Preparation method of halogen-free low-smoke intrinsic flame-retardant nylon 66 composite material

An intrinsic flame retardant, composite material technology, applied in yarn, fiber processing, textiles and papermaking, etc., can solve the problems of increasing the flame retardant mechanical properties of nylon 66, poor compatibility, large amount of addition, etc., to improve compatibility. The effect of improving flame retardancy and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

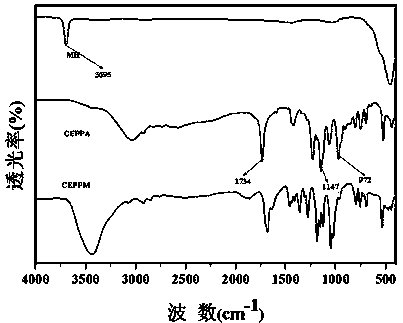

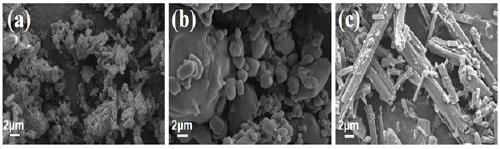

[0031] (1) Preparation of modified flame retardant: Dissolve 2.9 g of magnesium hydroxide in a round-bottomed flask filled with 100 mL of distilled water, ultrasonicate for 30 min; take 10.7 g of 2-carboxyethylphenylphosphinic acid into the flask , magnetic stirring at 100 °C for 5 h, rotary evaporation to remove the solvent, and drying at 80 °C for 24 h to obtain 2-carboxyethylphenylphosphinic acid modified magnesium hydroxide flame retardant;

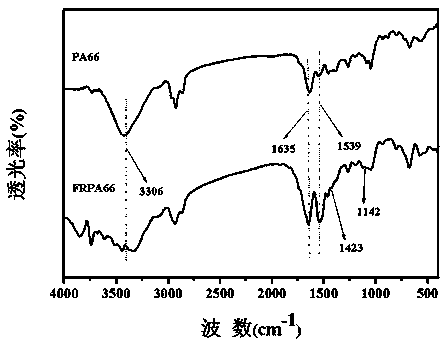

[0032](2) Synthesis of halogen-free, low-smoke intrinsic flame-retardant nylon 66: Take 500 g of nylon 66 salt, prepare a 60% salt solution with 333 mL of distilled water, add 1.625 g of adipic acid to adjust the pH of the solution to about 7.6; take 8 g of the modified magnesium hydroxide flame retardant synthesized above were dispersed in distilled water, and 4 g of 1,6-hexanediamine was added to adjust the pH of the solution to about 7.6; Fill the reactor with nitrogen and discharge the air in the system. After three gas replacemen...

Embodiment 2

[0035] (1) Preparation of modified flame retardant: Dissolve 3.9 g of aluminum hydroxide in a round-bottomed flask filled with 100 mL of distilled water, sonicate for 30 min, add 8.66 g of p-aminobenzenesulfonic acid into the flask, and magnetically Stir for 5 h to remove the solvent by rotary evaporation, and dry at 80°C for 24 h to obtain a p-aminobenzenesulfonic acid modified aluminum hydroxide flame retardant;

[0036] (2) Synthesis of halogen-free, low-smoke intrinsic flame-retardant nylon 66: the added flame retardant is p-aminobenzenesulfonic acid modified aluminum hydroxide flame retardant, and the others are the same as in Example 1;

[0037] (3) Flame retardant performance of intrinsic flame retardant nylon 66 composite material: LOI=24.9%; THR=98.3 MJ / m 2 , PHRR=860.5kW / m 2 , TSP=8.3 m 2 .

Embodiment 3

[0039] (1) Preparation of modified flame retardant: Organic functionalization of magnesium hydroxide: Dissolve 2.9 g of magnesium hydroxide in a round-bottomed flask filled with 100 mL of distilled water, sonicate for 30 min, and dissolve 8.66 g of p-aminobenzenesulfonic acid Add to the flask, stir magnetically at 90°C for 5h, remove the solvent by rotary evaporation, and dry at 80°C for 24h to obtain a magnesium hydroxide flame retardant modified with p-aminobenzenesulfonic acid.

[0040] (2) Synthesis of halogen-free low-smoke intrinsic flame-retardant nylon 66: the added flame retardant is magnesium hydroxide flame retardant modified by p-aminobenzenesulfonic acid, and the others are the same as in Example 1;

[0041] (3) Flame retardant properties of intrinsically flame retardant nylon 66 composites: LOI=25.3%; THR=97.9 MJ / m 2 , PHRR=843.5kW / m 2 , TSP=8.0 m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com