Clean biomass fuel and preparation method thereof

A biomass fuel and mixture technology, which is applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of high production cost, many pollutants, and low utilization efficiency, and achieve improved combustion calorific value, good comprehensive economic effect, and improved The effect of fuel heating value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

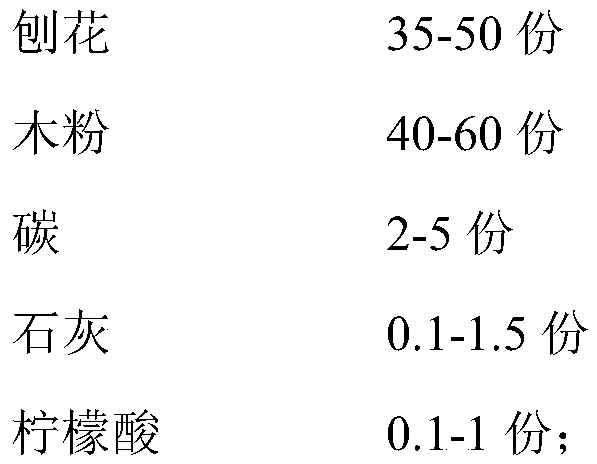

[0032] A clean biomass fuel, in parts by weight, comprises the following components:

[0033]

[0034] The length of the shavings is 5-12mm, the width is 2-6mm, and the thickness is 0.05-2mm.

[0035] The water content of the shavings is less than 12%.

[0036] The particle size of the wood powder is less than 0.2mm, and the water content is less than 14%.

[0037] The particle size of the carbon is less than 0.2mm.

[0038] The particle size of the lime is less than 0.2mm.

[0039] A preparation method of clean biomass fuel, comprising the following steps:

[0040] (1) Mixing: Weigh each component according to the formula, stir and mix the wood shavings, wood flour and citric acid, dry after burning, and prepare the mixture for subsequent use;

[0041] (2) Forming and granulating: add the mixture, carbon and lime prepared in step (1) into a forming machine (provided by Liyang Huasheng Machinery Manufacturing Co., Ltd., model: HS-680) and press to form, then cool to pro...

Embodiment 2

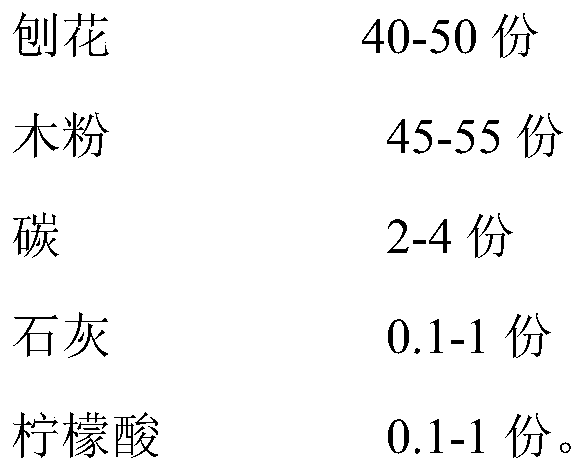

[0046] A clean biomass fuel, in parts by weight, comprises the following components:

[0047]

[0048]

[0049] The length of the shavings is 5-12mm, the width is 2-6mm, and the thickness is 0.05-2mm.

[0050] The water content of the shavings is less than 12%.

[0051] The particle size of the wood powder is less than 0.2mm, and the water content is less than 14%.

[0052] The particle size of the carbon is less than 0.2mm.

[0053] The particle size of the lime is less than 0.2mm.

[0054] A preparation method of clean biomass fuel, comprising the following steps:

[0055] (1) Mixing: Weigh each component according to the formula, stir and mix the wood shavings, wood flour and citric acid, dry after burning, and prepare the mixture for subsequent use;

[0056] (2) Forming and granulating: add the mixture, carbon and lime prepared in step (1) into a forming machine (provided by Liyang Huasheng Machinery Manufacturing Co., Ltd., model: HS-680) and press to form, then...

Embodiment 3

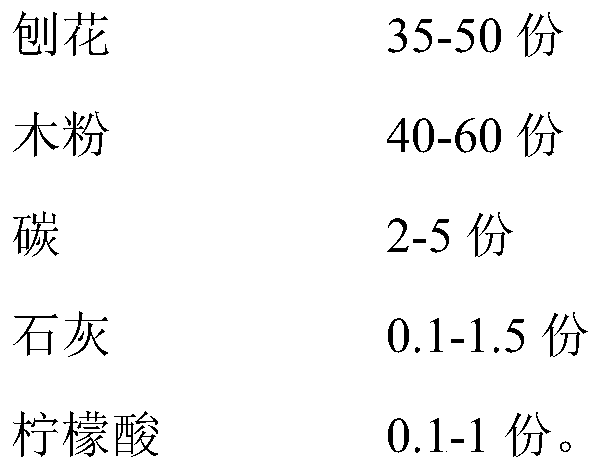

[0061] A clean biomass fuel, in parts by weight, comprises the following components:

[0062]

[0063] The length of the shavings is 5-12mm, the width is 2-6mm, and the thickness is 0.05-2mm.

[0064] The water content of the shavings is less than 12%.

[0065] The particle size of the wood powder is less than 0.2mm, and the water content is less than 14%.

[0066] The particle size of the carbon is less than 0.2mm.

[0067] The particle size of the lime is less than 0.2mm.

[0068] A preparation method of clean biomass fuel, comprising the following steps:

[0069] (1) Mixing: Weigh each component according to the formula, stir and mix the wood shavings, wood flour and citric acid, dry after burning, and prepare the mixture for subsequent use;

[0070] (2) Forming and granulating: add the mixture, carbon and lime prepared in step (1) into a forming machine (provided by Liyang Huasheng Machinery Manufacturing Co., Ltd., model: HS-680) and press to form, then cool to pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com