Water-free reactive dye printing paste and printing process

A printing color paste and printing process technology, applied in the field of textile dyeing and finishing, can solve the problems of low color fastness level of printed textiles, high COD value of soaping wastewater, low color fixation rate of reactive dyes, etc., to achieve high color fastness, Accelerate the dyeing rate and weaken the effect of charge repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] S1, take a certain amount of dimethylformamide, and add a certain amount of polyurethane into the dimethylformamide under stirring, the weight percentage of polyurethane is 30wt%;

[0047] S2, take 50g of a polyurethane solution with a weight percentage of 30wt%, and add 1g of reactive blue 222 to the polyurethane solution while stirring, then add 50g of tetrachlorethylene to the polyurethane solution, continue stirring for 30min, and prepare a dye C at a concentration of 10 g / L 2 Cl 4 -The printing paste of DMF-PU system (50:50), namely obtains the printing paste of anhydrous reactive dyes;

[0048] S3, using the water-free reactive dye printing paste obtained in step S2 to print the textile to be printed;

[0049] S4, taking out the textile and drying it;

[0050] S5, sequentially soaping and washing the dried textiles.

Embodiment 2-5

[0052] Embodiments 2-5 provide a printing process. Compared with Embodiment 1, the difference is that the weight percentage of polyurethane in step S1 is changed. Except for the above differences, other operations are the same and will not be repeated here; the specific parameters are as follows shown in the table.

[0053]

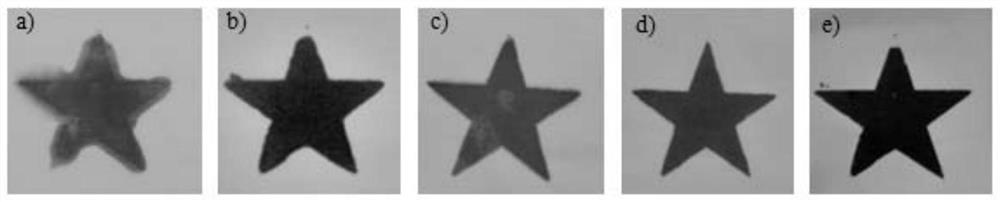

[0054] see figure 1 As shown, from left to right are the samples of Examples 2-5 and Example 1 obtained after drying in step S4. It can be seen from the figure that as the weight percentage of polyurethane (PU) increases, the boundary of the obtained printing pattern (the five-pointed star in the figure) becomes clearer and clearer. It should be noted that when the content of PU is higher than 30wt%, the PU solution cannot be prepared due to too high viscosity.

Embodiment 6

[0056] Embodiment 6 provides a printing process. Compared with Embodiment 1, the difference is that in step S3, Na 2 CO 3 The lye (pure water system) has carried out alkali treatment on the textile to be printed, and the specific operation is as follows:

[0057] S1, take a certain amount of dimethylformamide, and add a certain amount of polyurethane into the dimethylformamide under stirring, the weight percentage of polyurethane is 30wt%;

[0058] S2, take 50g of a polyurethane solution with a weight percentage of 30wt%, and add 1g of reactive blue 222 to the polyurethane solution while stirring, then add 50g of tetrachlorethylene to the polyurethane solution, continue stirring for 30min, and prepare a dye C at a concentration of 10 g / L 2 Cl 4 -The printing paste of DMF-PU system (50:50), namely obtains the printing paste of anhydrous reactive dyes;

[0059] S3`, the Na 2 CO 3 Mix with water, stir evenly to prepare lye; wherein, the bath ratio of lye is 1:20, Na 2 CO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com