Lithium ion battery anode slurry as well as preparation method thereof, pole piece, and lithium ion battery

A lithium ion battery and positive electrode slurry technology, which is applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of low equipment utilization, long time, and many dispersion steps, so as to reduce mixing time and slurry quality Improve and reduce the effect of reunion behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

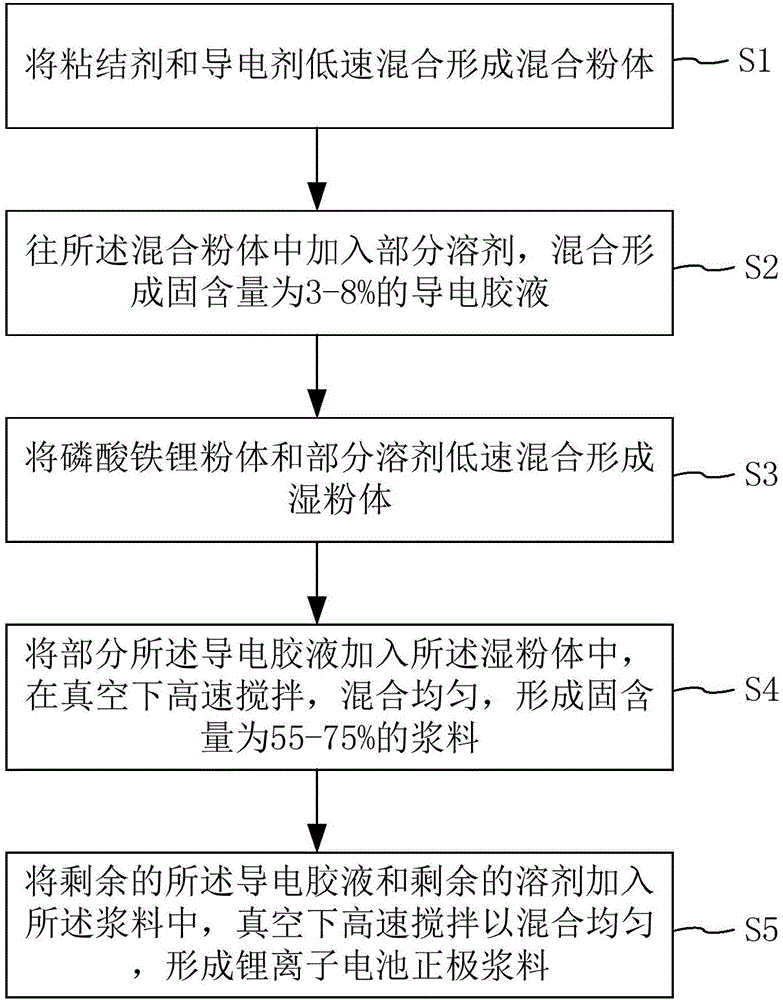

[0024] like figure 1 Shown, the preparation method of the positive electrode slurry of lithium ion battery of an embodiment of the present invention, comprises the following steps:

[0025] S1. Mix the binder and the conductive agent at a low speed to form a mixed powder.

[0026] Among them, the mixing of the binder and the conductive agent is preferably carried out in a double planetary mixer. The rotation speed of the low speed is 10-20rpm / min. The mixing time can be 10-30 minutes.

[0027] The binder is one or more of polyvinylidene fluoride, polytetrafluoroethylene, acrylate, and polyurethane; the conductive agent is one or more of conductive carbon black, conductive graphite, and carbon fiber.

[0028] In order to mix the binder powder and conductive agent powder evenly in the shortest time, when adding, first add 50% (amount) of binder, then add 100% (amount) of conductive agent, and first mix Then add the remaining 50% of the binder. The binder and the conductive ...

Embodiment 1

[0048] Set each of the following to represent 1000g;

[0049] Take 3 parts of PVDF (polyvinylidene fluoride), 2 parts of Super-P (conductive carbon black), and 1 part of KS-6 (conductive graphite) in a mixer at a speed of 10 rpm for 20 minutes to form a mixed powder. After adding 69 parts of N-methylpyrrolidone, stirring at 20 rpm and dispersing at 1000 rpm for 90 minutes, increase the vacuum to -0.095Mpa and continue mixing for 120 minutes to form a conductive glue. Take 94 parts of lithium iron phosphate powder and add it to another mixer, and add 3 parts of N-methylpyrrolidone at 10 rpm and mix uniformly for 20 minutes to form a wet powder. Add 42 parts of conductive glue, mix at a stirring speed of 25rpm, a dispersion speed of 1000rpm, and a vacuum of -0.095Mpa for 120 minutes. Continue to add the remaining 33 parts of conductive glue and 31 parts of N-methylpyrrolidone. The stirring speed is 25 rpm, the dispersion speed is 2500 rpm, the vacuum degree is -0.095Mpa, and th...

Embodiment 2

[0051] Set each of the following to represent 1000g;

[0052]Take 3 parts of PTFE (polytetrafluoroethylene) and 3 parts of conductive carbon black and mix them uniformly for 20 minutes at a speed of 10 rpm in a mixer to form a mixed powder. After adding 69 parts of N-methylpyrrolidone, stirring at 20 rpm and dispersing at 500 rpm for 90 minutes, increase the vacuum to -0.095Mpa and continue mixing for 120 minutes to form a conductive glue. Take 94 parts of lithium iron phosphate powder and add it to another mixer, and add 5 parts of N-methylpyrrolidone at 10 rpm and mix uniformly for 20 minutes to form a wet powder. Add 42 parts of conductive glue, mix at a stirring speed of 25rpm, a dispersion speed of 1000rpm, and a vacuum of -0.095Mpa for 120 minutes. Continue to add the remaining 33 parts of conductive glue and 31 parts of N-methylpyrrolidone. The stirring speed is 25 rpm, the dispersion speed is 2500 rpm, the vacuum degree is -0.095Mpa, and the mixing time is 60 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com