Moisturizing and repairing face cream and preparation method thereof

A face cream and raw material technology, applied in the field of skin care products, can solve the problem of high energy consumption, achieve the effect of improving skin sensitivity, improving anti-dehydration ability, and reducing greasy feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

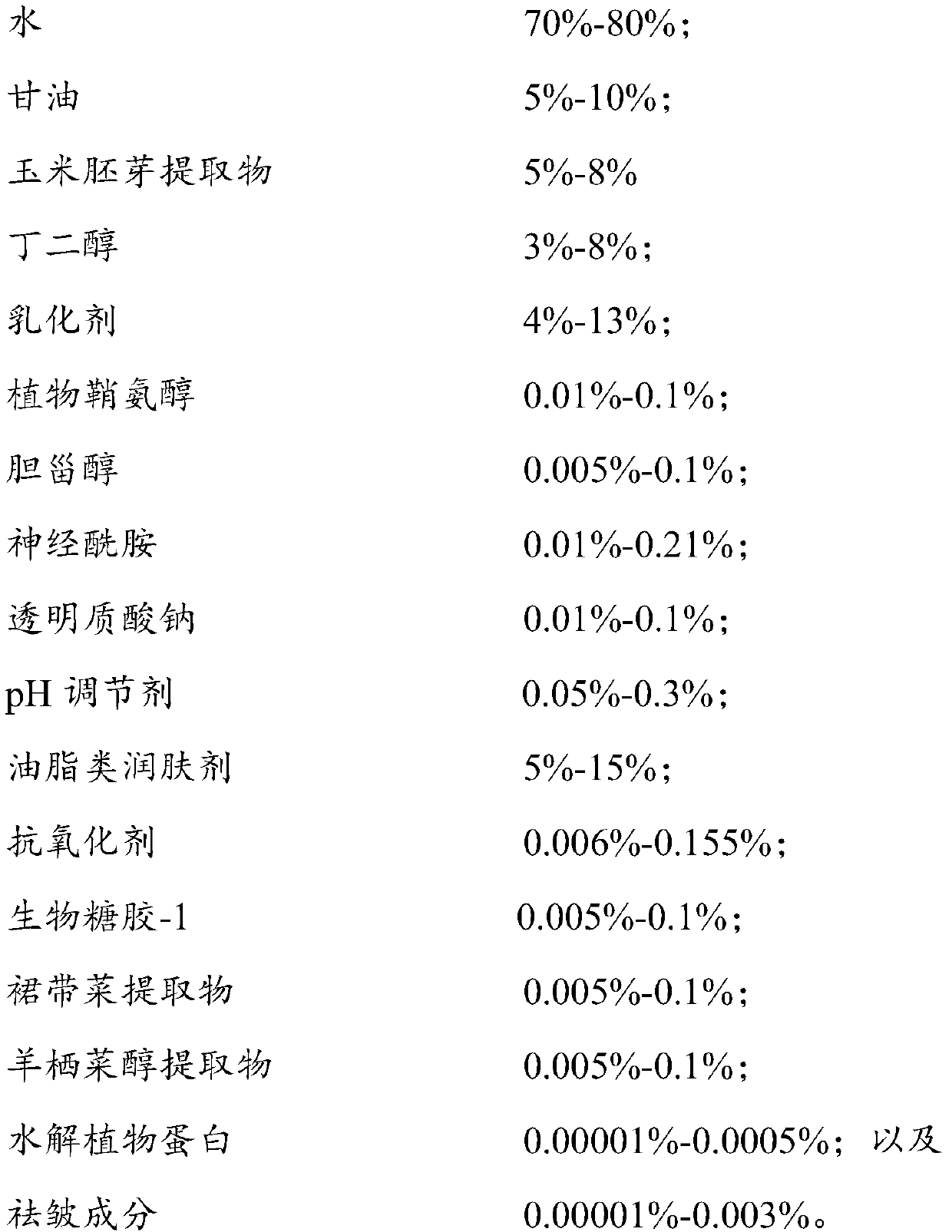

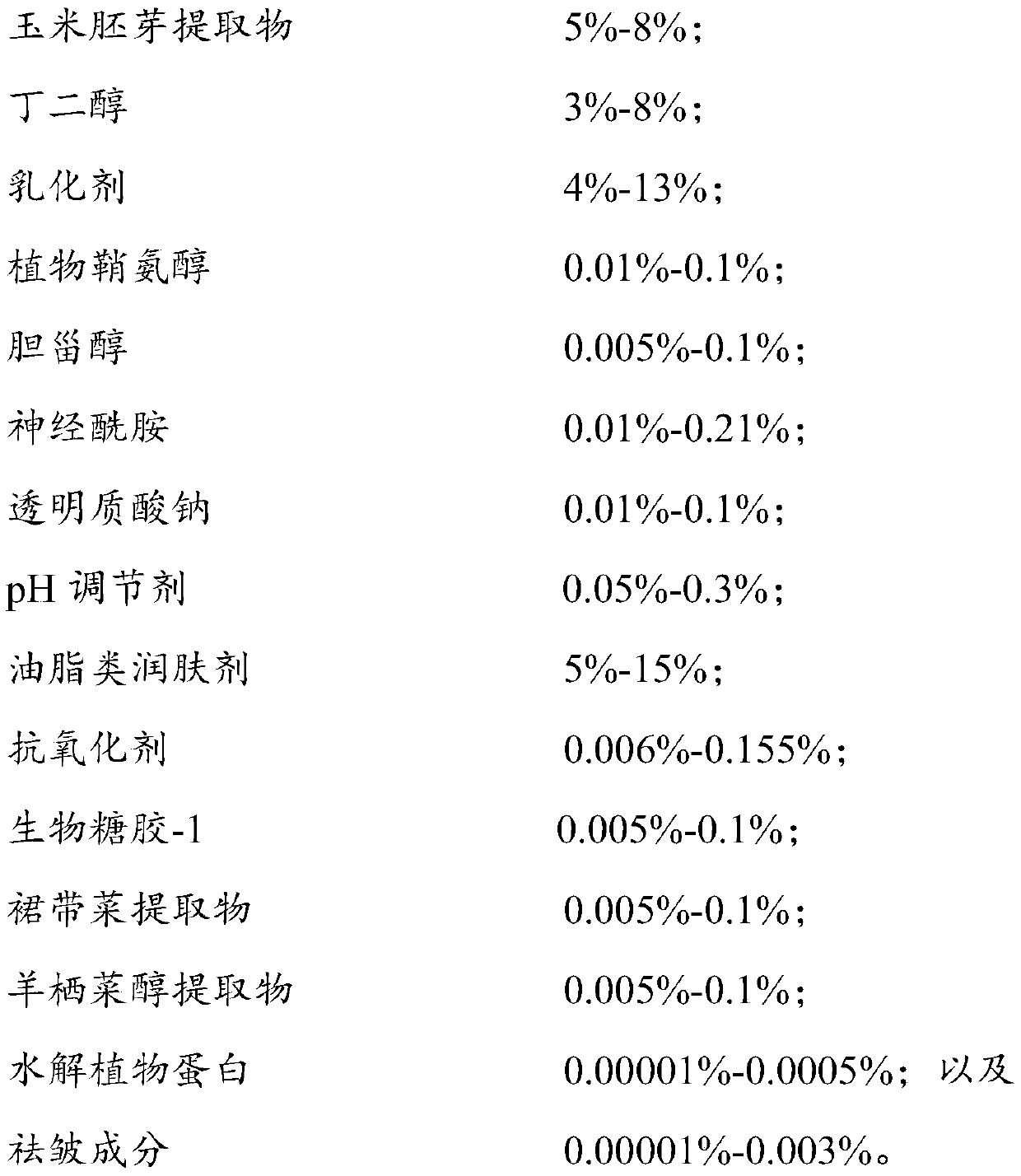

Method used

Image

Examples

preparation example Construction

[0061] The embodiment of the present application also provides a preparation method of the above-mentioned moisturizing and repairing face cream, which includes the following steps:

[0062] Butanediol, phytosphingosine, cholesterol, ceramide, at least part of glycerin and part of water form the first aqueous phase.

[0063] The second aqueous phase formed by adding sodium hyaluronate and part of water into the first aqueous phase is dissolved to obtain a mixed phase.

[0064] In the mixed phase, add at least part of the pH regulator earlier, optionally, add sodium hydroxide earlier, and then add the dispersed phase oil phase formed by the emulsifier and part of the oily emollient (the emulsifier and the oily emollient are heated After dissolving, it is in a liquid state), after dissolving, add the remaining at least part of the oil phase formed by the oily emollient under stirring conditions, that is, pour the oil phase into the water phase under stirring conditions, and add ...

Embodiment 1

[0115] The present embodiment provides a moisturizing and repairing face cream, which is prepared according to the following steps:

[0116] 1. Prepare raw materials:

[0117] 1. Solvent: water 60kg;

[0118] 2. Moisturizer: glycerin 3kg; corn germ extract 2kg;

[0119] 3. Moisturizing agent: butanediol 5kg;

[0120] 4. Skin conditioner: water 4kg; sodium lauroyl lactylate 0.5kg; phytosphingosine 0.1kg; ceramide 30.1kg; phenoxyethanol 0.1kg; ceramide 6II 0.1kg; cholesterol 0.1kg; xanthan gum 0.05 kg; Ethylhexylglycerin 0.03kg; Carbomer 0.3kg; Ceramide 10.00001kg;

[0121] 5. Preservative: phenoxyethanol 0.1kg;

[0122] 6. Preservatives: Methylparaben 0.2kg; Disodium EDTA 0.02kg; Ethylhexylglycerin 0.1kg;

[0123] 7. Thickener: Carbomer 0.3kg;

[0124] 8. Film-forming agent: sodium polyacrylate 0.1kg; water 1kg;

[0125] 9. Skin conditioning agent: sodium hyaluronate 0.05kg;

[0126] 10. Grease emollient: cyclopentasiloxane 3kg;

[0127] 11. Emulsifier: Sorbitan Tristear...

Embodiment 2

[0150] This example provides a moisturizing and repairing face cream, the preparation steps of which are roughly the same as those of Example 1, except that the raw materials used in this example are as follows:

[0151] 1. Solvent: water 62kg;

[0152] 2. Moisturizer: glycerin 2kg; corn germ extract 2kg

[0153] 3. Moisturizing agent: butanediol 8kg;

[0154] 4. Skin conditioner: water 4kg; sodium lauroyl lactylate 0.3kg; phytosphingosine 0.05kg; ceramide 30.05kg; phenoxyethanol 0.05kg; ceramide 6II 0.05kg; cholesterol 0.05kg; xanthan gum 0.05 kg; Ethylhexylglycerin 0.1kg; Carbomer 0.3kg; Ceramide 10.00001kg;

[0155] 5. Preservative: phenoxyethanol 0.01kg;

[0156] 6. Preservatives: Methylparaben 0.1kg; Disodium EDTA 0.1kg; Ethylhexylglycerin 0.2kg;

[0157] 7. Thickener: Carbomer 0.4kg;

[0158] 8. Film-forming agent: sodium polyacrylate 0.1kg; water 1kg;

[0159] 9. Skin conditioning agent: sodium hyaluronate 0.1kg;

[0160] 10. Grease emollient: cyclopentasiloxane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com