A kind of compound and preparation method thereof

A technology of mixing materials and nanomaterials, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve the problems of polyamide failing to enter the interlayer in time and product performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

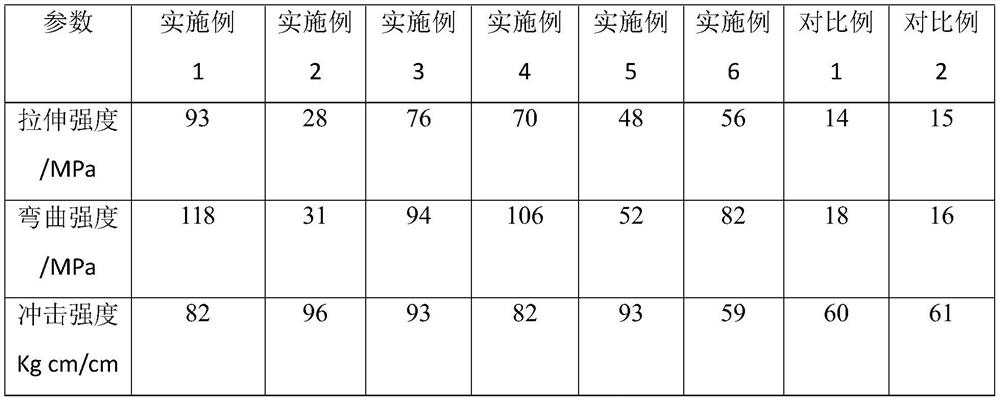

Examples

Embodiment 1

[0084] 1. Preparation of sticky material

[0085] The nano material is nano silicon oxide, the liquid medium is water, the auxiliary agent is pectin, the thermoplastic polymer is PA6, and the antiaging agent is antioxidant 264.

[0086] Nanomaterial 1 part by weight

[0087] 10 parts by weight of liquid medium

[0088] Auxiliary 0.01 parts by weight

[0089] The nanomaterials and additives are sequentially added into the liquid medium and dispersed, wherein the adding speeds of the nanomaterials and additives are respectively 0.01 g / min to obtain a sticky coating with a consistency of 5 mm.

[0090] 2. Preparation of mixture

[0091] Thermoplastic polymer 5 parts by weight

[0092] Anti-aging agent 0.005 parts by weight

[0093] The adhesive, anti-aging agent and thermoplastic polymer are mixed to obtain a compound.

[0094] 3. Preparation of nanocomposites

[0095] Melt and blend the mixed materials, wherein, the mixed materials are added to the solid conveying area of...

Embodiment 2

[0097] The nano material is nano carbon, the liquid medium is isopentane, the auxiliary agent is chitosan, the thermoplastic polymer is PP, and the antiaging agent is antioxidant TNP.

[0098] 1. Preparation of sticky material

[0099] Nanomaterial 1 part by weight

[0100] Liquid medium 5 parts by weight

[0101] Auxiliary 1.5 parts by weight

[0102] The nanomaterials and additives are sequentially added into the liquid medium and dispersed, wherein the adding speeds of the nanomaterials and additives are respectively 1 g / min to prepare a coating with a consistency of 20 mm.

[0103] 2. Preparation of mixture

[0104] 50 parts by weight of thermoplastic polymer

[0105] Anti-aging agent 0.1 parts by weight

[0106] The adhesive, anti-aging agent and thermoplastic polymer are mixed to obtain a compound.

[0107] 3. Preparation of nanocomposites

[0108] Melt and blend the mixed materials, wherein, the mixed materials are added to the solid conveying area of the twin-...

Embodiment 3

[0110] The nano material is nano silicon carbide, the liquid medium is dimethylamine, the auxiliary agent is xanthan gum, the thermoplastic polymer is PC, and the antiaging agent is antioxidant 3114.

[0111] 1. Preparation of sticky material

[0112] Nanomaterial 1 part by weight

[0113] 30 parts by weight of liquid medium

[0114] Auxiliary 5 parts by weight

[0115] The nanomaterials and additives are sequentially added into the liquid medium and dispersed, wherein the adding speeds of the nanomaterials and additives are respectively 10 g / min to prepare a coating with a consistency of 50 mm.

[0116] 2. Preparation of mixture

[0117] 100 parts by weight of thermoplastic polymer

[0118] 1 part by weight of anti-aging agent

[0119] The adhesive, anti-aging agent and thermoplastic polymer are mixed to obtain a compound.

[0120] 3. Preparation of nanocomposites

[0121] Melt and blend the mixed materials, wherein, the mixed materials are added to the solid delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com