Large liquid-gas ratio multi-layer cascade dust and mist removal packed tower

A technology of liquid-gas ratio and packed tower, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high pressure loss, increased resistance, poor dehydration effect, etc., and achieve reasonable structural design and low resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

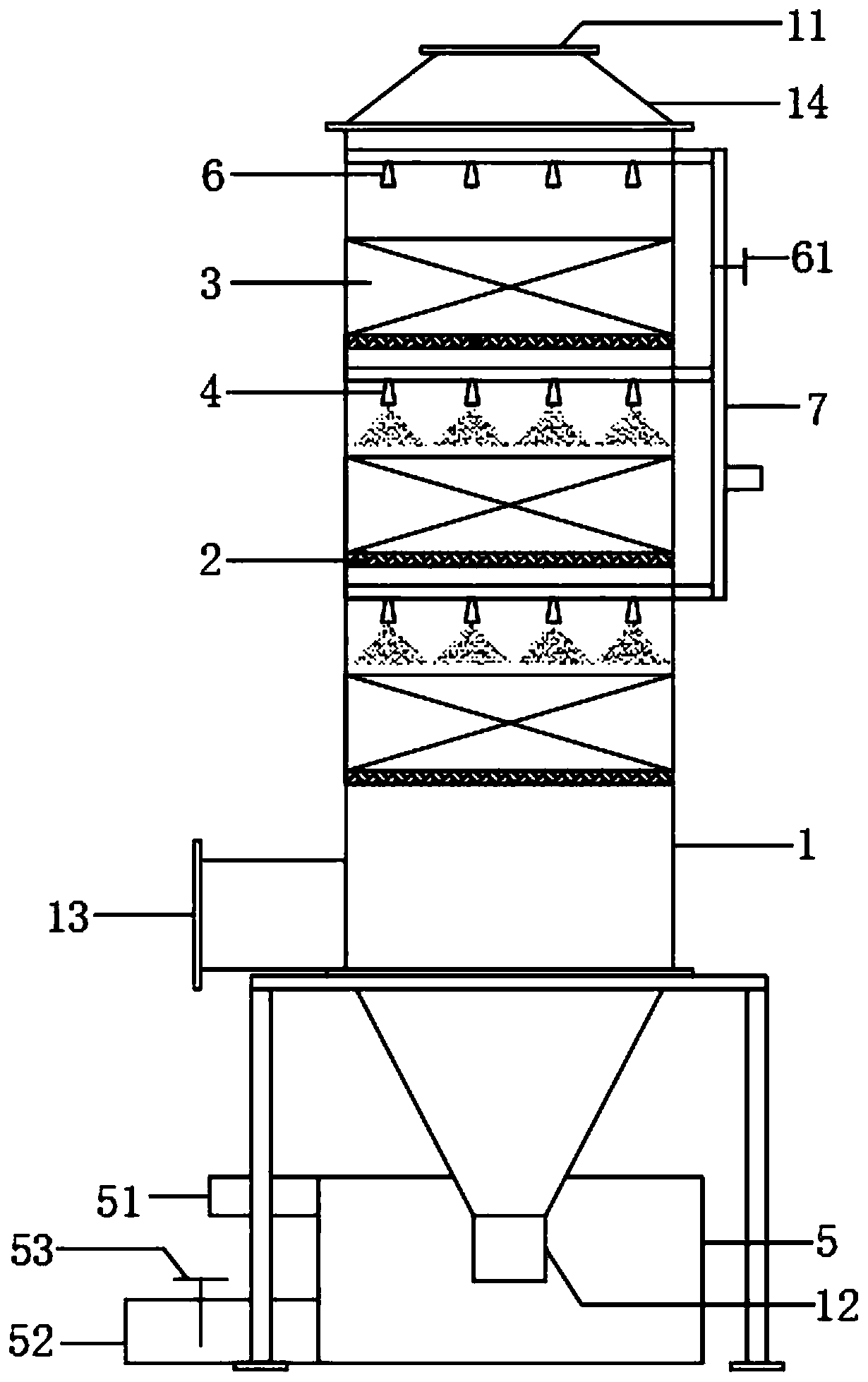

[0038] Example: such as figure 1 As shown, the large liquid-to-gas ratio multi-layer cascade dedusting and demisting packing tower of this embodiment includes a tower body 1, the tower body 1 is a vertically arranged cylindrical structure, and its bottom is fixed on the ground by a bracket. The tower body 1 The top is provided with an exhaust port 11, the bottom is provided with a liquid discharge port 12, and the lower end of the side wall is provided with an air inlet 13; the support frame 2, the above-mentioned support frame 2 is provided with multiple, and is installed on the above-mentioned tower at intervals up and down. body 1, and are all located above the above-mentioned air inlet 13; packing layer 3, the above-mentioned packing layer 3 is provided with multiple layers, and is respectively laid on the upper part of each of the above-mentioned support frame 2, the packing diameter in the multi-layer above-mentioned packing layer 3 Decrease in turn from bottom to top; s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com