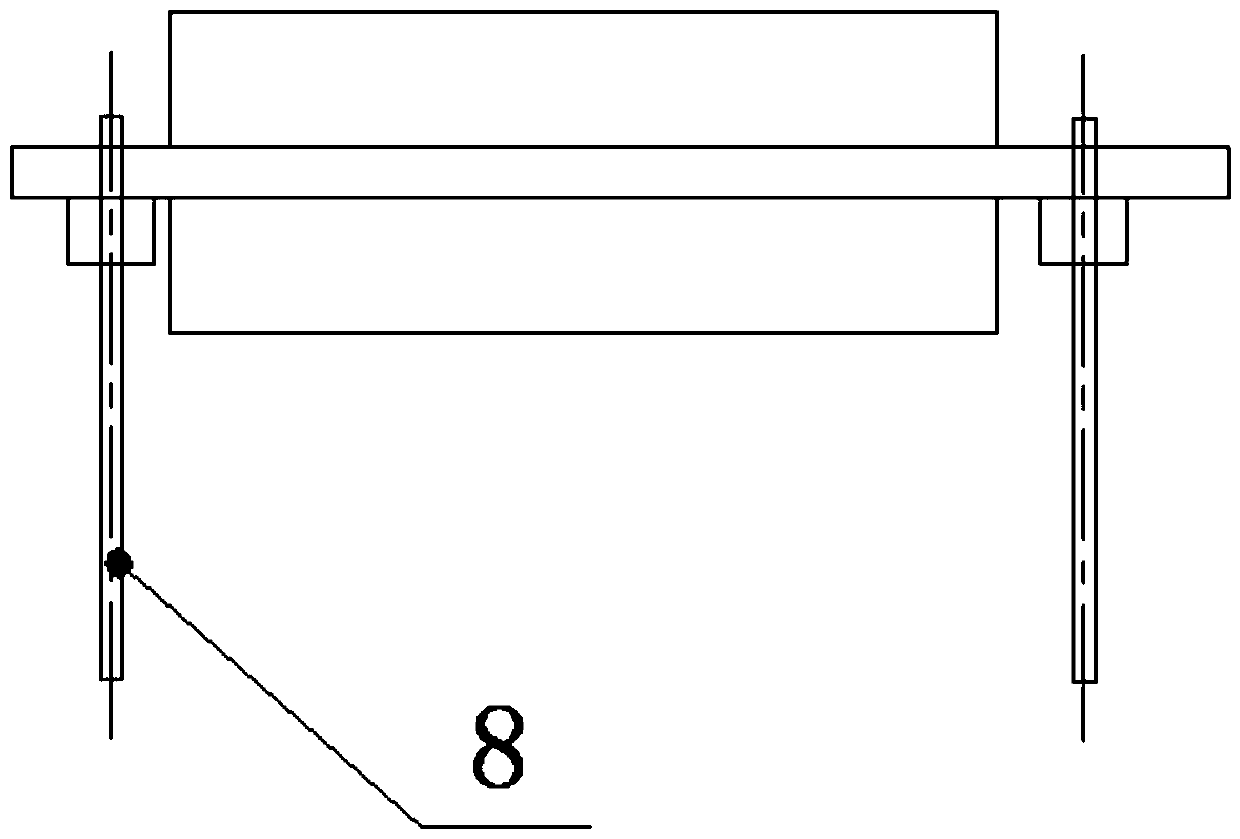

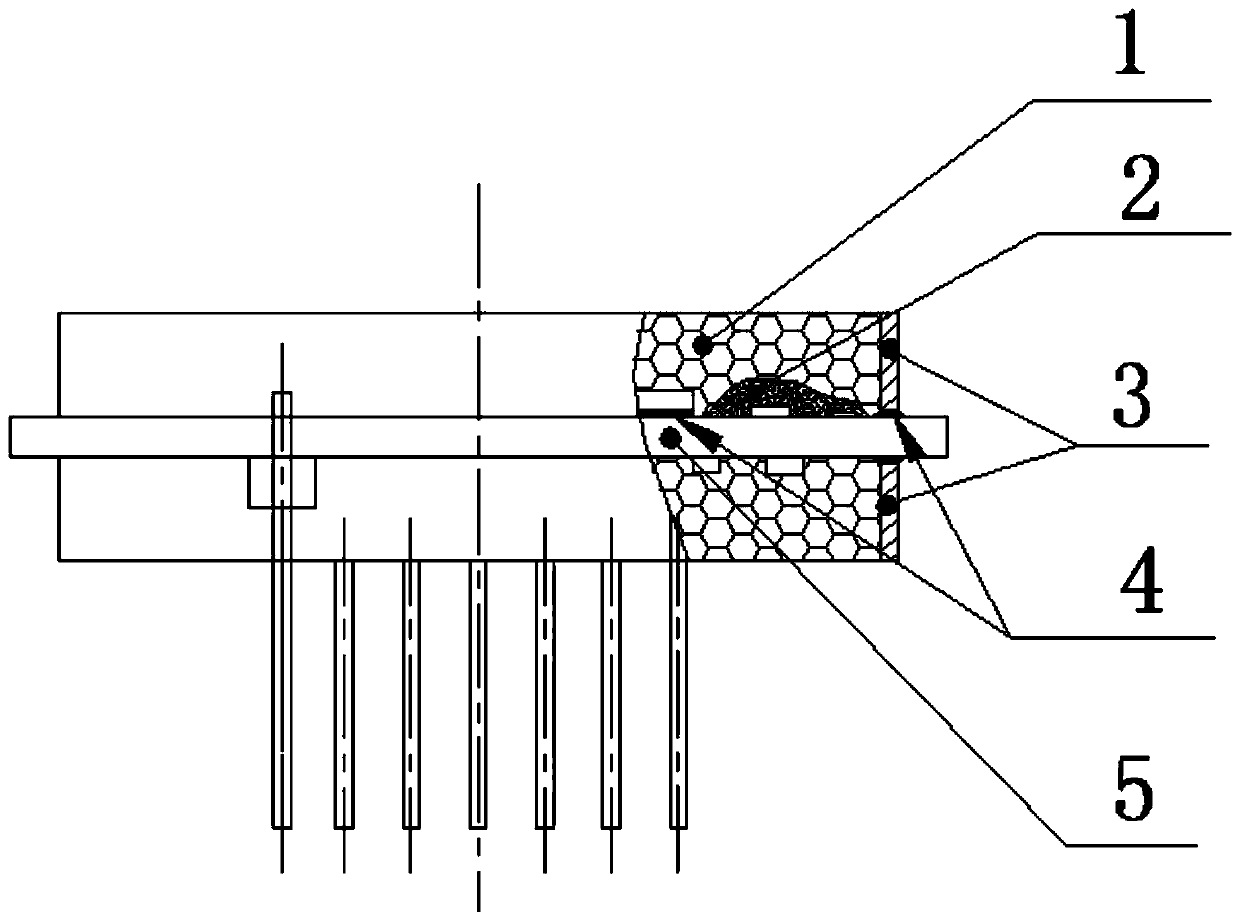

[0033] Such as figure 1 As shown in -4, what is adopted in the present invention is the miniaturized assembly technology of the printed board, which adopts the enclosing frame bonding (or welding) on the PCB board 5, and then potting and encapsulating the technology for encapsulation. The PCB board 5 is a circular structure with three equally divided large mounting holes 9 on the edge for installing and fixing the PCB board 5 , the wiring area is irregular and the space is narrow. The outer lead pin 8 is drawn out by pin soldering. In the circuit on the PCB board 5, the resistors and power resistors that need active trimming are printed with a ceramic substrate thick film, which can be divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com