Acid-basebifunctional solid catalyst as well as preparation method and application thereof

A solid catalyst, acid-base dual-function technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of poor performance and stability of ionic liquids, cumbersome preparation process, and inability to use in large quantities. Easy to separate, recyclable, less dosage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

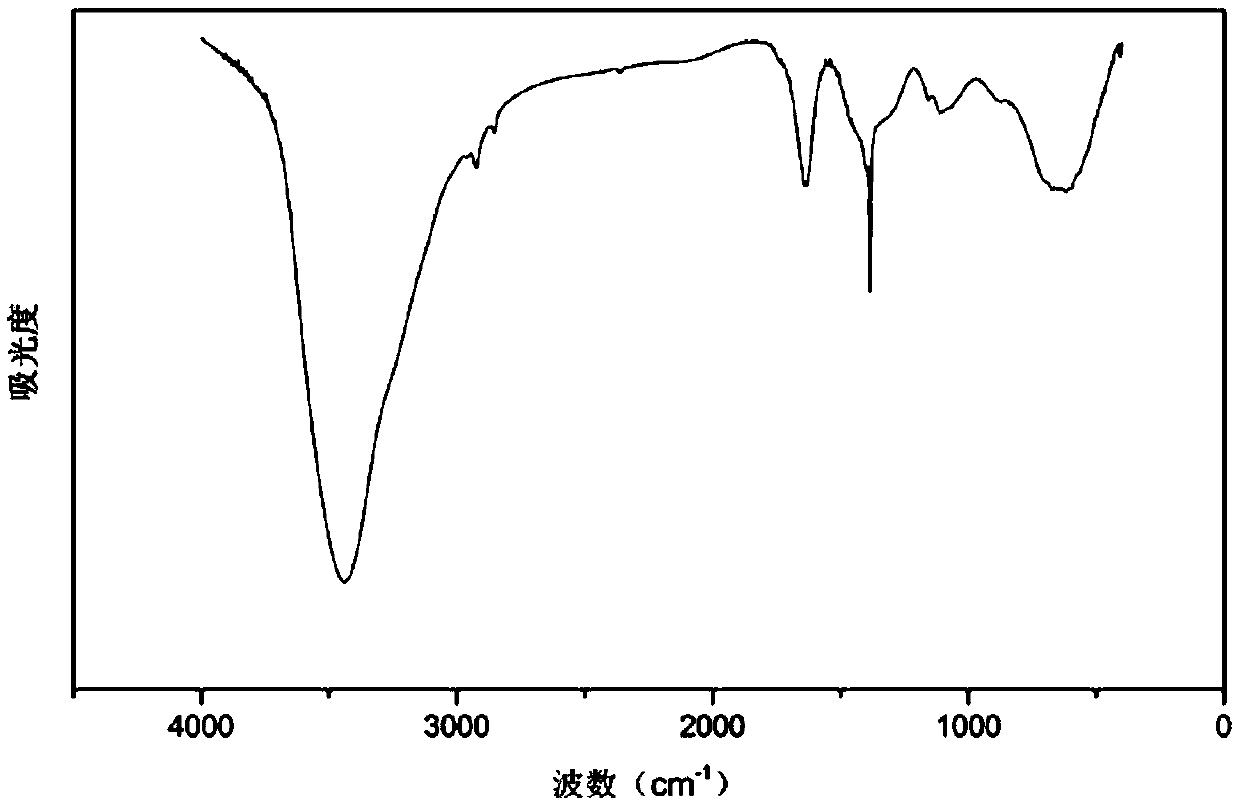

Image

Examples

Embodiment 1

[0047] A preparation method for an acid-base bifunctional solid catalyst, comprising the steps of:

[0048] S1. Add 1.0g P123 and 20g absolute ethanol to a round bottom flask, stir at 35°C for 3h, add 1.0g aluminum isopropoxide, continue stirring for 4h, add HCl to adjust the pH to 1, continue stirring for 1h, then add 4.0g benzene Boric acid, continue to stir for 1h;

[0049] S2. The above-mentioned mixed solution was sonicated for 1 hour, and then placed at 80° C. for two days for volatile self-assembly to obtain the residue after volatile self-assembly;

[0050] S3. Calcining the above residue to prepare an acid-base bifunctional solid catalyst, wherein the calcination temperature is 400° C. and the calcination time is 6 hours to obtain a solid catalyst.

[0051] A preparation method of 5-HMF, comprising the following steps: weighing 0.02g of catalyst, adding 0.05g of glucose into 11g of DMSO, reacting at 140°C for 240min, and quenching after the reaction.

[0052] The mo...

Embodiment 2

[0054] A preparation method for an acid-base bifunctional solid catalyst, comprising the steps of:

[0055] S1. Add 1.0g P123 and 20g absolute ethanol to a round bottom flask, stir at 35°C for 3h, add 4.0g aluminum isopropoxide, continue stirring for 4h, add HCl to adjust the pH to 1, continue stirring for 1h, then add 1.0g benzene Boric acid, continue to stir for 1h;

[0056] S2. The above-mentioned mixed solution was sonicated for 1 hour, and then placed at 80° C. for two days for volatile self-assembly to obtain the residue after volatile self-assembly;

[0057] S3. Calcining the above residue to prepare an acid-base bifunctional solid catalyst, wherein the calcination temperature is 400° C. and the calcination time is 6 hours to obtain a solid catalyst.

[0058] A preparation method of 5-HMF, comprising the following steps: weighing 0.02g of catalyst, adding 0.05g of glucose into 11g of DMSO, reacting at 140°C for 240min, and quenching after the reaction.

[0059] The mo...

Embodiment 3

[0061] A preparation method for an acid-base bifunctional solid catalyst, comprising the steps of:

[0062] S1. Add 1.0g P123 and 20g absolute ethanol to a round bottom flask, stir at 35°C for 3h, add 1.0gAl-SBA-15, continue stirring for 4h, add HCl to adjust the pH to 1, continue stirring for 1h, then add 1.0g phosphorus Tungstic acid, continue to stir for 1h;

[0063] S2. The above-mentioned mixed solution was sonicated for 1 hour, and then placed at 80° C. for two days for volatile self-assembly to obtain the residue after volatile self-assembly;

[0064] S3. Calcining the above residue to prepare an acid-base bifunctional solid catalyst, wherein the calcination temperature is 400° C. and the calcination time is 6 hours to obtain a solid catalyst.

[0065] A preparation method of 5-HMF, comprising the following steps: weighing 0.02g of catalyst, adding 0.05g of glucose into 11g of DMSO, reacting at 140°C for 240min, and quenching after the reaction.

[0066] The molar yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com