Building structure and process of air inlet and conical section of combustion chamber of suspension furnace

A technology of masonry structure and conical section, which is applied in the application field of refractory materials, can solve the problems of conical section refractory brick masonry and other problems, and achieve the effects of long service life, energy saving and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

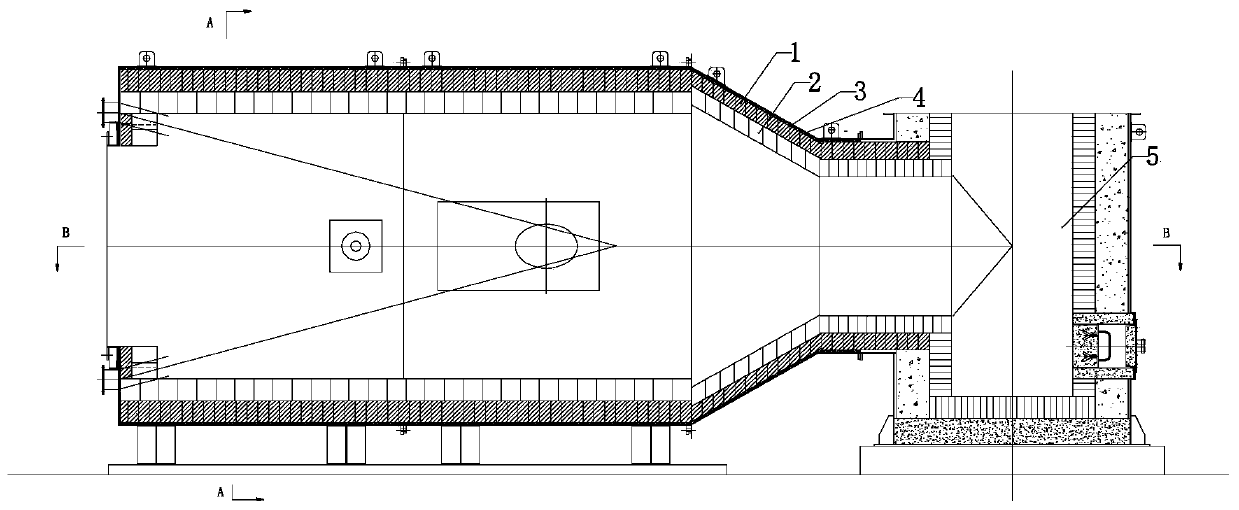

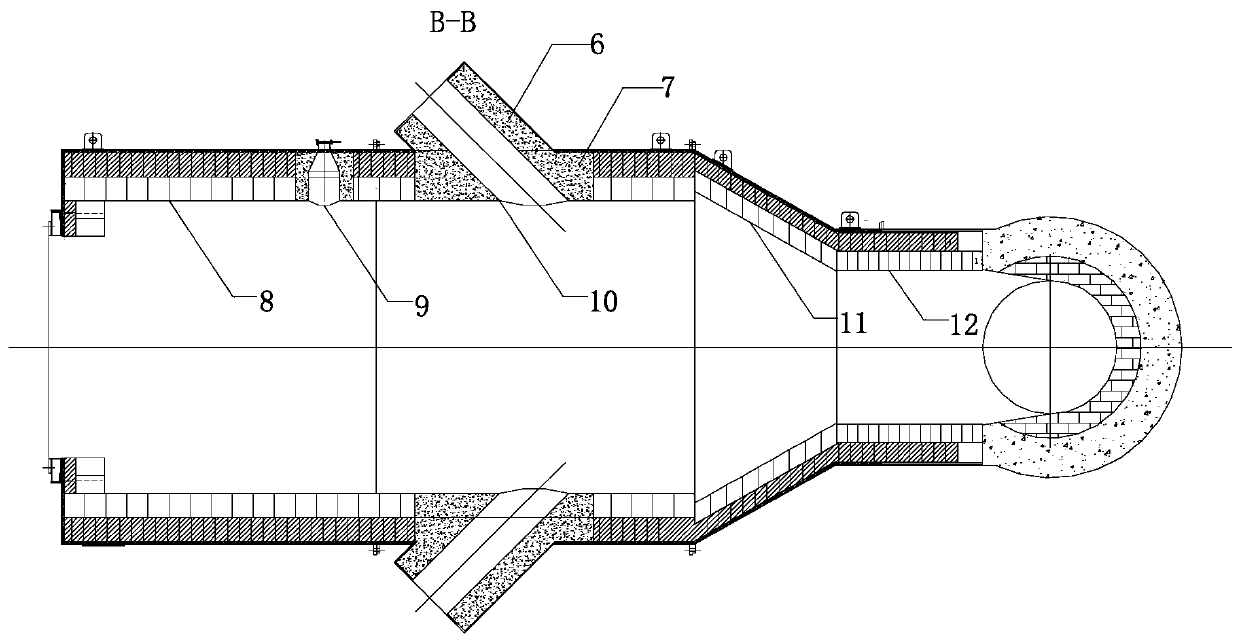

[0033] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

[0034] see Figure 1-Figure 12 , A masonry structure of the air inlet and tapered section of the combustion chamber of a suspension furnace, the combustion chamber of the suspension furnace includes a large straight section 8, a tapered section 11, a small straight section 12, a tuyere 10, and a fire viewing hole 9. The tuyere 10 includes a prefabricated pouring oblique section 6 and a prefabricated block 7. Ventilation holes are reserved in the prefabricated pouring oblique section 6. The prefabricated block 7 is a plurality of rectangular parallelepiped prefabricated blocks, and the prefabricated blocks 7 are reserved therein Ventilation holes, the ventilation holes in the prefabricated block 7 and the ventilation holes in the prefabricated inclined section 6 are coaxial and equal in diameter; the tapered section 11 is used to build the working layer of mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com