A kind of ppo nanocomposite material and preparation method thereof

A nano-composite material and nano-material technology, applied in the field of nano-composite materials, can solve the problems of polyamide not entering the interlayer in time and affecting product performance, so as to avoid poor performance of nano-composite materials, facilitate production and processing, and have superior performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] 1. Preparation of paste

[0111] The nano material is montmorillonite, the liquid medium is water, the auxiliary agent is pectin, the thermoplastic polymer is PPO, and the antiaging agent is antioxidant 264.

[0112] Nanomaterial 1 part by weight

[0113] 10 parts by weight of liquid medium

[0114] Auxiliary 0.01 parts by weight

[0115] The nanomaterials and additives are sequentially added into the liquid medium and dispersed, wherein the adding speeds of the nanomaterials and additives are respectively 0.01 g / min to prepare a paste with a consistency of 2 mm.

[0116] 2. Preparation of mixture

[0117] Thermoplastic polymer 5 parts by weight

[0118] Anti-aging agent 0.005 parts by weight

[0119] The paste, anti-aging agent and thermoplastic polymer are mixed to obtain a compound.

[0120] 3. Preparation of nanocomposites

[0121] Melt and blend the mixed materials, wherein, the mixed materials are added to the solid conveying area of the twin-screw extrud...

Embodiment 2

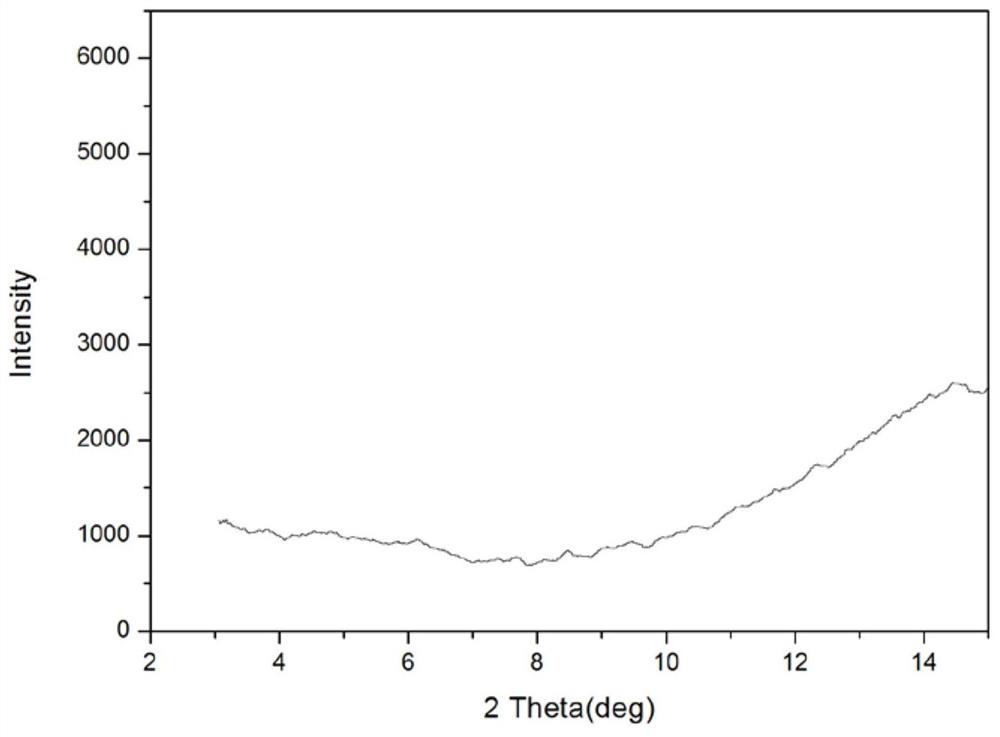

[0123] The nanometer material is kaolin, the liquid medium is isopentane, the auxiliary agent is chitosan, the thermoplastic polymer is PPO, and the antiaging agent is antioxidant TNP.

[0124] 1. Preparation of paste

[0125] Nanomaterial 1 part by weight

[0126] Liquid medium 5 parts by weight

[0127] Auxiliary 1.5 parts by weight

[0128] The nanomaterials and additives are sequentially added into the liquid medium and dispersed, wherein the adding speeds of the nanomaterials and additives are respectively 1 g / min to prepare a paste with a consistency of 10 mm.

[0129] 2. Preparation of mixture

[0130] 50 parts by weight of thermoplastic polymer

[0131] Anti-aging agent 0.1 parts by weight

[0132] The paste, anti-aging agent and thermoplastic polymer are mixed to obtain a compound.

[0133] 3. Preparation of nanocomposites

[0134] Melt and blend the mixed materials, wherein, the mixed materials are added to the solid conveying area of the twin-screw extruder...

Embodiment 3

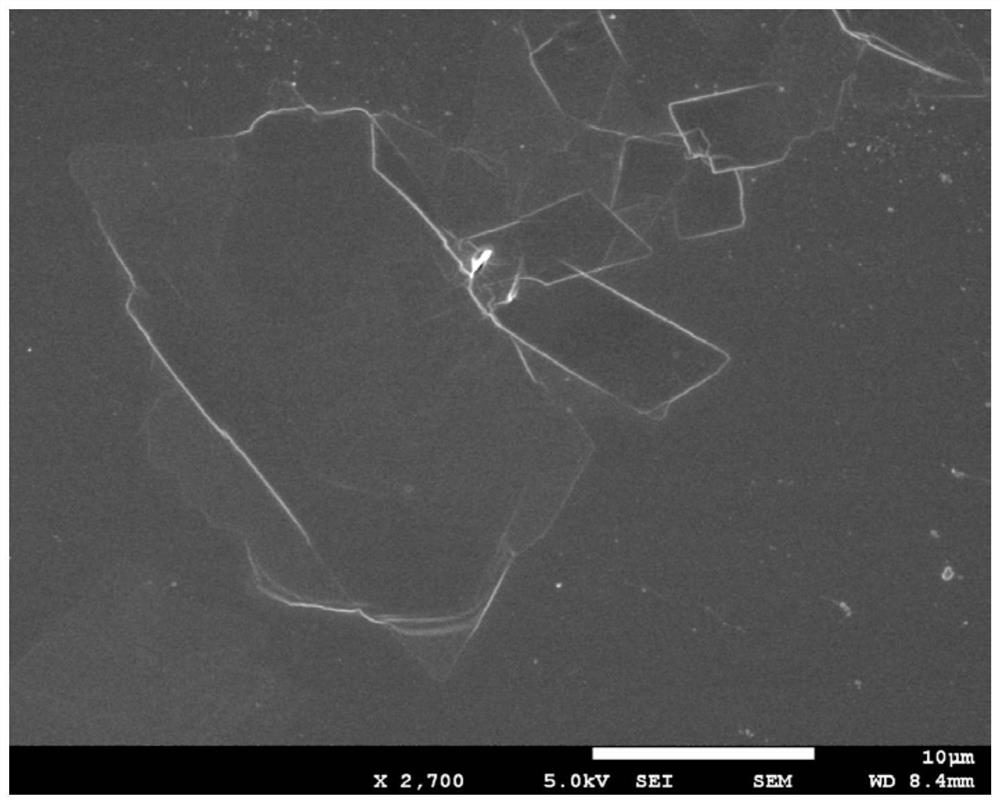

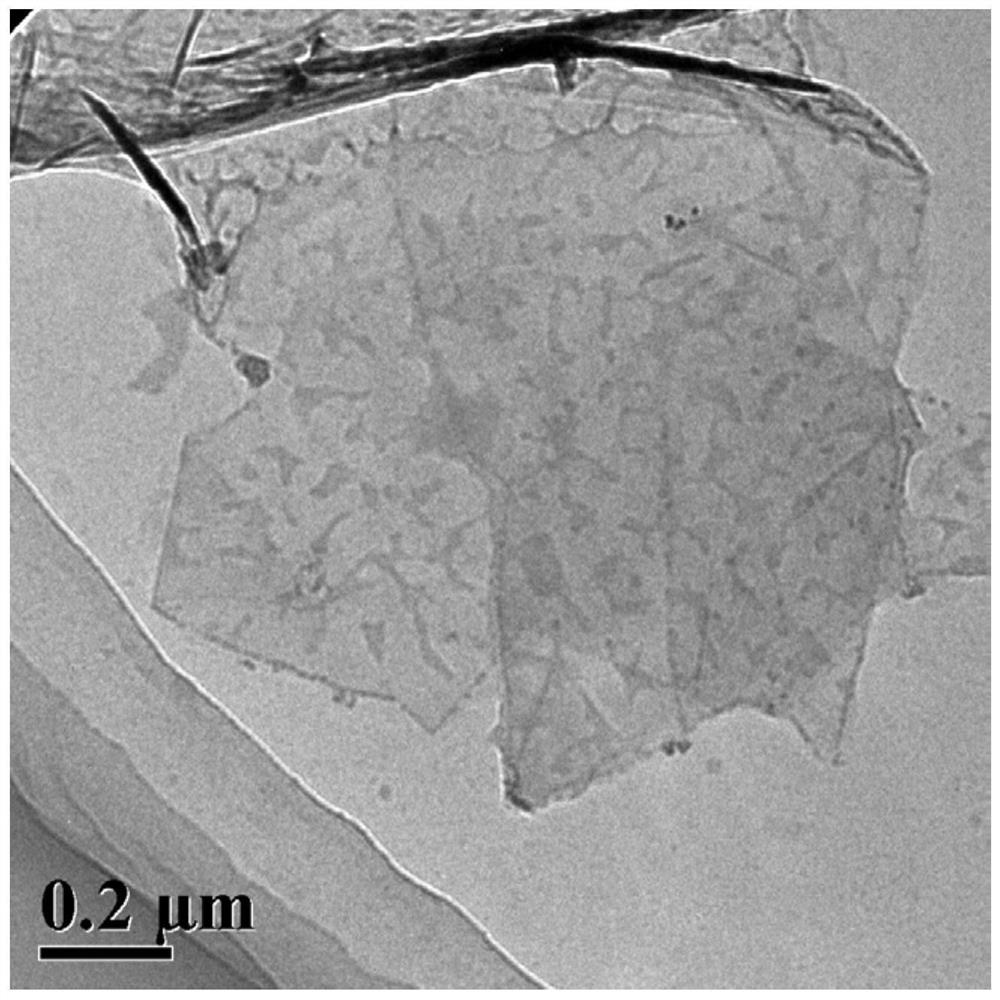

[0136] The nanomaterial is graphene, the liquid medium is dimethylamine, the auxiliary agent is xanthan gum, the thermoplastic polymer is PPO, and the antiaging agent is antioxidant 3114.

[0137] 1. Preparation of paste

[0138] Nanomaterial 1 part by weight

[0139] 30 parts by weight of liquid medium

[0140] Auxiliary 5 parts by weight

[0141] The nanomaterials and additives are sequentially added into the liquid medium and dispersed, wherein the adding speeds of the nanomaterials and additives are respectively 10 g / min to prepare a paste with a consistency of 30 mm.

[0142] 2. Preparation of mixture

[0143] 100 parts by weight of thermoplastic polymer

[0144] 1 part by weight of anti-aging agent

[0145] The paste, anti-aging agent and thermoplastic polymer are mixed to obtain a compound.

[0146] 3. Preparation of nanocomposites

[0147] Melt and blend the mixed materials, wherein, the mixed materials are added to the solid delivery area of the twin-screw ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com