Composite nano TiO2 and ZnO water-based epoxy resin floor surface paint and preparation method thereof

A technology of water-based epoxy resin and epoxy floor, applied in the direction of epoxy resin coating, coating, anti-corrosion coating, etc., can solve the problems of weak waterproof ability, poor acid and alkali corrosion resistance, poor hardness, etc., to improve corrosion resistance , Improve the hardness, the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention also provides a composite nano-TiO 2 And the preparation method of ZnO waterborne epoxy floor surface paint, comprises the following steps:

[0040] S1: Preparation of component A: Add nano-TiO to the container respectively2 , nano ZnO, silane coupling agent and deionized water, mix and stir evenly for later use;

[0041] S2: Preparation of component B1: After adding defoamer, dispersant and leveling agent to the container, stir evenly for later use;

[0042] S3: Prepare component B2: add water-based epoxy resin, film-forming aid and reactive diluent to the container, mix and stir evenly, and set aside;

[0043] S4: Mix B1 and B2 components evenly, and then mix them with A component;

[0044] S5: After the three components A, B1, and B2 are mixed, they are ultrasonically treated at 48°C to 52°C for 1h to 1.5h, then taken out and cooled;

[0045] S6: After the above three components A, B1 and B2 are cooled, add component B3 and ...

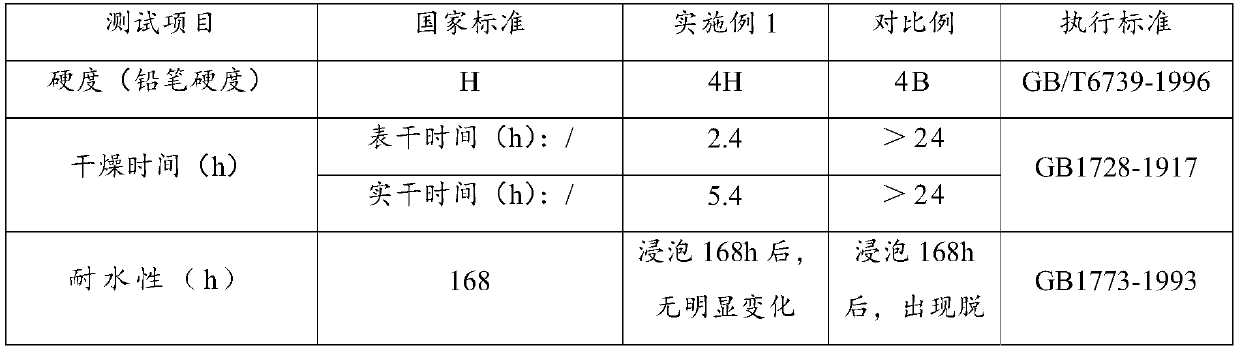

Embodiment 1

[0065] Composite Nano TiO 2 And ZnO water-based epoxy floor surface paint, including four groups of A group, B1 group, B2 group and B3 group:

[0066] A component includes the following components in parts by weight: nano TiO 2 1 part of nano-ZnO, 3 parts of silane coupling agent containing vinyl groups, 18 parts of deionized water;

[0067] Component B1 includes the following components in parts by weight: 0.6 parts of mineral oil defoamer, 0.5 parts of wetting and dispersing agent, and 0.6 parts of pure acrylic leveling agent;

[0068] Component B2 includes the following components in parts by weight: 42 parts of water-based epoxy resin, 4 parts of 2,2,4-methyl-1,3-pentanediol monoisobutyrate, and 6 parts of reactive diluent AGE ;

[0069] Component B3 includes the following components in parts by weight: 10 parts of curing agent triethylenetetramine.

[0070] Nano-TiO 2 The weight ratio of nano-ZnO and water-based epoxy resin is 0.02:1; the weight ratio of nano-ZnO and...

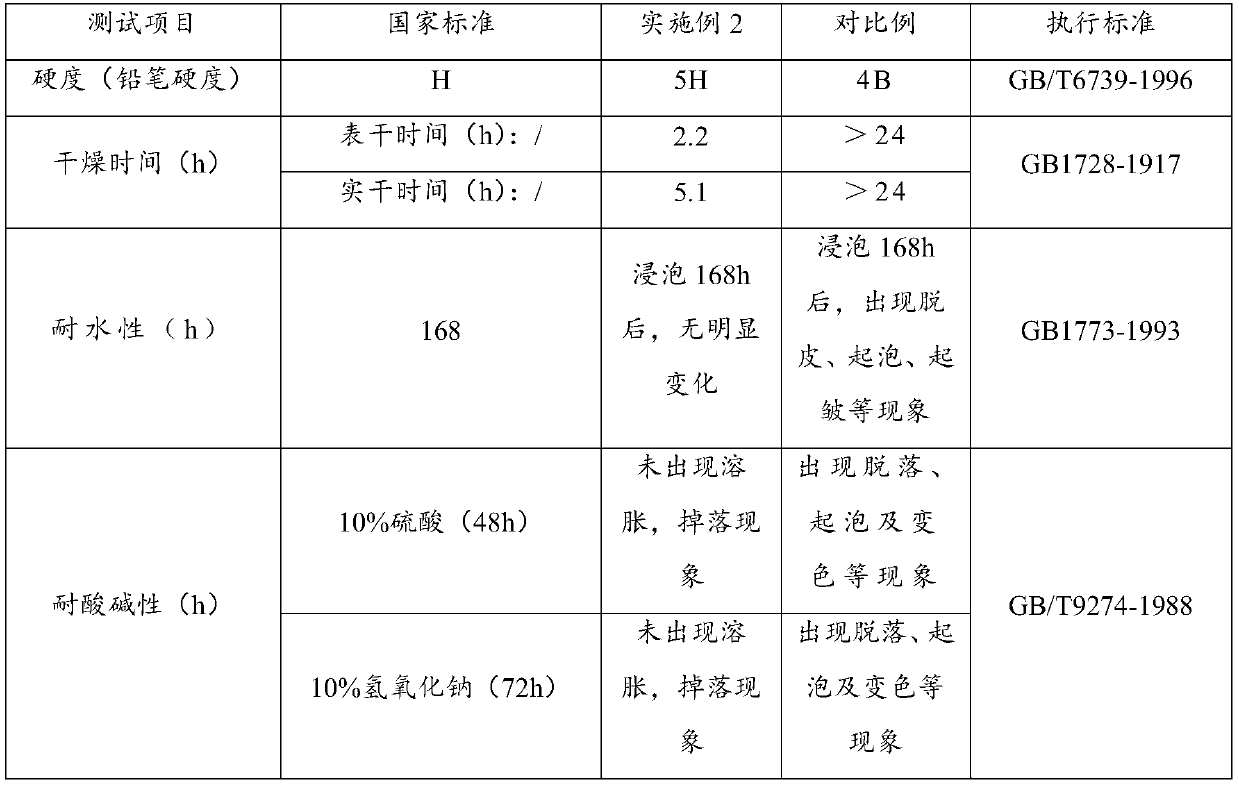

Embodiment 2

[0082] Composite Nano TiO 2 And ZnO water-based epoxy floor surface paint, including four groups of A group, B1 group, B2 group and B3 group:

[0083] A component includes the following components in parts by weight: nano TiO 2 3 parts of nano-ZnO, 1.5 parts of nano-ZnO, 5 parts of silane coupling agent containing amino groups, and 22 parts of deionized water;

[0084] Component B1 includes the following components in parts by weight: 1 part of polydimethylsiloxane defoamer, 1 part of wetting and dispersing agent, and 1.2 parts of modified acrylic leveling agent;

[0085] The B2 component includes the following components in parts by weight: 38 parts of water-based epoxy resin, 6 parts of dodecyl alcohol ester, 10 parts of reactive diluent HK-66;

[0086] Component B3 includes the following components in parts by weight: 16 parts of curing agent diethylenetriamine.

[0087] The weight ratio of nano-ZnO and water-based epoxy resin is 0.04:1; nano-TiO 2 The weight ratio of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com