Laser systems utilizing cellular-core optical fibers for beam shaping

A laser system and honeycomb core technology, applied in the field of laser systems, can solve the problems of damage to the optical components of the laser system, time-consuming, expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

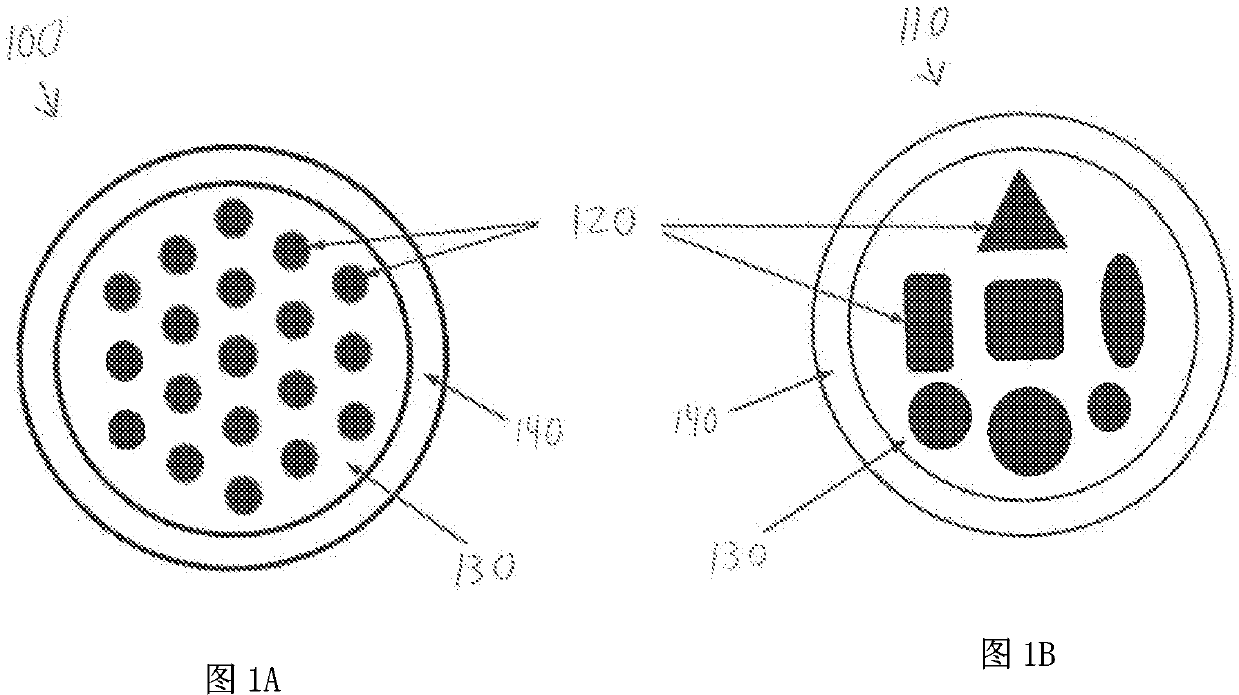

[0043] Figures 1A and 1B Two different exemplary honeycomb core fibers 100, 110 that may be used in various embodiments according to the invention are depicted. As shown, each honeycomb core fiber has a plurality of different core regions 120, each core region having a refractive index (e.g., a refractive index n 0 ). (Although all core regions 120 are described as having the same refractive index in this example, embodiments of the invention include implementations in which one or more core regions 120 have a different refractive index than the other core regions; These indices of refraction are generally greater than those of the intercore cladding region and / or the outer cladding.) While honeycomb core fibers 100, 110 are depicted with various shapes and numbers of core regions 120 (e.g., for fiber 100, its transverse The cross-section is substantially circular; for fibers 110, which have different shapes (e.g., square, rectangular, triangular, oval, circular, etc.)), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com