High-throughput detecting system for obtaining trace mass and molecular structure information

A molecular structure and detection system technology, applied in the direction of material absorption and weighing, can solve the problems of single free end bending response signal, inability to detect other information of the measured material in real time, inability to analyze the mechanism of structure and mechanical properties, etc., to achieve anti-corrosion Strong interference ability, high sensitivity, good detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

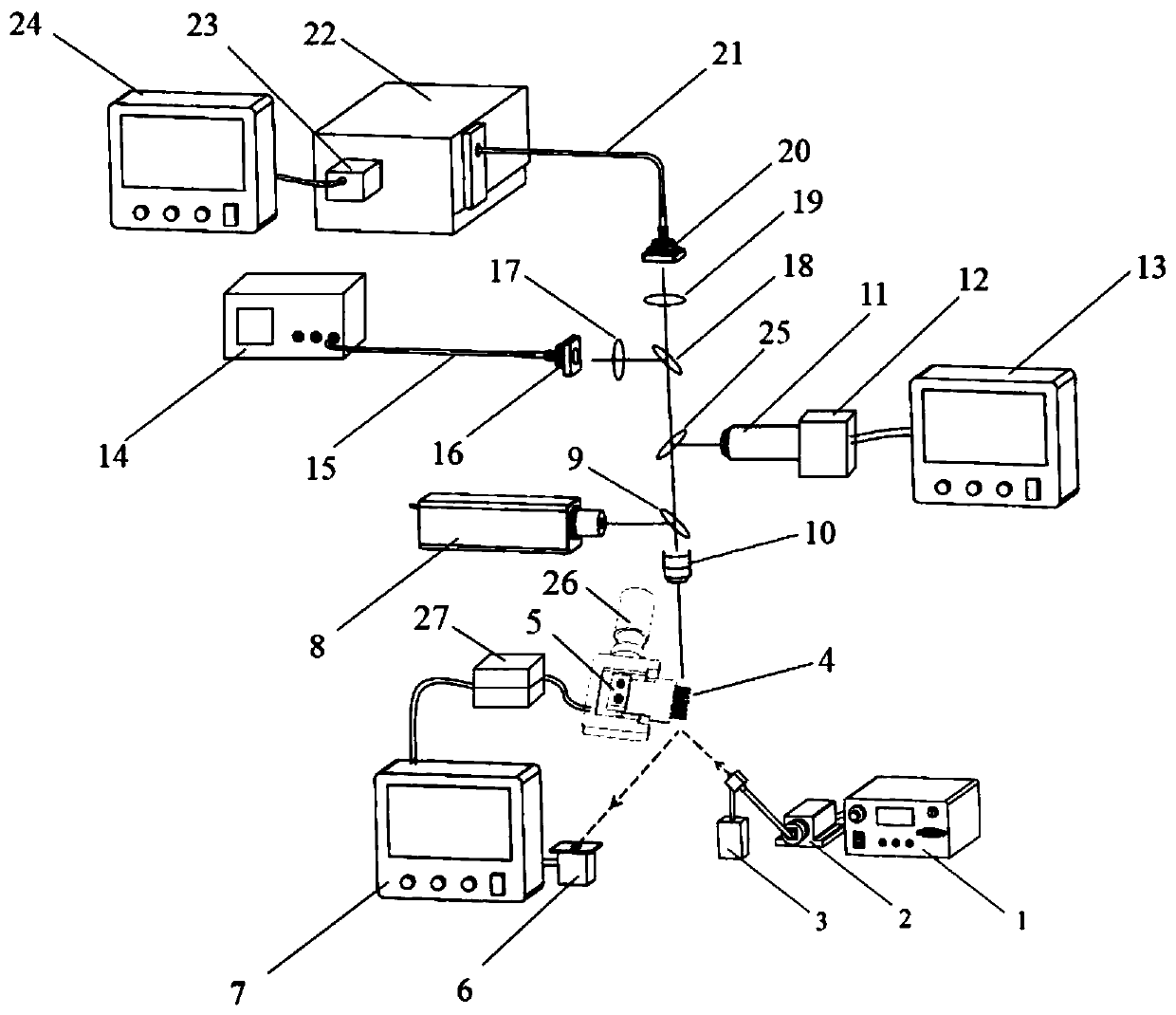

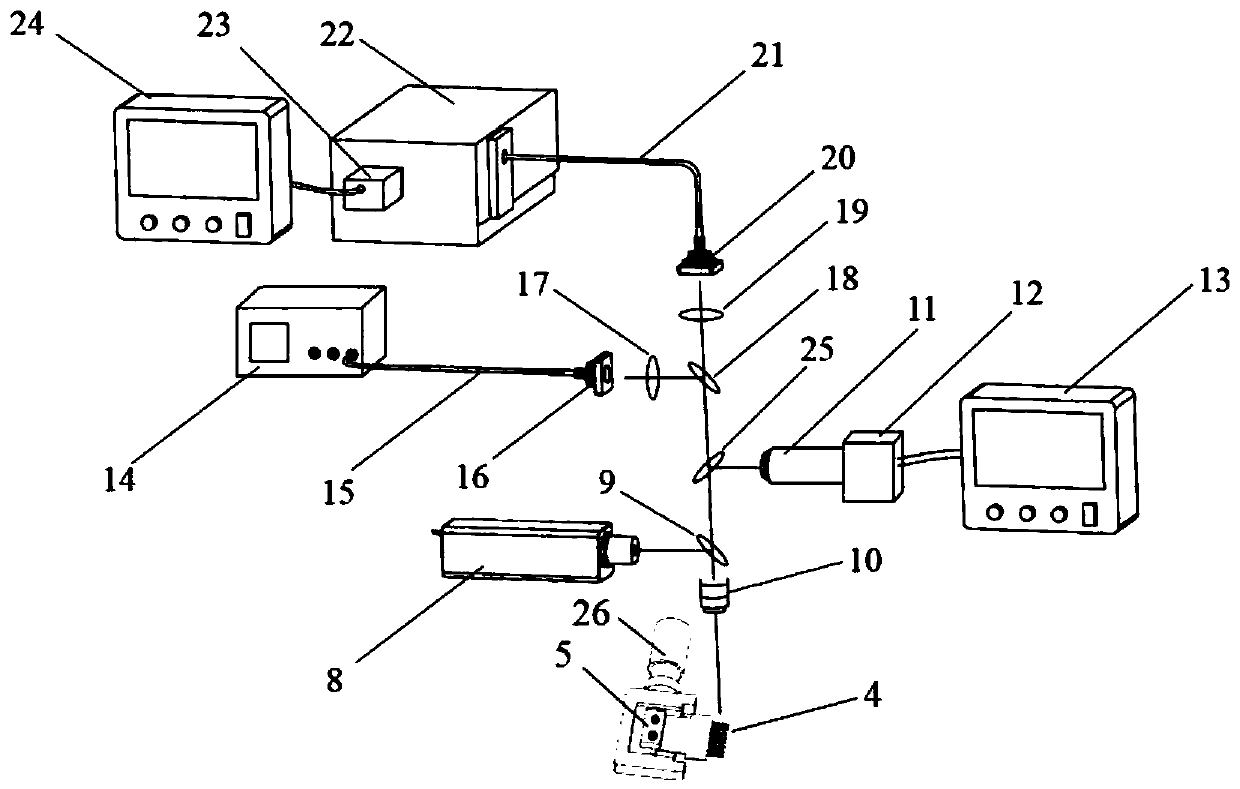

[0033] see figure 1 , the high-throughput detection system used to obtain trace mass and molecular structure information in this embodiment is: composed of a micro-cantilever beam sensing unit and a micro-Raman spectroscopy unit.

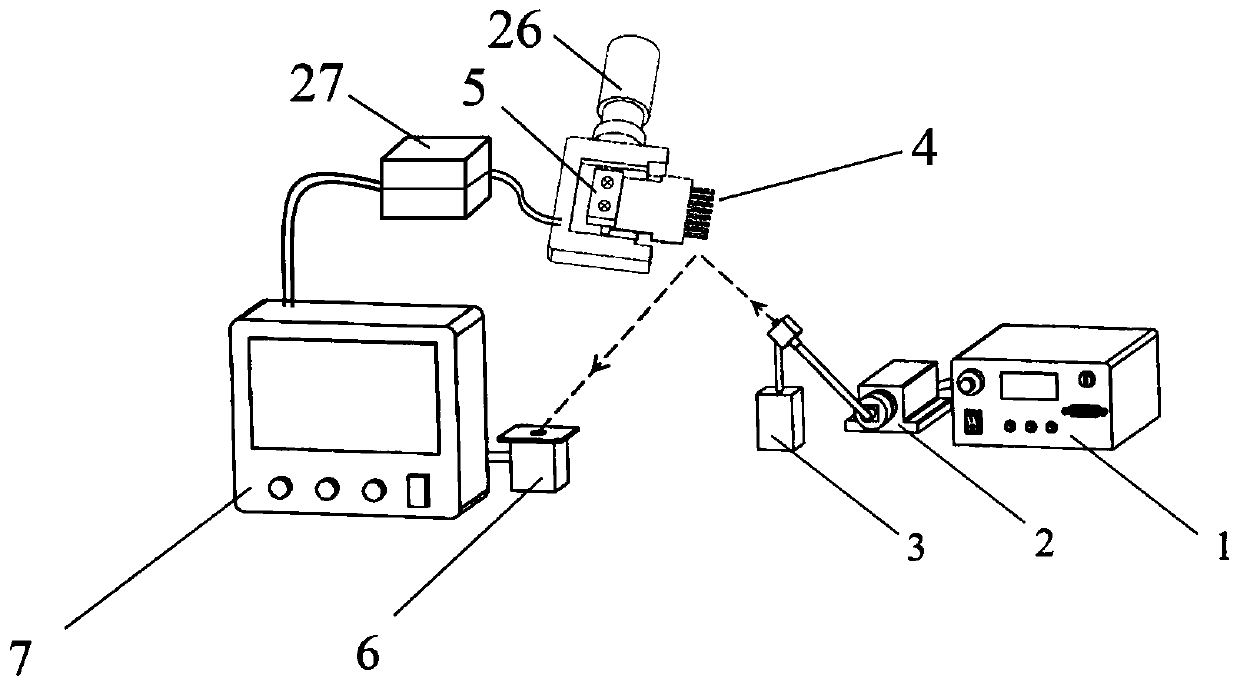

[0034] see figure 1 and figure 2In the present embodiment, in the micro-cantilever sensing unit, a plurality of micro-cantilever beams are arranged side by side to form a micro-cantilever array 4, and the power supply 1 is turned on, and the laser light emitted by the laser device 2 is projected to the micro-cantilever at a set angle through the laser guide device 3. The beam array 4; the micro-cantilever beam array 4 is fixedly arranged on the piezoelectric ceramic driver 5, and the piezoelectric ceramic driver 5 is fixedly arranged on the voice coil motor 26, and the piezoelectric ceramic driver 5 is driven by the voice coil motor 26 to move in translation, thereby driving The micro-cantilever array 4 translates along the width direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com