Graphene-carbon nanotube composite fiber felt and preparation method thereof

A carbon nanotube composite and carbon nanotube fiber technology, applied in the field of fiber felt, can solve the problems of incompetence, poor interface bonding strength, etc., and achieve strong tensile strength and bending strength, strong interface bonding force, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The first aspect of the present invention provides a kind of preparation method of graphene-carbon nanotube composite fiber felt, comprises the steps:

[0022] (1) treating the graphene-carbon nanotube composite fiber with a silane coupling agent to obtain a modified composite fiber;

[0023] (2) arranging the modified fiber into a felt shape, and impregnating it with a sizing agent to obtain a sizing-treated composite fiber;

[0024] (3) Hot pressing the sizing-treated composite fibers to obtain a graphene-carbon nanotube composite fiber mat.

[0025] In a preferred embodiment, the preparation method of the graphene-carbon nanotube composite fiber mat comprises the steps of:

[0026] (1) Treating the graphene-carbon nanotube composite fiber with an aqueous solution of a silane coupling agent for 10 to 20 seconds, and then drying at 100 to 120° C. for 10 to 30 seconds to obtain a modified composite fiber;

[0027] (2) arranging the modified fiber into a felt shape, an...

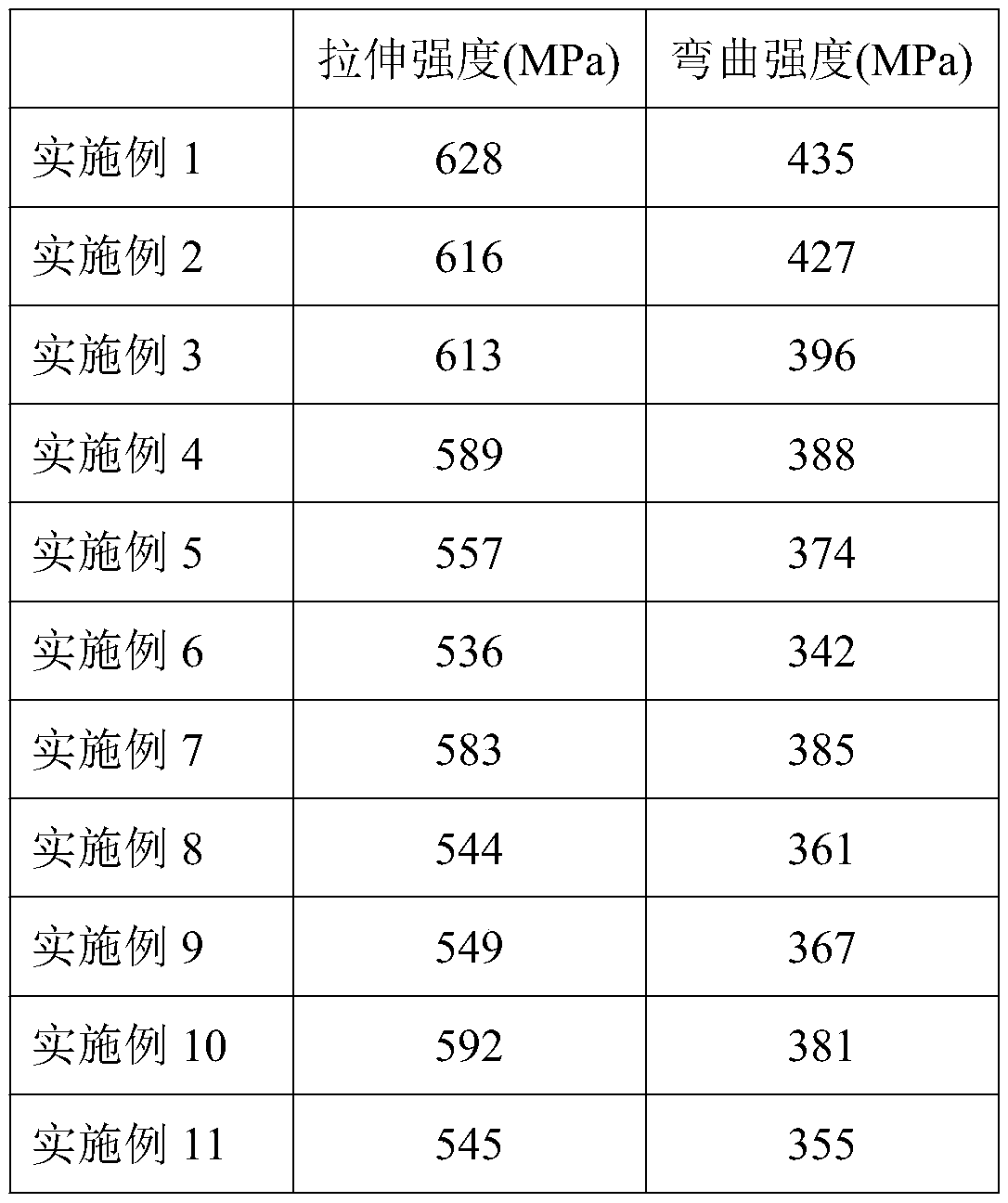

Embodiment 1

[0094] Embodiment 1 of the present invention provides a kind of graphene-carbon nanotube composite fiber felt, and its preparation method is as follows:

[0095] (1) Treat the graphene-carbon nanotube composite fiber with a concentration of 0.3wt% silane coupling agent aqueous solution for 15s, then dry it at 110°C for 20s to obtain the modified composite fiber;

[0096] (2) arrange the modified fiber into a felt, and impregnate it with a sizing agent for 20s to obtain a sizing-treated composite fiber;

[0097] (3) Carry out hot pressing to the composite fiber of sizing treatment, the temperature of hot pressing is 130 DEG C, the pressure is 0.25MPa, then dry at 110 DEG C for 3min, obtains the graphene-carbon nanotube composite fiber mat;

[0098] The length of graphene-carbon nanotube composite fiber is 35mm;

[0099] The silane coupling agent is γ-aminopropyltrimethoxysilane;

[0100] The raw materials for the preparation of the sizing agent include the first component and...

Embodiment 2

[0107] Embodiment 2 of the present invention provides a kind of graphene-carbon nanotube composite fiber felt, and its preparation method is as follows:

[0108] (1) Treating the graphene-carbon nanotube composite fiber with a concentration of 0.5wt% silane coupling agent aqueous solution for 20s, then drying at 120°C for 30s to obtain the modified composite fiber;

[0109] (2) arrange the modified fiber into a felt, and impregnate it with a sizing agent for 30s to obtain a sizing-treated composite fiber;

[0110] (3) Carry out hot pressing to the composite fiber of sizing treatment, the temperature of hot pressing is 140 ℃, the pressure is 0.4MPa, then dry 5min at 120 ℃, obtain graphene-carbon nanotube composite fiber mat;

[0111] The length of graphene-carbon nanotube composite fiber is 50mm;

[0112] The silane coupling agent is γ-aminopropyltrimethoxysilane;

[0113] The raw materials for the preparation of the sizing agent include the first component and the second com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com